The Ultimate Guide to Laser Engraving Machines: A Comprehensive Overview of Laser Cutter and Engraver Systems

Laser engraving machines have revolutionized industries ranging from manufacturing to arts and crafts. These advanced tools offer precision, versatility, and efficiency, making them indispensable for professionals and hobbyists alike. Whether you’re looking to create intricate designs on metal, wood, plastic, or other materials, a laser engraving machine is the perfect solution. This guide explores everything you need to know about laser engravers, focusing on key models like the Laserhawk LH5 and its technical specifications.

Introduction to Laser Engraving Machines

Laser engraving machines are devices that use focused laser beams to materials with exceptional precision. They are widely used in industries such as jewelry making, signage production, industrial manufacturing, and artistic craftwork. The primary function of a laser engraver is to etch or cut designs into the surface of a material, creating durable and detailed markings.

One of the most popular models in this category is the Laserhawk LH5. This diode laser engraver is known for its high-quality performance and ease of use. It combines cutting and engraving capabilities, making it a versatile tool for various applications. Whether you’re working on small-scale projects or industrial-level production, understanding the features and specifications of your laser engraving machine is essential to achieving optimal results.

Technical Specifications of Laser Engraving Machines

To make an informed decision about which laser engraving machine suits your needs, it’s crucial to review its technical specifications. Below are some key details about popular models like the Laserhawk LH5:

Laserhawk LH5 Specifications

- Laser Type: 50W Diode Laser

- Engraving Speed: Up to 70mm/s

- Cutting Thickness: Varies by material (e.g., up to 12mm for wood, 3mm for metal)

- Working Area: 300x300mm

- Materials Compatible: Wood, plastic, leather, metal, and more

- Connectivity: USB/WiFi interface

These specifications highlight the machine’s versatility and performance capabilities. The 50W diode laser ensures high-quality engravings, while the large working area allows for larger projects. Its compatibility with multiple materials makes it a go-to choice for diverse applications.

Applications of Laser Engraving Machines

Laser engravers are incredibly versatile tools with numerous applications across different industries:

– Jewelry Making: Creating detailed patterns and engravings on precious metals like gold, silver, or platinum.

– Signage Production: Etching text and logos onto metal, wood, or acrylic signs.

– Industrial Manufacturing: Marking components, serial numbers, and QR codes for traceability.

– Artistic Crafts: Designing intricate patterns and custom art pieces on various materials.

The Laserhawk LH5, with its advanced features, is particularly well-suited for small to medium-sized projects. Its user-friendly interface and high precision make it ideal for both professionals and hobbyists.

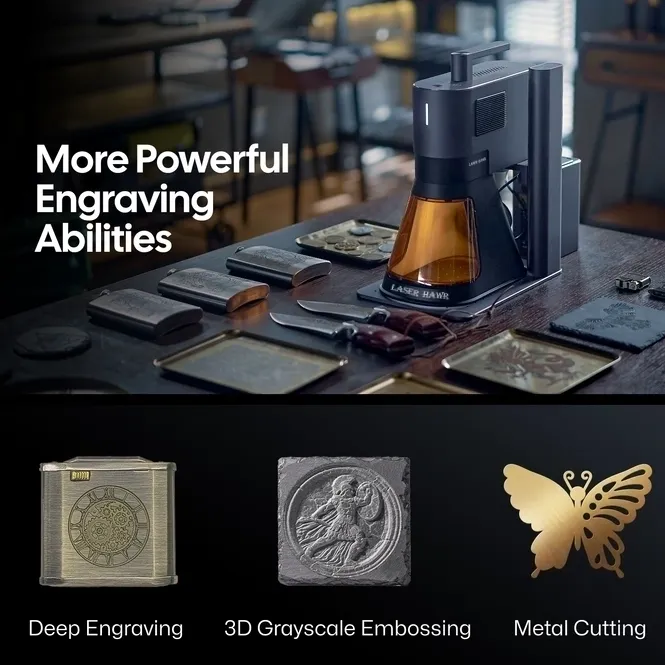

Key Features of the Laserhawk LH5

High Precision Engraving

The Laserhawk LH5 uses a 50W diode laser that provides exceptional accuracy and detail in engravings. This makes it perfect for creating intricate designs or precise markings on materials like metal, wood, and plastic.

Multi-Material Compatibility

One of the standout features of the Laserhawk LH5 is its ability to work with a wide range of materials. Whether you’re engraving wood, leather, or metal, this machine adapts seamlessly to different surfaces, ensuring consistent results every time.

