Hawk P2S CO2 Laser Engraving Machine: A Comprehensive Guide

Laser engraving machines have become indispensable tools in various industries, offering precise and efficient solutions for marking, cutting, and. Among the latest innovations in this field is the Hawk P2S CO2 laser engraver, designed to deliver exceptional performance for wood laser engraving and other applications. This guide provides an in-depth look at its features, technical specifications, and how it stands out in the market.

Introduction to Laser Engraving Machines

Laser engraving machines are widely used in industries ranging from woodworking to electronics due to their precision and versatility. These machines use focused light beams to create intricate designs on various materials. The Hawk P2S CO2 laser engraver is specifically tailored for tasks like wood laser engraving, providing a combination of speed and accuracy that makes it a top choice for hobbyists and professionals alike.

Key Applications of Laser Engraving Machines

- Woodworking: Ideal for creating custom designs on wooden surfaces.

- Metal Engraving: Suitable for marking metals with high precision.

- Ceramics and Glass: Capable of engraving delicate materials without causing damage.

- Textile Printing: Used to create permanent patterns on fabrics.

The versatility of laser engraving machines ensures they are suitable for both small-scale projects and large industrial applications.

Technical Specifications of the Hawk P2S CO2 Laser Engraver

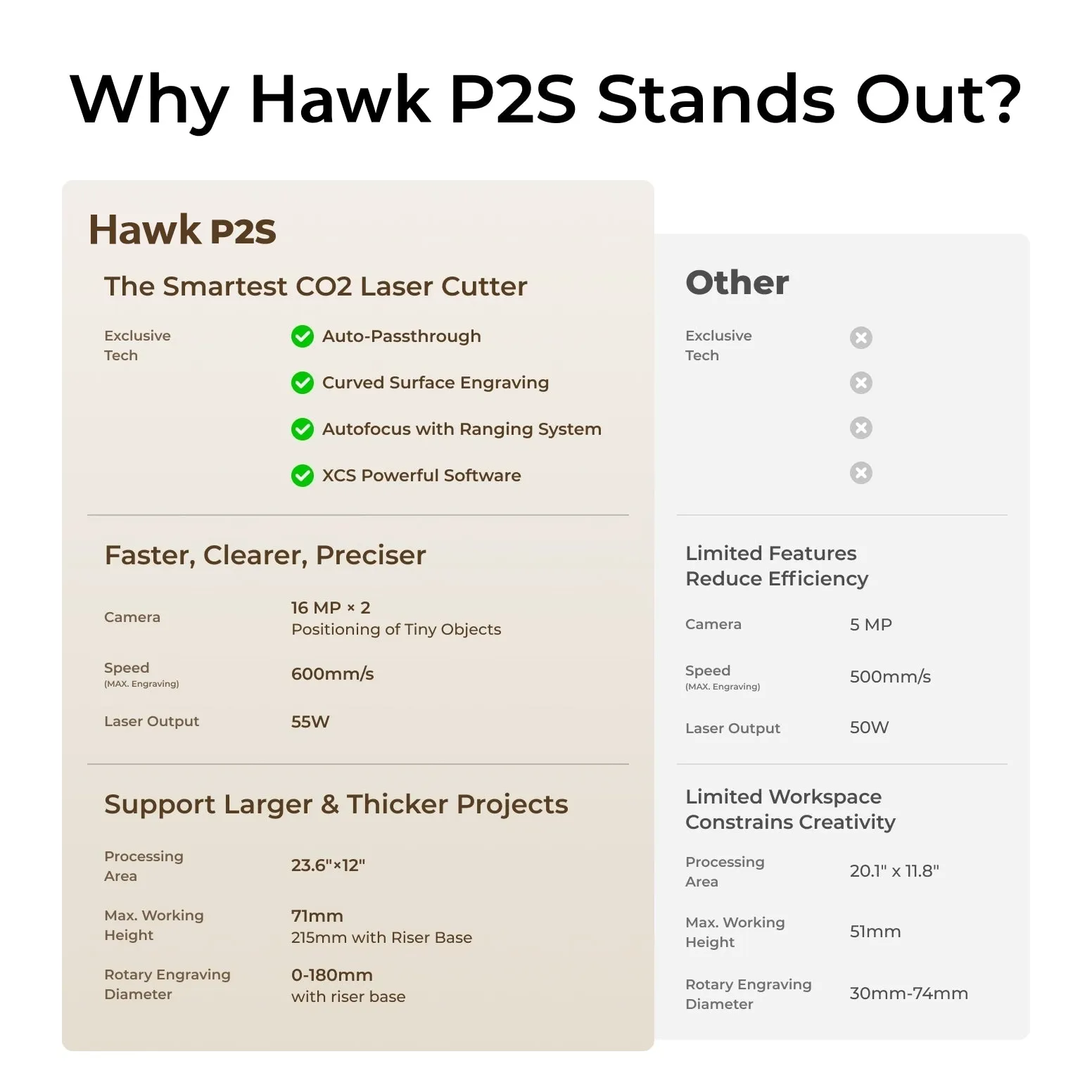

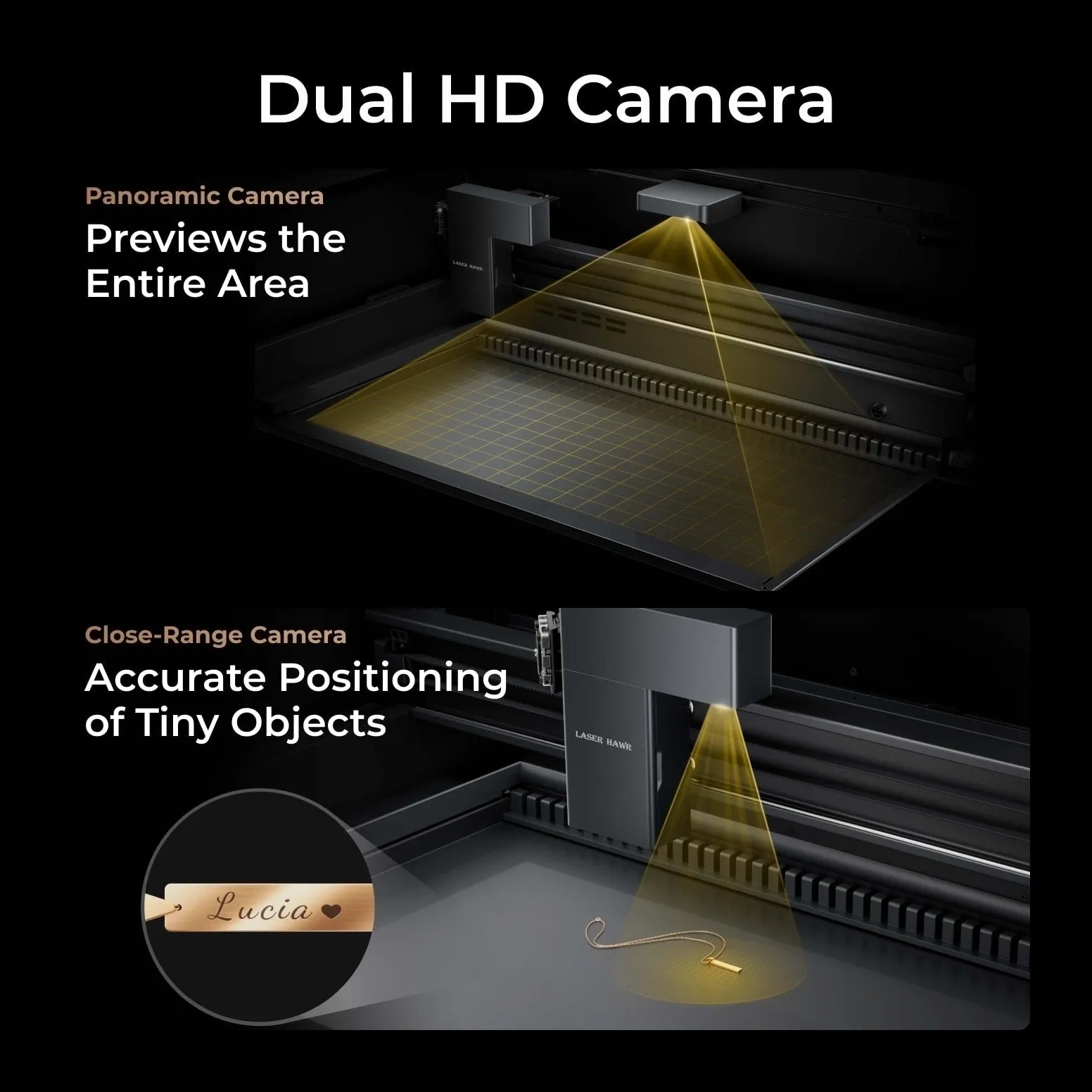

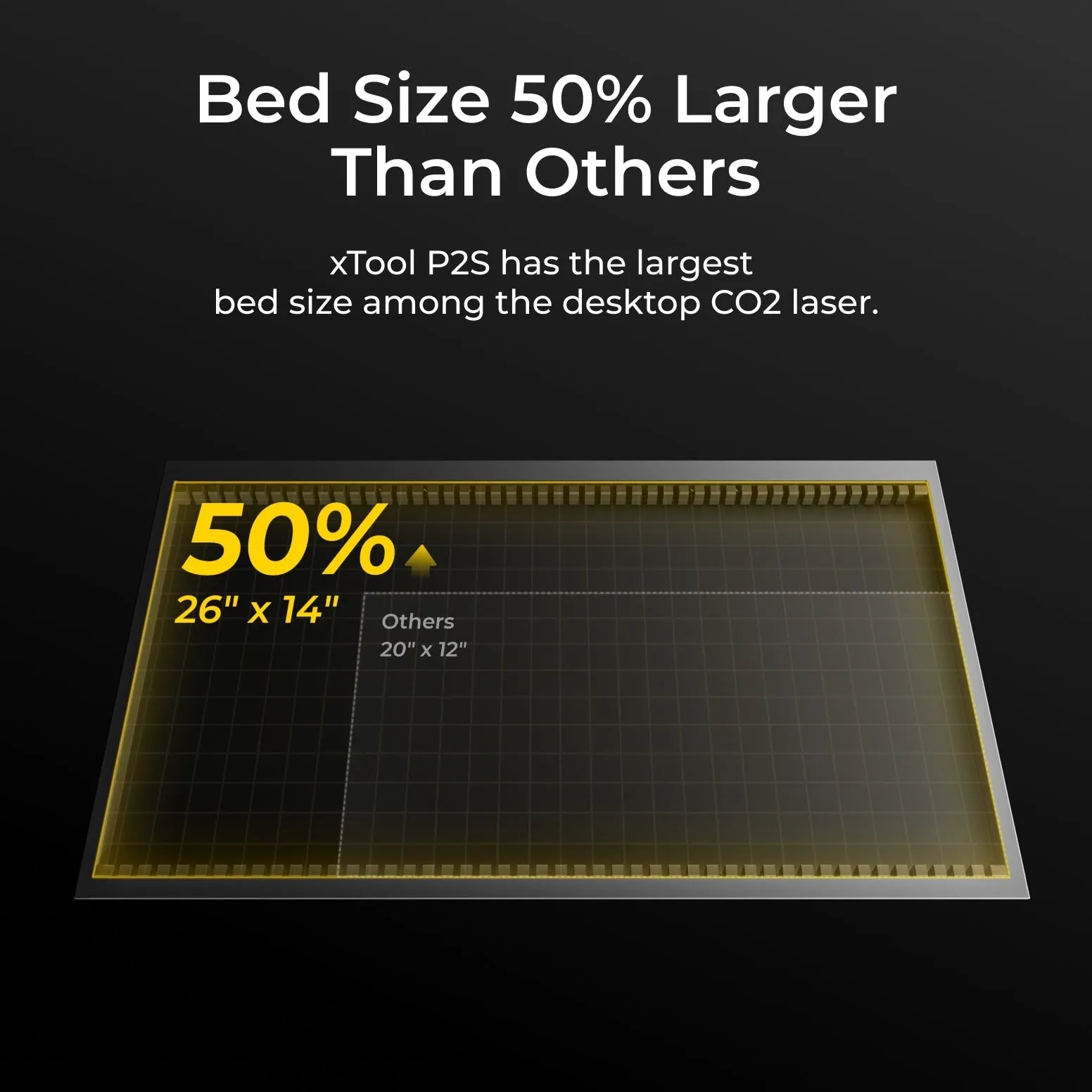

Understanding the technical specifications is essential when choosing a laser engraving machine. The Hawk P2S CO2 cutter boasts a range of features that make it stand out in its category:

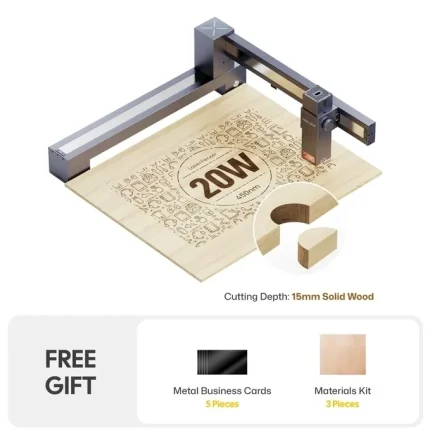

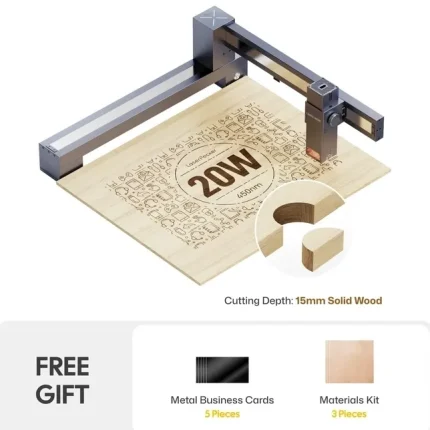

- Power Output: 40W continuous, ensuring efficient cutting and engraving on various materials.

- Laser Wavelength: 10.6µm CO2 laser, ideal for wood and other non-metallic materials.

- Engraving Speed: Up to 300 mm/s, providing fast processing times without compromising quality.

- Build Quality: Robust construction with durable components, ensuring long-term reliability.

- Software Compatibility: Works seamlessly with popular design software like CorelDRAW and Adobe Illustrator.

- Safety Features: Equipped with emergency stop buttons and automatic shut-off mechanisms for safe operation.

These specifications highlight the machine’s ability to handle a wide range of tasks efficiently.

Benefits of Using the Hawk P2S CO2 Laser Engraver

The Hawk P2S CO2 laser engraver offers several advantages that make it a valuable asset in woodworking and other industries:

Precision and Accuracy

One of the standout features of this machine is its ability to produce highly detailed engravings. Whether you’re working on intricate designs or simple patterns, the Hawk P2S ensures precision every time.

Versatility in Material Compatibility

The machine supports a variety of materials, including wood, acrylic, leather, and some plastics, making it a versatile tool for different projects.

Easy to Use

With intuitive controls and user-friendly software, even those new to laser engraving can operate the machine with ease.

Cost-Effective

Despite its high performance, the Hawk P2S is designed to be cost-effective in the long run, offering excellent value for money.

How to Choose the Right Laser Engraving Machine

Selecting the right laser engraving machine depends on several factors, including your project requirements and budget. Here are some considerations:

- Material Compatibility: Ensure the machine supports the materials you plan to work with.

- Power Output: Higher power output is necessary for thicker materials or industrial applications.

- Software Support: Check for compatibility with design software you already use.

- Build Quality: Invest in a machine with durable components for long-term reliability.

By evaluating these factors, you can make an informed decision that aligns with your needs.

Maintenance and Safety Tips

Proper maintenance is crucial to ensure the longevity and optimal performance of your laser engraving machine. Here are some tips:

- Regular Cleaning: Keep the machine clean to prevent dust buildup, which can affect performance.

- Lubrication: Follow the manufacturer’s guidelines for lubricating moving parts.

- Software Updates: Regularly update the software to access new features and improvements.

Safety should always be a priority when operating laser engraving machines. Always wear protective eyewear and follow the manufacturer’s safety guidelines to avoid accidents.

FAQ Section

1. What materials can the Hawk P2S CO2 laser engraver work with?

The Hawk P2S is compatible with various materials, including wood, acrylic, leather, and some plastics. It is particularly effective for wood laser engraving due to its high precision and power output.

