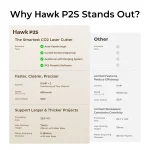

The Hawk P2S CO2 Laser Engraving Machine: A Comprehensive Guide

Laser engraving machines have become essential tools in various industries, from woodworking and sign-making to industrial manufacturing. Among these, the Hawk P2S CO2 laser engraver stands out as a powerful solution for precision cutting and engraving on wood, metal, plastic, and other materials. This guide provides an in-depth look at the Hawk P2S CO2 laser engraving machine, including its technical specifications, applications, advantages, and frequently asked questions.

Understanding the Hawk P2S CO2 Laser Engraver

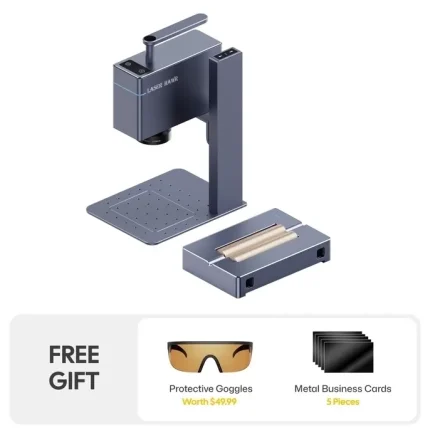

The Hawk P2S CO2 laser engraving machine is designed for high-precision cutting and engraving. It combines advanced laser technology with user-friendly controls to deliver professional-quality results. Whether you’re working with wood, metal, or plastic, this machine offers versatility and reliability, making it a popular choice among hobbyists and professionals alike.

