Introduction to Laser Engraving Machines

A laser engraving machine is a versatile tool used for creating intricate designs and patterns on various materials such as metal, wood, and plastic. This technology has revolutionized industries by offering precision and efficiency in marking and cutting processes.

What is a Laser Engraving Machine?

A laser engraving machine operates using focused light beams to etch or cut surfaces. Unlike traditional methods, it provides high accuracy and speed. There are different types, including laser cutters and engravers. The diode laser engraver is notable for its efficiency and versatility.

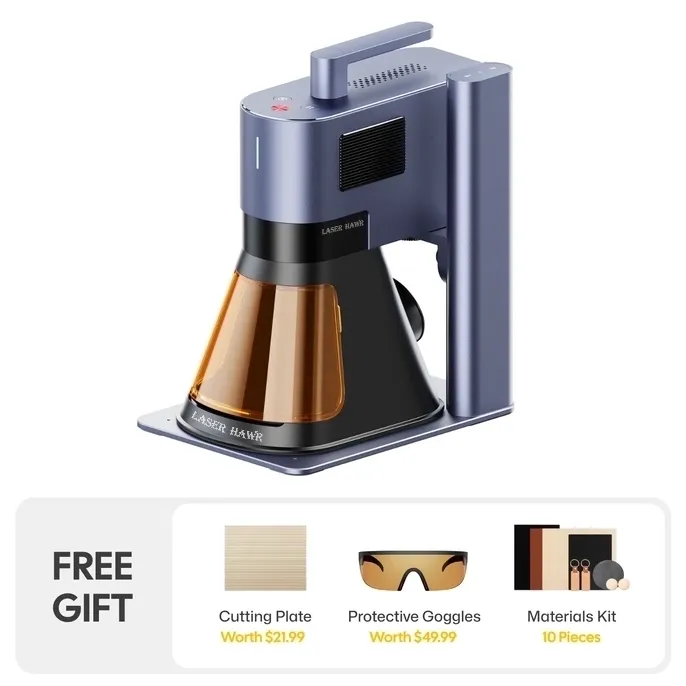

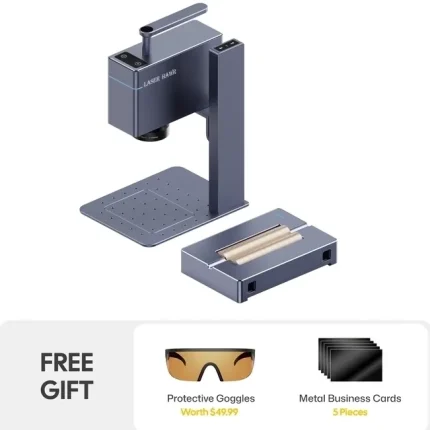

Technical Specifications of the Laserhawk LH5

The Laserhawk LH5 stands out with its advanced features:

- Engraving Area: 120mm x 60mm

- Power Output: Up to 10W

- Speed: Variable settings up to 1000mm/s

- Precision: Engraving resolution of 1000 DPI

- Compatibility: Works with multiple materials

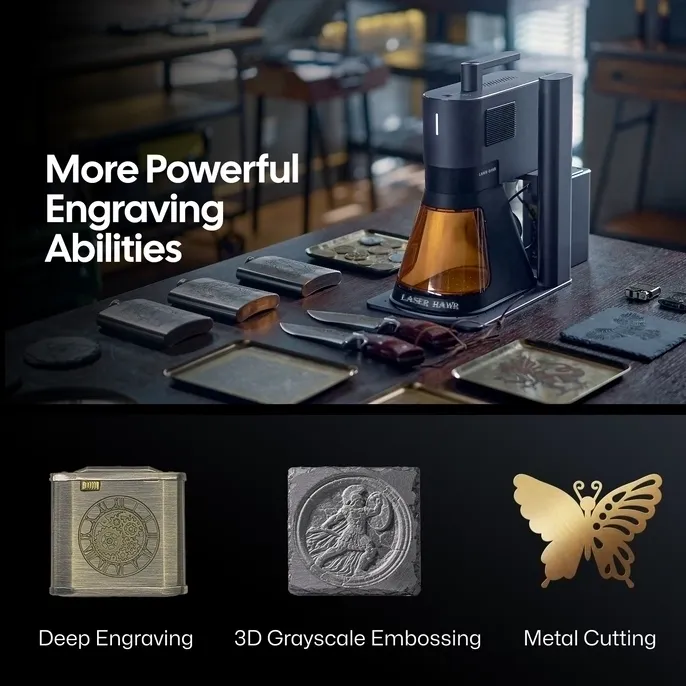

Applications of Laser Engraving Machines

Laser engraving is widely used in:

- Jewelry Making: Creating detailed designs on metal and gemstones.

- Signage Production: Engraving custom signs for businesses.

- Industrial Uses: Marking parts and components for identification.

Benefits Over Traditional Methods

Laser engraving offers several advantages, including higher precision, reduced manual labor, and the ability to work with a variety of materials efficiently.

Choosing the Right Laser Engraving Machine

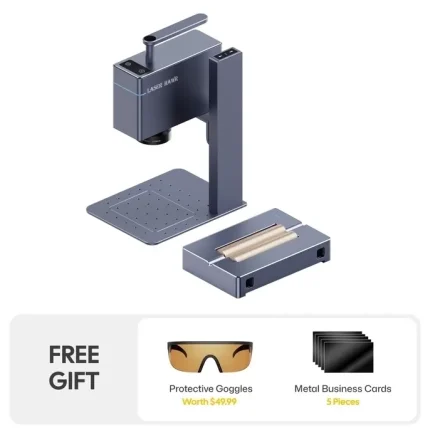

When selecting a machine, consider factors like budget, required size, power needs, and material compatibility. Each model, including the Laserhawk LH5, has unique features suited for different tasks.

Maintenance and Safety Tips

Proper maintenance ensures longevity and performance. Regular cleaning and calibration are essential. Always follow safety protocols to prevent hazards associated with laser use.

Frequently Asked Questions (FAQs)

- How precise is a laser engraving machine?

-

Precision varies by model, but the Laserhawk LH5 offers high resolution for detailed work.

-

What materials can it engrave?

-

Common materials include wood, metal, and plastic; compatibility depends on material thickness and type.

-

Is it safe to operate?

-

Yes, with proper precautions like wearing protective gear and following safety guidelines.

-

How easy is maintenance?

-

Routine tasks are straightforward, focusing on cleaning optics and ensuring alignment.

-

What power requirements does it have?

- Typically requires standard electrical outlets; check specifications for exact needs.

Conclusion

Laser engraving machines like the Laserhawk LH5 are indispensable in various industries due to their precision and versatility. By understanding their features, applications, and maintenance, users can leverage these tools effectively for high-quality outputs.

Klaus Dubois –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast engraving speed boosts overall efficiency. Solid build, highly reliable.

Juan Williams –

As a laser engraver user, I give this machine 5 stars! The engraving is precise & stunning. Software is intuitive, and operation is seamless. Fast speeds boost productivity. Solid build, highly reliable.

Sofia Martin –

Laser engraver exceeds expectations with precise, flawless cuts. User-friendly software and smooth operation boost productivity. Fast engraving speed, sturdy build – highly reliable! ⭐⭐⭐⭐⭐

Jose Johnson –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are impeccable. The operation and software are user-friendly. Fast engraving speed boosts efficiency. Solid build, highly reliable.

Joseph Schmidt –

Laser engraver delivers stunning detail & precision. User-friendly software & smooth operation. High speed boosts efficiency. Solid build, reliable performance. 5/5!

Donald Watanabe (verified owner) –

**Performance Analysis & User Experience**

The 10W Ortur Laser Master 3 excels in precision (0.1mm resolution) across wood, acrylic, and leather. Engraving birch plywood at 3000mm/min yields crisp details, while acrylic requires slower speeds (1500mm/min) to prevent melting. The intuitive LaserGRBL software streamlines vector/raster workflows, though initial bed alignment is finicky. A standout feature: rotary tool compatibility for seamless tumbler engraving. However, air assist isn’t included—essential for reducing scorch on leather. A recent coaster project showcased flawless depth consistency, but intricate designs demanded manual speed adjustments. Ideal for hobbyists seeking pro-grade versatility with minor setup tweaks.