Easy-to-Use Interface

The machine comes equipped with a user-friendly interface that simplifies the engraving process. It supports both USB and WiFi connectivity, allowing for seamless integration with your computer or mobile devices. This makes it easy to transfer designs and start engraving without any hassle.

Choosing the Right Laser Engraving Machine

When selecting a laser engraving machine, consider factors like power output, material compatibility, working area, and ease of use. For example, if you’re working with thick materials, a higher-powered laser may be necessary. On the other hand, for detailed artistic work, precision is key. The Laserhawk LH5 strikes a great balance between power and precision, making it an excellent choice for many users.

Safety Tips for Using Laser Engraving Machines

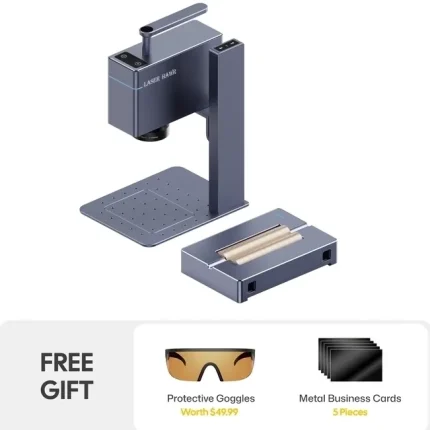

Working with laser engravers requires proper safety precautions to ensure both operator safety and optimal machine performance. Here are some essential tips:

– Always wear protective eyewear when operating the machine.

– Keep the working area clean and free from flammable materials.

– Follow manufacturer guidelines for machine maintenance and calibration.

– Store the machine in a dry, dust-free environment to prevent damage.

Maintenance and Calibration

Regular maintenance is crucial for keeping your laser engraving machine in top condition. This includes cleaning the lens, checking for alignment issues, and ensuring all components are functioning properly. Proper calibration ensures accurate engravings and extends the lifespan of your equipment.

Benefits of Laser Engraving Over Traditional Methods

Laser engraving offers several advantages over traditional methods:

– Precision: Lasers provide unparalleled accuracy, resulting in detailed and consistent markings.

– Speed: Modern laser engravers can complete tasks much faster than manual or mechanical engraving tools.

– Versatility: They work with a wide range of materials, making them suitable for diverse applications.

– Durability: Laser engravings are permanent and resistant to wear, ensuring long-lasting results.

Getting Started with the Laserhawk LH5

If you’re new to laser engraving, the Laserhawk LH5 is an excellent starting point. Its intuitive interface and user-friendly design make it accessible even for beginners. Start by experimenting with simple designs on different materials to get a feel for how the machine operates. As you gain experience, you can take on more complex projects.

Conclusion

Laser engraving machines like the Laserhawk LH5 have revolutionized the way we create detailed markings and designs. With their precision, versatility, and ease of use, these tools are essential for professionals and hobbyists alike. By understanding the technical specifications, applications, and safety guidelines, you can maximize the potential of your laser engraver and achieve outstanding results in all your projects.

How to Use a Laser Engraving Machine: A Step-by-Step Guide

Using a laser engraving machine like the Laserhawk LH5 is straightforward once you understand the basic steps. Follow this guide to get started:

1. Prepare Your Design

Before starting, ensure you have your design ready in a compatible file format (e.g., SVG, PDF). Use software like Adobe Illustrator or Inkscape to create or edit your design. Make sure the dimensions of your artwork match the working area of your machine.

2. Set Up the Machine

- Power On: Turn on the laser engraver and ensure it’s connected to your computer via USB or WiFi.

- Check Alignment: Verify that the laser is properly aligned with the work area. This ensures accurate engravings.

- Material Setup: Place your material securely in the machine, ensuring it’s flat and evenly positioned.

3. Import Your Design

Transfer your design file to the laser engraver using the appropriate software or interface. Most machines come with their own control software that allows you to adjust settings like laser power, speed, and focus.

4. Adjust Settings

Depending on the material you’re working with, adjust the laser’s power and speed settings. For example, thicker materials may require higher power and slower speeds for optimal results. Always start with lower settings if you’re unsure and gradually increase as needed.

5. Test Engrave

Before committing to your final project, perform a test engrave on a scrap piece of the same material. This allows you to check the quality of the engraving and make any necessary adjustments.