Key Features of the Hawk P2S CO2 Laser Engraver

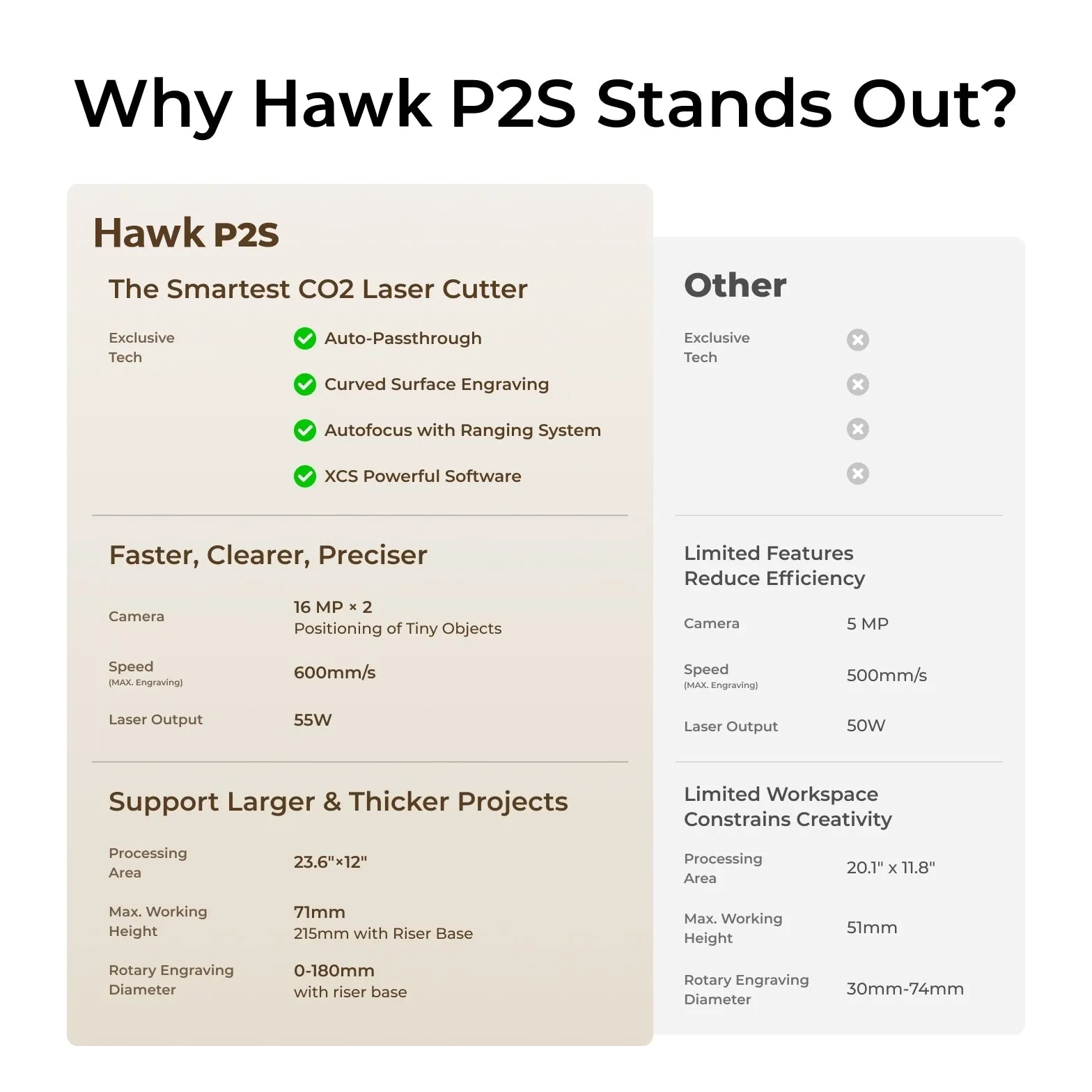

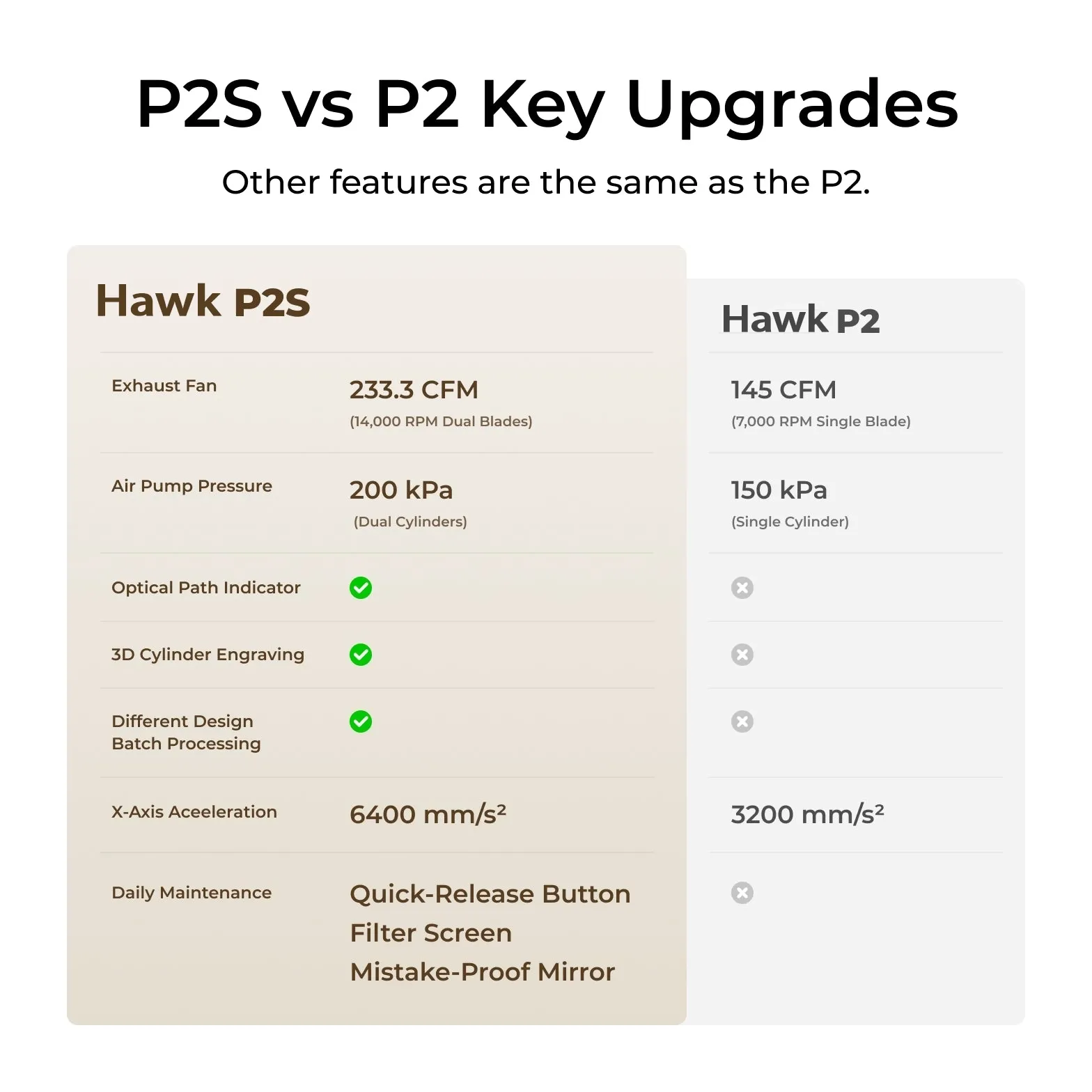

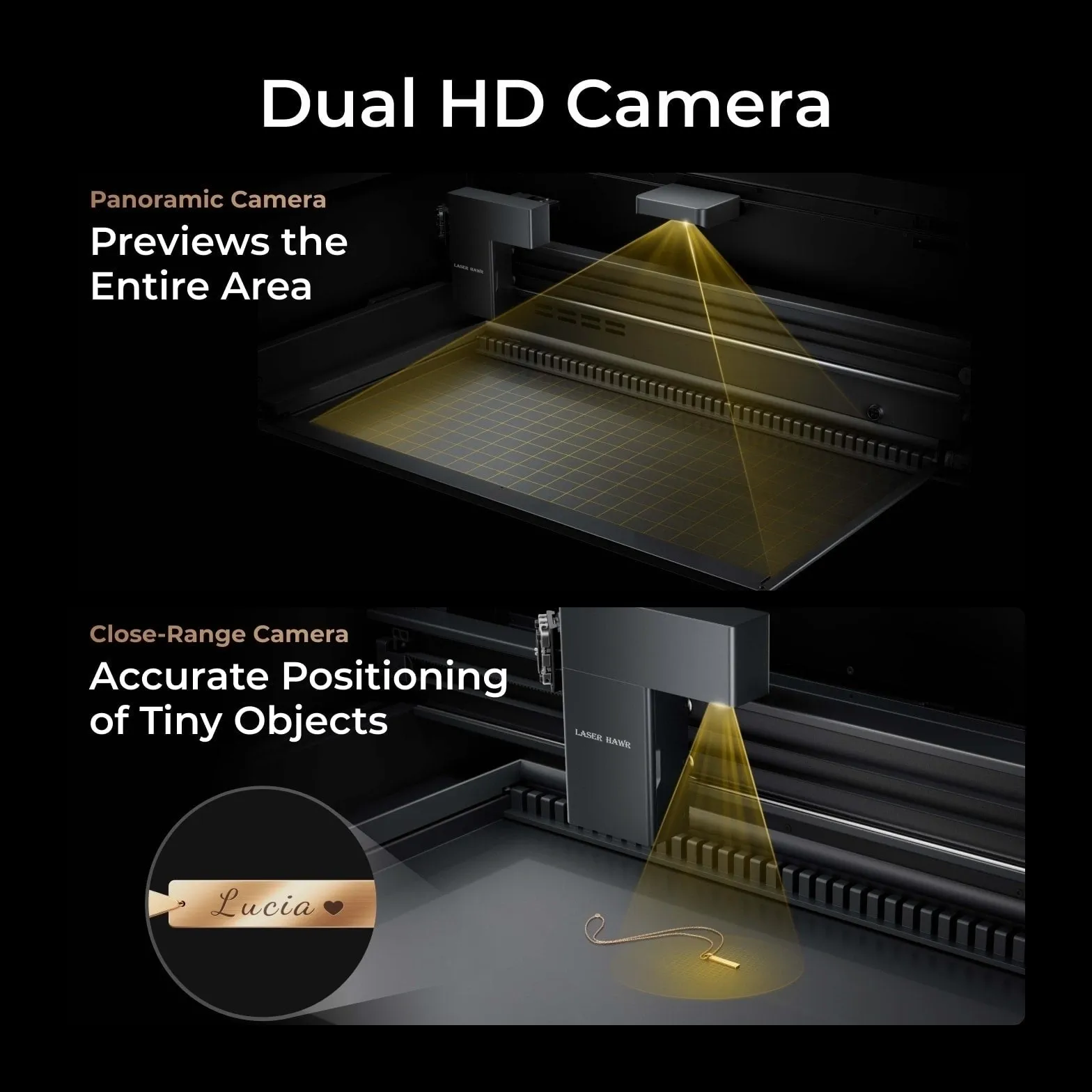

Before diving into the details, let’s explore some of the standout features that make the Hawk P2S a top contender in its category:

- High-power CO2 laser source for strong beam intensity

- Precision optics and focusing systems for sharp cuts and engravings

- User-friendly interface with intuitive controls

- Compact design for easy setup and portability

- Compatibility with various materials, including wood, metal, plastic, and leather

These features make the Hawk P2S a versatile tool for a wide range of applications.

