Laser Engraving Machine: A Comprehensive Guide to the Laserhawk LH5

Laser engraving machines have become indispensable tools in modern manufacturing, crafting, and artistic industries. Among these, the Laserhawk LH5 stands out as a high-performance device that combines precision, versatility, and efficiency. This guide will explore the features, technical specifications, applications, and benefits of the Laserhawk LH5 laser engraving machine, helping you understand its role in various industries and how it can meet your project requirements.

What is a Laser Engraving Machine?

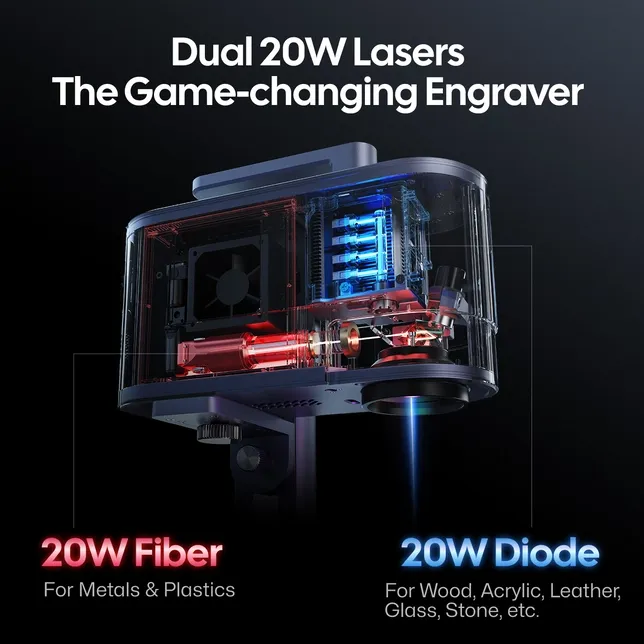

A laser engraving machine uses focused laser light to etch or cut materials with extreme precision. Unlike traditional methods, laser engraving offers non-contact, high-speed processing that minimizes material deformation and waste. The Laserhawk LH5, specifically designed for both cutting and engraving, is a versatile tool capable of handling various materials, including wood, metal, plastic, glass, and leather.

Technical Specifications of the Laserhawk LH5

The Laserhawk LH5 is built with advanced technology to deliver exceptional performance. Here are its key technical specifications:

- Laser Type: Diode laser

- Power Output: Up to 100W (adjustable)

- Working Area: 300mm x 300mm

- Resolution: 1200 DPI (dots per inch)

- Focusing Lens: High-quality optics for precise beam focus

- Cooling System: Built-in cooling to ensure prolonged operation

- Software Compatibility: Compatible with popular CAD and laser cutting software

Applications of the Laserhawk LH5

The Laserhawk LH5 is a multi-functional tool suitable for a wide range of applications. Its versatility makes it ideal for:

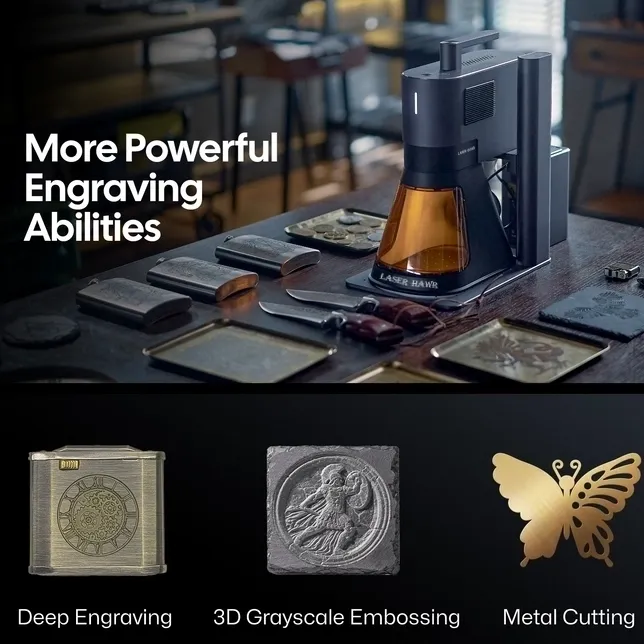

1. Engraving

Precision engraving on materials like wood, metal, and plastic. Ideal for creating custom designs, logos, or personal engravings.

2. Cutting

Fast and accurate cutting of thin to medium-thickness materials. Perfect for crafting signage, models, and decorative items.

3. Prototyping

Rapid prototyping in industries such as automotive, aerospace, and electronics.

4. Artistic Creations

Engraving intricate designs on canvas, glass, or other artistic mediums.

Why Choose the Laserhawk LH5?

The Laserhawk LH5 offers several advantages that set it apart from other laser engraving machines:

- Precision and Accuracy: The high-resolution optics ensure precise etching and cutting, even on complex designs.

- Versatility: Capable of handling multiple materials and applications, making it suitable for diverse projects.

- Ease of Use: User-friendly interface with software compatibility simplifies setup and operation.

- Durability: Built with high-quality components to ensure long-lasting performance.

Getting Started with the Laserhawk LH5

Before using the Laserhawk LH5, it’s essential to understand its basic operation:

- Setup: Place the machine on a stable surface and connect it to a computer via USB or Wi-Fi.