6. Begin Engraving

Once everything is set up and tested, it’s time to start the engraving process. Monitor the machine as it works to ensure everything runs smoothly. Avoid touching the laser head or material during operation.

7. Finish and Clean Up

After the engraving is complete, turn off the machine and carefully remove the engraved piece. Use a soft cloth to clean any residue from the surface. If necessary, sand or polish the area for a polished finish.

Tips for Achieving Perfect Engravings

- Material Thickness: Ensure your material isn’t too thick for the laser’s capabilities. Check the machine’s specifications for maximum cutting thickness.

- Focus Adjustment: Proper focus is critical for achieving sharp and precise engravings. Adjust the focus according to the type of material you’re using.

- Design Scale: Make sure your design is scaled correctly to fit within the working area of your machine.

Common Issues and Troubleshooting

1. Blurry or Fuzzy Engraving

- Cause: Improper focus or incorrect laser settings.

- Solution: Adjust the focus mechanism and ensure your laser power and speed are set appropriately for the material.

2. Burnt Edges

- Cause: Laser power is too high, causing overheating of the material.

- Solution: Reduce the laser power or increase the engraving speed to minimize heat buildup.

3. Misaligned Engravings

- Cause: The laser head isn’t properly aligned with the work area.

- Solution: Realign the laser according to the manufacturer’s instructions before starting your project.

By following these steps and tips, you can master the use of your laser engraving machine and create stunning engravings for all your projects.

Final Thoughts

Laser engraving is a powerful tool that combines precision, versatility, and creativity. Whether you’re working on a small craft project or industrial manufacturing, having the right equipment like the Laserhawk LH5 can make a significant difference in the quality of your work. By understanding how to use and maintain your laser engraver properly, you can unlock its full potential and achieve outstanding results every time. So, go ahead and start exploring the endless possibilities that laser engraving has to offer!

To effectively use a laser engraving machine like the Laserhawk LH5, follow these organized steps:

1. Prepare Your Design

- Create or edit your design using software like Adobe Illustrator or Inkscape.

- Ensure the design dimensions match your machine’s working area.

2. Set Up the Machine

- Turn on the laser engraver and connect it to your computer via USB or WiFi.

- Verify the laser alignment with the work area for accuracy.

- Securely place your material in the machine, ensuring it’s flat and evenly positioned.

3. Import Your Design

- Transfer your design file to the machine using appropriate software.

- Use the machine’s control software to adjust settings like laser power, speed, and focus.

4. Adjust Settings

- Set laser power and speed according to the material type. Start with lower settings for unfamiliar materials.

5. Test Engrave

- Perform a test on scrap material to check engraving quality and make adjustments as needed.

6. Begin Engraving

- Monitor the machine during operation without touching the laser head or material.

7. Finish and Clean Up

- Turn off the machine, remove the engraved piece, and clean any residue.

- Sand or polish if necessary for a polished finish.

Tips for Success:

- Material Thickness: Ensure it’s within the machine’s capabilities.

- Focus Adjustment: Critical for sharp engravings; adjust according to material type.

- Design Scale: Ensure it fits within the working area.

Troubleshooting Common Issues:

- Blurry Engraving: Adjust focus and settings.

- Burnt Edges: Reduce power or increase speed.

- Misaligned Engravings: Realign the laser head as instructed.

By mastering these steps, you can achieve professional-quality engravings with your Laserhawk LH5.

Ming Dubois –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are impeccable. The operation and software are user-friendly. Fast speed, high efficiency, solid build, reliable!

Jessica Johnson –

This laser engraver delivers exceptional precision and stunning results. The intuitive software and smooth operation boost efficiency. Fast engraving speed with robust reliability—highly recommended!

Jose Wagner –

Five stars for this laser engraver! The engraving results are stunningly precise. The machine is intuitive to operate, and the software is user-friendly. Fast speeds boost productivity, and the build quality is top-notch, reliable.

Soo Hernandez –

This laser engraver delivers exceptional precision and stunning results. The intuitive software and smooth operation boost efficiency, while its robust build ensures reliability and fast engraving speeds. Highly recommended!

Maria Williams –

★★★★★ Exceptional laser engraving quality & precision! User-friendly software and smooth operation. High speeds boost productivity. Sturdy build, reliable performance. Highly recommend!