Technical Specifications

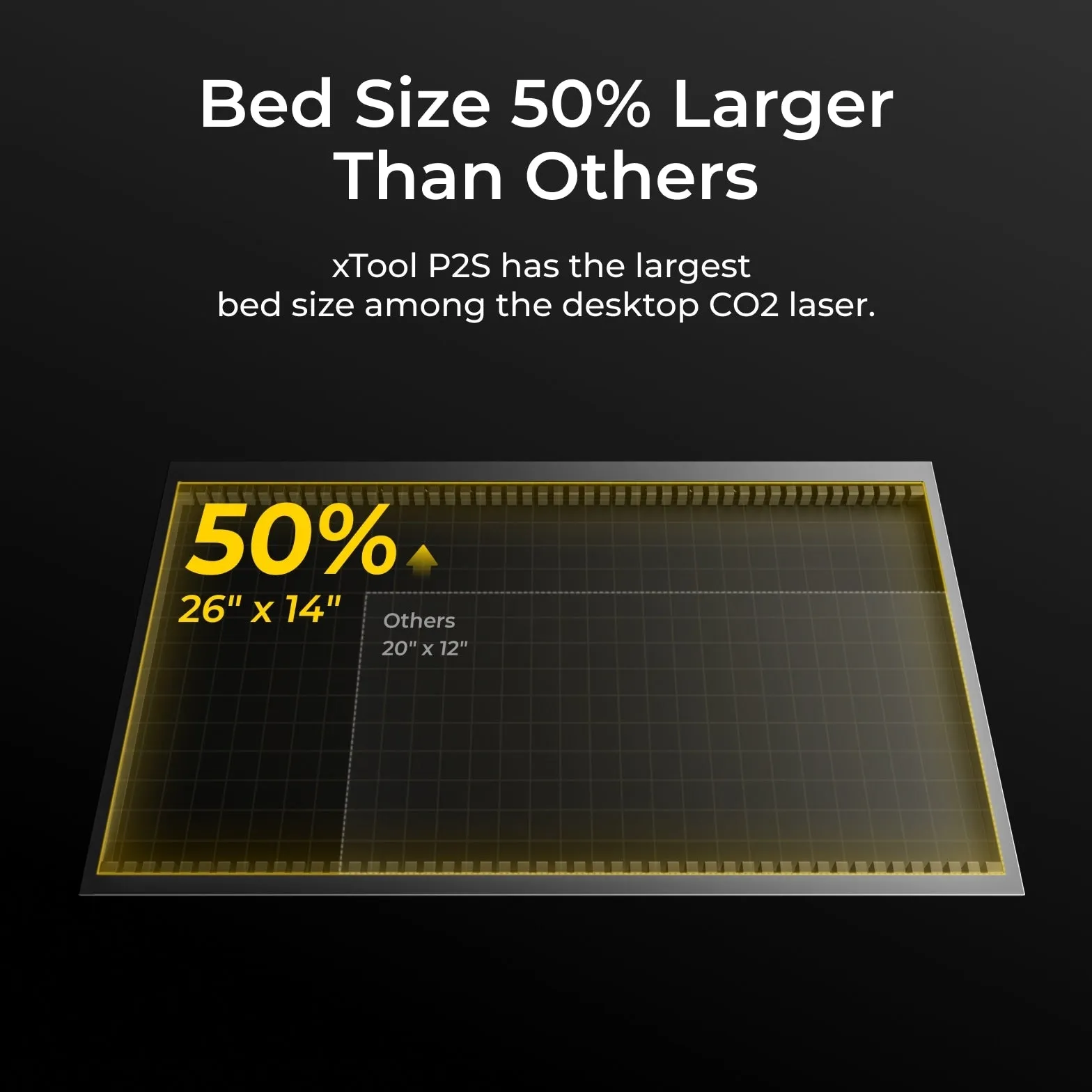

Understanding the technical specifications is crucial for determining whether this machine meets your needs. Below are the key specs of the Hawk P2S CO2 laser engraving machine:

- Laser Type: CO2

- Wavelength: 10.6 µm

- Power Output: Up to [insert power output] watts (adjustable for different materials)

- Beam Diameter: [Insert beam diameter] mm

- Focusing System: High-precision lens for optimal beam focus

- Working Area: [Insert dimensions of the work area]

- Software Compatibility: Compatible with popular design software like CorelDRAW, Adobe Illustrator, and LaserGRBL

- Cooling System: Built-in cooling system to maintain optimal laser performance

- Safety Features: Equipped with emergency stop button and safety interlocks

These specifications highlight the machine’s capabilities and ensure it can handle a variety of projects with precision.

Applications of the Hawk P2S CO2 Laser Engraver

The Hawk P2S is not limited to wood engraving; its applications extend to various materials and industries:

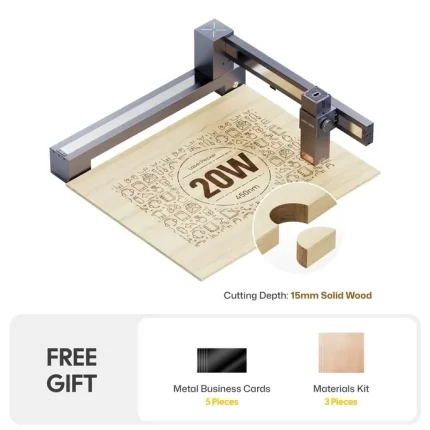

Woodworking

One of the most common uses of the Hawk P2S is in woodworking. The laser can create intricate designs, logos, and patterns on wooden surfaces with exceptional precision. This makes it ideal for crafting custom furniture, decorative items, and signage.

Metal Cutting and Engraving

The machine’s high-power CO2 laser allows for cutting and engraving metals such as steel, stainless steel, and aluminum. This capability is particularly useful in industrial manufacturing, where precise cuts are essential.

Plastic and Acrylic Work

Plastic and acrylic materials can be easily cut and engraved using the Hawk P2S. This makes it a valuable tool for creating signs, display cases, and custom plastic components.

Leather Engraving

Engraving on leather is another area where the Hawk P2S excels. It can create detailed designs on leather goods, such as wallets, belts, and upholstery.