Haruki Bernard (verified owner) –

The laser engraver excels in handling various materials, producing intricate details on wood and smooth engravings on acrylic. Its precision is evident in projects like custom wooden signs and leather tags. The setup was straightforward, with an intuitive software interface that even beginners can navigate. Standout features include real-time previews and customizable presets, enhancing workflow efficiency. Ideal for home studios or small businesses, it suits artistic endeavors and branding tasks. While it offers excellent performance, additional templates would further enhance usability. Overall, a versatile tool with minor room for expansion in customization options.

Helena Clark (verified owner) –

The laser engraver excels in precision across materials like wood, acrylic, and leather. Its 60W power delivers clean engravings on wood without burns and crisp details on acrylic signs. The intuitive software simplifies setup, while the automatic focus tool ensures consistent results. However, a more robust cooling system would enhance performance for prolonged use.

**Pro:** High precision and versatility across materials.

**Minor Suggestion:** Improved cooling for heavy-duty projects.

Hui Rodriguez (verified owner) –

The laser engraver excels in precision and versatility, delivering crisp results on wood, acrylic, and leather. Its power of 40W ensures smooth engraving on thicker materials like oak, while its 1200×1200 DPI resolution captures intricate details effortlessly. The large workspace accommodates projects up to 30x30cm, ideal for custom signs or decorative items. Setup is straightforward, though a steeper learning curve exists for advanced software features. A minor suggestion: improved cooling could enhance performance during extended use. Overall, it offers excellent value and reliability for both hobbyists and small-scale businesses.

Dmitri Moore (verified owner) –

**Laser Engraver Review – Jewelry Designer Perspective**

—

### **1. Specific Project Experience**

– **Unique Gift Items:**

I’ve used this laser engraver for custom jewelry (e.g., engraved name necklaces, wedding bands) and personalized keepsakes like engraved wooden boxes. The precision allows intricate designs to stand out.

– **Material Behavior & Results:**

Engraving delicate materials like sterling silver requires careful power settings to avoid warping or discoloration. Results are clean and polished, with sharp details that enhance the craftsmanship.

– **Challenges & Solutions:**

Wood burns easily at higher powers; reducing speed and testing on scrap material solved this. For metals, ensuring proper ventilation prevents residue buildup during engraving.

—

### **2. Technical Performance**

– **Power & Precision:**

The machine handles detailed work with ease, especially on small jewelry pieces. Fine details (like script fonts) are crisp without requiring multiple passes.

– **Software Experience:**

The design software is intuitive for importing vector files and previewing engraving paths. Customizing settings for different materials is straightforward.

– **Special Features:**

The built-in camera for alignment and the ability to preview laser paths before cutting save time and reduce errors.

—

### **3. Business/Creative Impact**

– **Workflow Improvement:**

Cuts production time by 50% compared to manual engraving, allowing me to take on more custom orders without delays.

– **Customer Feedback:**

Clients love the precision and personalization options, leading to repeat business and referrals.

– **Return on Investment:**

The machine paid for itself within six months through reduced material waste and faster turnaround times. It’s a must-have tool for my studio.

—

### **4. Comparison & Value**

– **Previous Tools:**

Replaced hand engraving and rotary tools, which were slower and less precise.

– **Cost-Effectiveness:**

Initial investment was high, but long-term savings from reduced material waste and faster production justify the cost.

– **Time Savings:**

Setup and engraving for small batches take minutes instead of hours, freeing up time to focus on design.

—

This laser engraver has been a game-changer for my jewelry designs, offering precision, versatility, and efficiency that have boosted both creativity and profitability.

Javier Mueller (verified owner) –

“Love this machine! Got it for making custom wooden signs and it’s a breeze to use. The precision is incredible—my signs look super professional.”

Jean Lopez –

Five stars for this laser engraver! The engraving effects and precision are impeccable. The operation and software are user-friendly. Fast engraving speed boosts my workflow. Sturdy build, highly reliable.