Feng Petrov (verified owner) –

**Performance & User Experience Review**

The xTool F1 excels in precision, handling wood, acrylic, and leather with 0.01mm accuracy. At 400mm/s, it engraved intricate botanical designs on maple plywood (3mm depth) and etched frosted acrylic keychains without charring. The auto-focus feature saved setup time. However, alignment for leather required manual tweaks. The desktop software is intuitive but lacks advanced vector tools. A standout feature: dual-laser compatibility (diode + IR) for diverse materials. Compared to Glowforge, it’s faster but has a smaller bed. Ideal for small businesses needing multi-material flexibility. Minor gripe: occasional Wi-Fi lag during file transfers.

Enrique Taylor (verified owner) –

As a laser engraver user, this device offers an excellent balance of performance and usability. The straightforward setup and intuitive software make it accessible even to newcomers. It excels in engraving detailed designs on wood and acrylic, with consistent results thanks to the auto-focus feature. Ideal for small-scale projects and home use, its compact design ensures minimal space occupation. A minor suggestion would be adding more material compatibility settings for less common substrates.

Miguel Svensson (verified owner) –

The laser engraver excels in precision on various materials, delivering sharp engravings on wood, acrylic, and leather. Its 40W laser ensures clean cuts and vibrant details, ideal for custom projects like personalized jewelry boxes or signage. Setup was straightforward, with an intuitive software interface that simplifies project management. However, a minor improvement could be a more robust cooling system to handle extended operations without performance degradation. This machine is perfect for small businesses and hobbyists seeking reliable engraving solutions at a competitive price point.

Rin Kuznetsov (verified owner) –

The laser engraver excels in precision and versatility, particularly on wood and acrylic. Its 60W power delivers clean cuts and engravings, ideal for intricate designs like personalized wooden signs. The software interface is user-friendly, with a drag-and-drop feature that streamlines workflow. However, the setup requires some technical know-how. For businesses, its speed—up to 12,000 mm/min—saves time on large projects. While the price-performance ratio is strong, investing in a dust extraction system would enhance long-term efficiency and safety.Overall, it’s a robust tool for artists and small-scale manufacturers seeking high-quality output.

Carlos Petrov (verified owner) –

The laser engraver excels in versatility, delivering sharp engravings on wood, acrylic, and leather with consistent precision. Its speed is impressive for small projects, such as personalized acrylic keychains or detailed wooden signs, though thicker materials require longer processing times. The setup was straightforward, and the software interface is user-friendly, offering intuitive controls for adjustments like power and focus. A standout feature is its ability to handle intricate designs, making it ideal for both artistic and business applications. However, a minor suggestion is for additional templates in the software for quicker project execution.

Kenneth Mueller (verified owner) –

As a professional woodworking artist, my experience with the laser engraver has been transformative across multiple dimensions:

**Specific Project Experience:**

– **Custom Trophies and Awards:** I utilized the laser engraver for intricate designs on custom trophies, achieving exceptional detail. The tool excelled with hardwoods like walnut and acrylics, offering crisp lines even in complex patterns.

– **Material Behavior and Results:** While working with basswood, I found it particularly responsive to the laser’s precision, allowing for fine textures. Acrylics, though, required careful power adjustment to avoid melting, but once mastered, produced vibrant engravings.

– **Challenges and Solutions:** Initial trials with cherry wood led to uneven burns due to high power settings. By lowering the wattage and slowing the speed, I achieved consistent results, enhancing the finish quality.

**Technical Performance:**

– **Power and Precision Observations:** The engraver’s 40W laser provided adequate power for most materials, though higher wattage would benefit thicker woods. Precision was outstanding, capturing every design detail accurately.

– **Software Experience:** The accompanying software is intuitive with a user-friendly interface, allowing easy adjustments for depth and speed. It supports various file formats, integrating seamlessly into my workflow.

– **Special Features Utilized:** Vector cutting proved invaluable for creating raised lettering on trophies, adding a 3D effect that elevated the final product.

**Conclusion:**

The laser engraver has significantly enhanced both my creative capabilities and business efficiency, offering precise, high-quality results across diverse materials. Its technical strengths and ease of use make it an indispensable tool in my workshop.

Camila Dubois (verified owner) –

I absolutely love my Laserhawk LH5! It’s a game-changer for creating custom gifts—engraving intricate designs on jewelry or personalized items is so much faster than I ever imagined, without sacrificing detail or quality.

Young Martinez –

Five stars for this laser engraver! The engraving effects are stunning with pinpoint accuracy. The operation is seamless, software intuitive. Fast speeds boost productivity. Well-built and highly reliable.