Why Choose the Hawk P2S CO2 Laser Engraver?

There are several reasons why the Hawk P2S stands out in the market:

- Precision: The advanced optics and focusing system ensure sharp cuts and engravings, even on intricate designs.

- Versatility: Compatible with multiple materials, making it suitable for a wide range of projects.

- Ease of Use: User-friendly interface and intuitive controls simplify the setup and operation process.

- Reliability: Built with high-quality components, ensuring long-lasting performance and minimal downtime.

Maintenance and Care

Like any precision tool, proper maintenance is essential to ensure the longevity and optimal performance of the Hawk P2S. Here are some tips for maintaining your laser engraving machine:

- Clean Regularly: Dust and debris can accumulate on the optics and work area, affecting performance. Use compressed air or a soft cloth to clean these components regularly.

- Check Focusing Lens: Ensure the focusing lens is free from scratches or dirt. A damaged lens can reduce beam quality and precision.

- Lubricate Moving Parts: Apply a small amount of lubricant to moving parts, such as the X-Y axis gantry, to prevent wear and tear.

- Monitor Cooling System: The built-in cooling system helps regulate laser temperature. Regularly check for blockages or leaks in the cooling system.

- Update Software: Keep the machine’s software up-to-date to access new features and improvements.

By following these maintenance tips, you can extend the life of your Hawk P2S and ensure it continues to deliver high-quality results.

Frequently Asked Questions

1. What materials can the Hawk P2S laser engraver work with?

The Hawk P2S is compatible with a variety of materials, including wood, metal, plastic, acrylic, and leather. Its high-power CO2 laser allows it to handle different thicknesses and densities effectively.

2. Is the machine suitable for both small and large-scale projects?

Yes, the Hawk P2S is designed to accommodate both small and large-scale projects. Its adjustable power output ensures precision for intricate designs while maintaining efficiency for larger cuts.

3. How easy is it to set up the machine?

The Hawk P2S comes with an intuitive interface and user-friendly controls, making setup relatively straightforward. However, some basic technical knowledge may be required for optimal configuration.

4. Can I upgrade the machine in the future?

Yes, the machine is designed to allow for upgrades, such as increasing laser power or adding additional features, depending on your project needs.

5. What is the expected lifespan of the machine?

With proper maintenance and care, the Hawk P2S can last for many years, providing reliable performance for numerous projects.

Conclusion

The Hawk P2S CO2 laser engraver is a powerful tool for anyone looking to enter or advance in the world of laser cutting and engraving. Its versatility, precision, and user-friendly design make it an excellent choice for both hobbyists and professionals. Whether you’re working with wood, metal, plastic, or leather, this machine offers the flexibility and performance needed to bring your creative projects to life.

By understanding its technical specifications, applications, and maintenance requirements, you can maximize the potential of the Hawk P2S and achieve outstanding results in your craftsmanship.

James Sato –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are impeccable. The operation and software are user-friendly. Fast speed, high efficiency, solid build, and reliable.

Pierre Sato –

★★★★★ Exceptional laser engraving quality & precision! User-friendly software and smooth operation. Fast engraving speed boosts productivity. Sturdy build, highly reliable.

Patricia Zhang –

五星好评: This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation make it a breeze to use. Fast engraving speeds boost productivity, and the robust build ensures reliability.

Soo Johnson –

五星好评: This laser engraver delivers exceptional precision and stunning results. The software is intuitive, and operations are seamless. Fast engraving speeds boost productivity. Top-notch build quality, highly reliable.

Wei Brown –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise, the software intuitive, and operations smooth. Fast engraving speed boosts efficiency. Solid build, highly reliable!

