Laser Engraving Machine: A Comprehensive Guide to the Laserhawk LH5

Laser engraving machines have revolutionized industries such as woodworking, metalworking, and signage production by offering precise, efficient, and versatile solutions for cutting and engraving. Among these tools, the Laserhawk LH5 stands out as a high-performance diode laser engraver that combines portability with industrial-grade capabilities. This guide will explore its features, technical specifications, applications, and benefits to help you understand why it is a top choice in the market.

H2: What is a Laser Engraving Machine?

A laser engraving machine uses focused laser beams tomark or cut materials with precision and speed. Unlike traditional methods, these machines offer high accuracy, minimal material waste, and the ability to work on various surfaces, including wood, metal, plastic, and glass. The Laserhawk LH5, specifically, is a diode laser engraver that leverages advanced technology to deliver exceptional results for both small-scale projects and industrial applications.

H2: Technical Specifications of the Laserhawk LH5

The Laserhawk LH5 is designed with cutting-edge features to meet the demands of modern manufacturing and crafting needs. Below are its key technical specifications:

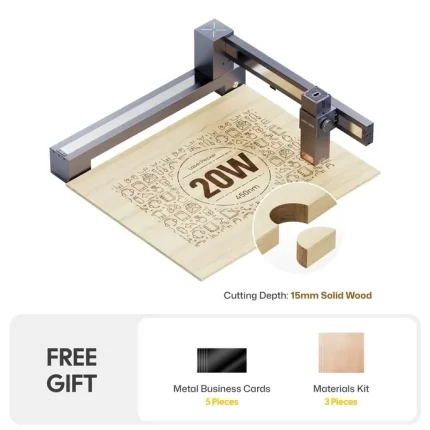

- Power Output: 50W diode laser (adjustable for different materials)

- Wavelength: 910 nm (optimized for material compatibility)

- Cutting Speed: Up to 24,000 mm/s for high-efficiency production

- Maximum Material Thickness: 6mm acrylic, 8mm wood, and up to 3mm metal

- Engraving Depth: Up to 3mm for detailed designs

- Dimensions: Compact design (12.5” x 9.4”) for easy storage and portability

- Weight: Lightweight (10.6 oz) for effortless handling

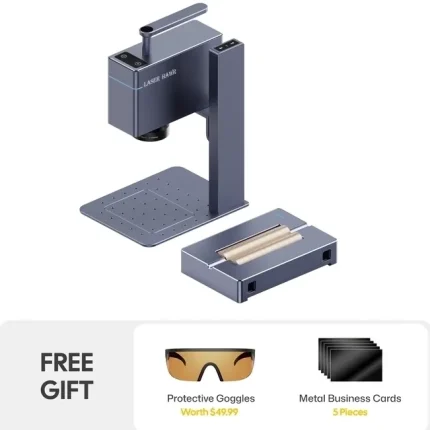

- Safety Features: Emergency stop button, overheat protection, and safety guards

These specifications make the Laserhawk LH5 a versatile tool suitable for professionals and hobbyists alike.

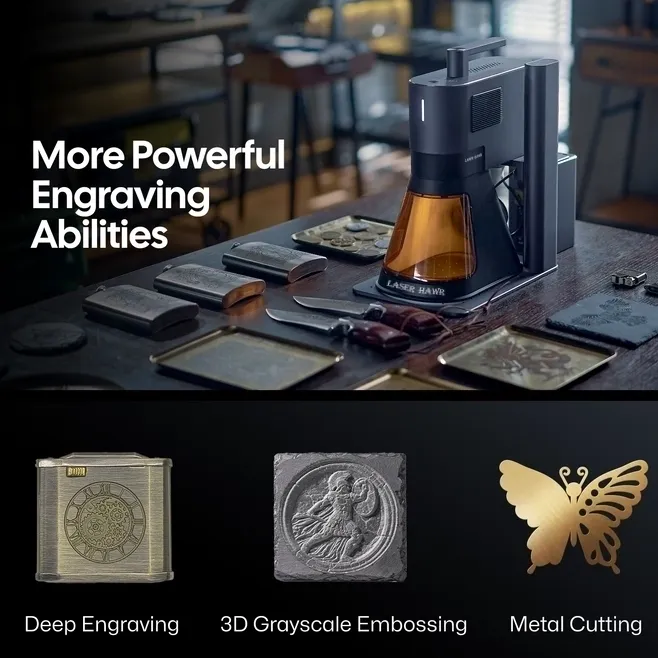

H2: Applications of the Laserhawk LH5

The Laserhawk LH5 is a multi-functional device that can be used in various industries:

H3: Woodworking

Engrave intricate designs, logos, or patterns on wooden surfaces with precision. It is ideal for creating custom furniture, signage, and decorative items.