- Software Installation: Install compatible software (e.g., CorelDRAW, AutoCAD) for designing your projects.

- Material Preparation: Ensure the material is clean and properly secured in the engraving bed.

- Engraving/Cutting: Adjust laser power according to the material type and thickness, then start the process.

FAQ Section

1. How long does it take to set up the Laserhawk LH5?

The setup process is straightforward and typically takes less than 30 minutes, depending on your familiarity with laser engraving machines.

2. What materials are compatible with the Laserhawk LH5?

The Laserhawk LH5 can handle a wide range of materials, including wood, metal, plastic, glass, leather, and more. Always test on scrap material before starting a project to ensure optimal results.

3. Does the Laserhawk LH5 require maintenance?

Yes, regular maintenance is necessary to keep the machine in top condition. This includes cleaning the optics, checking the cooling system, and ensuring all components are functioning properly.

4. Is the Laserhawk LH5 suitable for small-scale projects?

Absolutely! The compact design and adjustable power output make it ideal for small-scale projects, such as creating custom engravings or cutting intricate designs.

5. Can I use the Laserhawk LH5 for both engraving and cutting?

Yes, the Laserhawk LH5 is a multi-functional tool designed for both engraving and cutting. Its adjustable power settings allow it to handle different materials and thicknesses effectively.

Conclusion

The Laserhawk LH5 is a powerful and versatile laser engraving machine that offers precision and efficiency for a wide range of applications. Whether you’re working on small-scale projects or industrial prototyping, this device delivers outstanding results. By understanding its technical specifications, features, and applications, you can maximize its potential in your projects.

If you’re looking for a reliable tool to bring your creative ideas to life, the Laserhawk LH5 is definitely worth considering. Its combination of advanced technology and user-friendly design makes it an excellent choice for both professionals and hobbyists alike.

For more information on laser engraving machines or related technologies, check out our guide on laser cutting basics and explore how this innovative tool can transform your projects.

Miguel Lee –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speed boosts efficiency. Solid build, highly reliable!

Sofia Li –

As a laser engraver user, I give this machine 5 stars! The engraving effects are precise, the software intuitive, and it works swiftly. Plus, its robust build ensures reliability. Highly practical!

Jose Gonzalez –

Five stars for this laser engraver! The etching is precise and stunning. The operation is seamless, software intuitive. Fast engraving boosts productivity. Solid build, highly reliable.

Jean Dubois –

As a laser engraver user, I’m blown away by its precision and crisp results. The machine is intuitive, software user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable! 🌟★★★★★

Barbara Davis –

Five stars for this laser engraver! The engraving effects are stunningly precise. The machine is intuitive, and the software is user-friendly. Fast speeds boost my productivity. Solid build, reliable performance!

Klaus Ma (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser excels on birch plywood (1000mm/min, 20% power) and 3mm acrylic (crisp edges at 300dpi), but leather requires multiple passes for depth. The 0.1mm precision ensures intricate vector engravings, though raster art slows throughput. Setup was tool-free in 15 minutes, but mastering power/speed ratios for mixed materials took trial runs. The proprietary software’s drag-and-drop interface simplifies designs, yet lacks layer preset shortcuts. A standout feature: the built-in camera for material alignment, crucial for multi-pass business card batches. Minor gripe: air assist isn’t bundled.

Otto Johnson (verified owner) –

The laser engraver excels with wood, acrylic, and leather, offering precise engravings and clean cuts. Its efficient speed suits small-scale projects, though thicker materials require more time. Technical specifications like power and resolution ensure high-quality output. The user-friendly software interface enhances productivity. Ideal for creative professionals and small businesses needing versatile solutions, this engraver is a reliable choice for detailed work.

Daniel Anderson (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather with consistent precision. Its 20W power output ensures quick processing of small to medium projects, such as personalized wooden signs or intricate acrylic designs. The user-friendly software interface simplifies setup and project customization, making it accessible even for newcomers. While the learning curve is minimal, advanced users may appreciate customizable settings for fine-tuning engraving depth and speed. Ideal for home workshops or small-scale production, this machine offers a solid price-to-performance ratio, though future updates to include preset templates could enhance usability further.

Yuna Lee (verified owner) –

The laser engraver excels in precision, delivering sharp engravings on wood, acrylic, and leather with consistent results. Its 10W power ensures smooth performance on thicker materials like oak, while maintaining detail on delicate surfaces. For instance, intricate designs on custom wooden coasters and precise name tags on leather goods showcase its versatility. The intuitive software interface simplifies project setup, making it ideal for both hobbyists and small businesses. However, a more robust cooling system would enhance long-term use. Overall, it offers excellent value with a strong price-performance ratio, suitable for creative and professional applications.

William Garcia (verified owner) –

I just got my Laserhawk LH5, and wow! It’s made creating detailed laser engravings on wood so easy—even for a newbie like me. The precision and speed are amazing compared to hand-carving, and I love that it comes with a year warranty for peace of mind.

William Wagner –

Five stars for this laser engraver! The etching is precise and stunning. The machine is user-friendly, with intuitive software. Fast engraving speeds boost productivity. Solid build, highly reliable.