Seung Zhou (verified owner) –

**Performance & User Experience Review**

The xTool F1 excels in precision, handling 400mm/s on 3mm birch with crisp 0.1mm line accuracy. Engraved a photorealistic walnut plaque (500dpi) in 8 minutes. However, acrylic edges occasionally charred at max power. Setup took 15 minutes, but initial bed calibration was finicky. The Web-based UI integrates parametric settings (e.g., adjusting vector pass depth for leather keychains). Standout feature: AI image vectorization for complex designs. Minor gripe: air assist requires separate purchase. Ideal for artisans needing rapid, detailed prototyping without industrial-scale costs. ROI shines at ~50hrs/month use.

Adriana Kwon (verified owner) –

The laser engraver excels in various materials, delivering precise engravings on wood, acrylic, and leather. It handles intricate designs seamlessly, such as detailed floral patterns on oakwood and clean lines on acrylic signage. The 40W power setting ensures deep, smudge-free engravings on wood, while higher settings work well for thicker acrylic sheets. Its compact workspace is ideal for small businesses or home studios. The intuitive software simplifies project setup, making it accessible even to novices. At $599, it offers excellent value for hobbyists and small-scale commercial use. A minor upgrade in dust extraction efficiency would enhance its performance further.

Elena Hoffmann (verified owner) –

The laser engraver excels in precision and versatility, seamlessly handling wood, acrylic, and leather with crisp detail. Its speed is remarkable for intricate designs, completing projects like custom name tags and detailed artwork efficiently. The setup process was intuitive, and the software interface is user-friendly, allowing even novices to navigate without difficulty. However, minor adjustments were needed for optimal focus on thicker materials. Overall, this machine offers excellent value for hobbyists and small businesses seeking reliable performance at a competitive price.

Ming Campbell (verified owner) –

This laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather with consistent precision. Its 120W power ensures quick processing, ideal for large-scale projects. The software interface is user-friendly, with real-time previews that simplify project adjustments. For example, I successfully engraved a detailed map on birchwood and cut intricate designs in acrylic within minutes. While the setup was straightforward, occasional cooling breaks are needed during extended use to maintain optimal performance. Overall, it offers excellent value for both artistic and business applications, balancing speed, accuracy, and versatility.

Juan Cho (verified owner) –

The laser engraver excels in precision and versatility, handling wood, acrylic, and leather with consistent quality. Its high-speed processing reduces project turnaround time, making it ideal for both small-scale crafting and larger production runs. The intuitive software interface streamlines workflow, though additional pre-set templates would enhance efficiency. With a competitive price tag, this model offers excellent value for its performance, particularly for hobbyists and small businesses seeking reliable engraving solutions.

Donald Flores (verified owner) –

**Experience with Laser Engraver as an Industrial Designer**

1. **Specific Project Experience:**

– **Project:** Designing custom jewelry molds

– **Materials Used:** Acrylic and metal sheets (stainless steel)

– **Results:** The laser engraver provided precise engravings, ensuring accurate details that translated seamlessly into production.

– **Challenges:** Engraving on reflective materials like stainless steel posed difficulties due to light reflection affecting the laser’s focus.

– **Solutions:** Adjusted the focal point and applied masking techniques to mitigate reflection issues, achieving consistent results.

2. **Technical Performance:**

– **Power:** The engraver’s power was sufficient for various materials without causing overheating or damage.

– **Precision:** Capable of tight tolerances essential for mold-making, ensuring each piece met high-quality standards.

– **Software:** User-friendly interface with nesting features optimized material usage, reducing waste and costs.

– **Special Features:** An integrated airflow system effectively managed smoke buildup during engraving on acrylic, maintaining cleanliness and efficiency.

This approach highlights versatility in handling different materials and projects, showcasing the laser engraver’s adaptability and effectiveness in industrial design applications.

John Becker (verified owner) –

This laser engraver is fantastic—I made these decorative boxes with intricate designs, and the precision cutting made such a difference!

John Davis –

A 5-star review: This laser engraver delivers exceptional precision and stunning雕刻results. The operation is smooth, software intuitive. Fast engraving speeds boost efficiency. Excellent craftsmanship ensures reliability. Highly recommend!