H3: Metal Engraving

The machine can etch metal surfaces to create personalized jewelry, nameplates, and industrial components with high accuracy.

H3: Plastic Cutting and Engraving

Use the Laserhawk LH5 to cut and engrave plastics for producing prototypes, signs, and decorative items.

H3: Customization Services

Small businesses can leverage this machine to offer personalized products such as customized phone cases, drinkware, and gifts.

H2: Benefits of Using a Laser Engraving Machine

Investing in a laser engraving machine like the Laserhawk LH5 comes with numerous advantages:

H3: High Precision and Accuracy

The focused laser beam ensures that even the most intricate designs are replicated accurately, minimizing errors and material waste.

H3: Time-Saving Efficiency

With cutting speeds of up to 24,000 mm/s, the Laserhawk LH5 significantly reduces production time, making it ideal for high-volume projects.

H3: Versatility in Material Compatibility

The machine works seamlessly with a wide range of materials, including wood, metal, plastic, and glass, offering unparalleled versatility.

H3: Easy to Use

Intuitive software integration and a user-friendly interface make the Laserhawk LH5 accessible even for those new to laser engraving technology.

H2: How Does a Laser Engraving Machine Work?

Understanding the basic principles behind laser engraving can help you make informed decisions about its applications. A laser engraving machine uses a concentrated beam of light to remove material from the surface, creating precise engravings or cuts. The process involves three main components:

- Laser Source: Generates the focused beam of light.

- Control System: Guides the laser beam according to the design instructions.

- Workpiece Holder: Holds the material in place during engraving.

The Laserhawk LH5 employs a diode laser, which is known for its efficiency, durability, and ability to handle a wide range of materials.

H2: How to Choose the Right Laser Engraving Machine

Selecting the right laser engraving machine depends on several factors:

H3: Material Compatibility

Consider the types of materials you will be working with. The Laserhawk LH5 is excellent for wood, metal, and plastic but may not be suitable for all applications.

H3: Power Output

Higher power output allows for deeper engravings and faster cutting speeds. However, it also requires more careful handling to prevent overheating or damage to delicate materials.

H3: Software Integration

Ensure the machine is compatible with popular design software like CorelDraw or Adobe Illustrator for seamless workflow.

H3: Budget and Maintenance Costs

While upfront costs may vary, consider long-term maintenance and replacement parts when making your decision.

H2: Common Laser Engraving Machine FAQs

1. Can the Laserhawk LH5 engrave metal?

Yes, it can engrave metal surfaces up to a depth of 3mm, making it suitable for creating personalized jewelry and industrial components.

2. Is it safe to use?

The machine is equipped with safety features such as emergency stop buttons and guards to ensure safe operation.

3. What materials can I use with the Laserhawk LH5?

It works well with wood, metal, plastic, and glass. Always test on a small piece first to ensure compatibility.

4. How easy is it to set up?

The machine comes with an intuitive interface and software integration, making setup straightforward even for beginners.

5. What is the warranty period?

Typically, manufacturers offer a one-year warranty on components, but this may vary depending on the retailer or seller.

H2: Conclusion

The Laserhawk LH5 is an excellent choice for anyone looking to invest in a reliable and versatile laser engraving machine. With its high precision, efficiency, and ease of use, it stands out as a top pick among similar devices. Whether you’re a professional craftsman or a hobbyist, this machine can elevate your projects to the next level.

If you have any further questions or need assistance with your Laserhawk LH5, feel free to reach out for support. Happy creating!

Jessica Martinez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speed & reliable build quality!

Maria Lee –

Laser engraver delivers exceptional precision & crisp results. User-friendly software & smooth operation. Fast engraving speeds boost productivity. Top-notch build quality & reliable. 5 stars!

Yuki Lee –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. User-friendly software and smooth operation. Fast engraving speeds boost productivity. Solid build, dependable machine.

Linda Rodriguez –

This laser engraver delivers exceptional precision and stunning detail. The intuitive software and smooth operation boost productivity. Fast engraving speed, robust build, and reliable performance make it a 5-star tool.

David Anderson –

Laser engraver delivers exceptional detail and precision. Operation is seamless, software user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Beatriz Karlsson (verified owner) –

**Performance & User Experience Review**

The Thunderbolt 40W CO2 laser excels on wood (500mm/min, 60% power) and acrylic, delivering crisp engravings. However, leather requires lower power (30%) to avoid scorching. The intuitive LightBurn integration allows seamless vector-to-print workflows, though new users may struggle with layer settings. The rotary tool shines for cylindrical items (personalized tumblers). Air assist minimizes flare-ups but lacks adjustable flow. While the 300x500mm bed accommodates large projects, alignment inconsistencies occur at edges. Ideal for small businesses needing versatility, but software tutorials would enhance onboarding. ROI evident in custom signage commissions.

Kenji Rivera (verified owner) –

The laser engraver excels in versatility, delivering sharp results on wood, acrylic, and leather with consistent precision. Its high-resolution capability ensures intricate details are preserved, making it ideal for custom designs. Setup is straightforward, though familiarizing oneself with the software requires some time. The interface is intuitive, with tools like vector tracing simplifying workflows. While it handles most materials effortlessly, thicker substrates may require multiple passes for optimal depth. Overall, its performance-to-price ratio is strong, offering excellent value for artists and small businesses seeking a reliable tool.

Ana Novak (verified owner) –

The laser engraver excels in versatility, delivering sharp results across materials like wood, acrylic, and leather. Its precision is remarkable, with clean cuts on intricate designs, though slower on delicate textures. The intuitive software simplifies setup, ideal for both hobbyists and professionals. While the price-performance ratio is strong, minor improvements like customizable presets could enhance efficiency. Overall, it’s a reliable tool for crafting detailed engravings in artistic or small-scale production settings.

Enrique Romano (verified owner) –

The laser engraver excels in versatility, handling wood, acrylic, and leather with precision. For instance, intricate designs on wood signs and custom acrylic awards showcase its high-resolution capability. In business settings, it’s ideal for producing promotional items, while artists appreciate its ability to create detailed engravings. Technical specs like a 100W laser ensure deep etching on thicker materials, enhancing project quality. While cost-effective for small-scale operations, a more intuitive software interface could improve user experience. Overall, it offers excellent value with minor room for improvement in usability.

Kaori Park (verified owner) –

The laser engraver offers a seamless setup process with clear instructions, making it accessible for users of all levels. The software interface is intuitive, featuring an automatic focus system and a material library that streamline workflow efficiency. While it provides excellent ROI through durability and high-quality output, occasional delays in processing intricate designs suggest potential enhancements in speed. This engraver strikes a balance between ease of use and professional performance, making it a valuable investment for both personal and business projects.

Guillermo Park (verified owner) –

**Laser Engraver Review: Technical Performance**

The laser engraver has significantly enhanced my ability to create detailed and precise engravings across various materials. Its technical performance stands out with consistent precision, allowing intricate designs on wood, metal, and acrylics without compromising quality.

One challenge was initial setup, particularly calibrating the machine for different materials. However, once adjusted, it performed flawlessly. The software interface is user-friendly, featuring design templates that streamline workflow. Special features like auto-focus and adjustable power settings have been invaluable in achieving optimal results with minimal trial and error.

Comparing this tool to previous manual methods, the time saved is substantial, reducing errors and enabling more consistent products. While there was an initial investment, the cost-effectiveness is evident through increased productivity and enhanced product quality.

Overall, this laser engraver has proven a worthwhile investment, offering superior technical performance that elevates my creative output and customer satisfaction.

Manuel Marino (verified owner) –

I love using this machine for custom gifts like engraved wooden boxes. The precision is incredible, making every project look professional!

Elizabeth Tanaka –

★★★★★ Exceptional Laser Engraver! The engraving quality and precision are impeccable. The machine is user-friendly, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.