2. Is the Hawk P2S suitable for industrial use?

Yes, the machine’s robust build quality and high performance make it ideal for both small-scale projects and large industrial applications.

3. How easy is it to set up the Hawk P2S laser engraver?

The setup process is straightforward, with user-friendly controls and intuitive software that simplifies operation.

4. What are the safety features of the Hawk P2S?

The machine includes emergency stop buttons, automatic shut-off mechanisms, and protective eyewear recommendations to ensure safe operation.

5. Can I use custom designs with the Hawk P2S?

Absolutely! The machine supports popular design software like CorelDRAW and Adobe Illustrator, allowing you to create and engrave custom designs effortlessly.

Conclusion

The Hawk P2S CO2 laser engraver is a powerful tool that combines precision, versatility, and ease of use. Whether you’re working on wood laser engraving or other materials, this machine delivers outstanding results. By understanding its technical specifications, benefits, and maintenance requirements, you can make the most of its capabilities in your projects.

For further information on laser engraving machines, check out our laser cutting guide or explore more resources on woodworking tools.

Miguel Dubois –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Operation and software are user-friendly. Fast speed boosts productivity. Well-built and reliable!

Carlos Martin –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise, the operation intuitive, and software user-friendly. Fast speeds boost efficiency. Solid build, highly reliable!

Jean Kim –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. The machine is intuitive to operate, software user-friendly. Fast engraving speeds boost productivity. Sturdy build, highly reliable.

Jean Garcia –

Absolutely fantastic laser engraver! The precision and quality of engravings are impeccable. The software is intuitive, and operations are seamless. Fast engraving speeds boost productivity. Sturdy build, highly reliable. 5 stars!

Mei Johnson –

This laser engraver delivers exceptional detail and precision, with intuitive software and smooth operation. It’s fast, efficient, and built to last, earning it a well-deserved 5 stars!

Roberto Rodriguez (verified owner) –

**Performance & User Experience Review**

The xTool F1’s 20W diode excels on wood (char-free engraving at 3000mm/min) and acrylic (clean vector cuts), but struggles with mirrored finishes, requiring masking. The hybrid 10W IR module handles stainless steel tags impressively. Setup was plug-and-play, though aligning the IR lens demanded precision. Software presets are beginner-friendly, but manual adjustments for mixed materials (e.g., leather/wood keychains) are tedious. The autofocus and passthrough slots saved hours on batch coaster projects. A built-in air assist would mitigate residue on deep engravings. Ideal for makers needing versatility without industrial pricing.

Camila Bruno (verified owner) –

This laser engraver excels in versatility, delivering sharp results on wood, acrylic, and leather. Its precision is impressive, with clean lines even on intricate designs like custom jewelry tags. The speed is adequate for small batches but could improve for larger projects. Setup was straightforward, and the software interface is intuitive, though a few advanced features require practice. I recommend it for artists and small-scale businesses seeking reliable performance at an affordable price.

Michelle Carter (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather with precision up to 1200 DPI. The learning curve is manageable, especially with intuitive software that simplifies project setup. While it lacks advanced safety features compared to competitors, its compact design and affordable price make it ideal for hobbyists and small-scale businesses. For long-term use, the machine proves cost-effective, offering consistent quality without frequent maintenance needs.

Deborah Brown (verified owner) –

The laser engraver excels in precision and versatility, handling wood, acrylic, and leather seamlessly. Its high power ensures clean cuts on thick materials, while its adjustable settings allow delicate detailing on thin acrylic. The user-friendly software interface simplifies project setup, though a steeper learning curve is needed for advanced features. Ideal for creative professionals, it supports both artistic and business applications, offering excellent value with consistent performance over time. A minor suggestion would be additional training resources to help users unlock its full potential.

Min-jun Koch (verified owner) –

The laser engraver excels in precision, delivering sharp results on wood, acrylic, and leather. For instance, intricate wedding invitations on 3mm birch plywood showcased its 1200 DPI capability. Setup was straightforward, but the learning curve for software customization is moderate. The drag-and-drop interface and preloaded templates save time. While it handles small to medium projects effectively, additional safety features would enhance user confidence. Overall, a solid choice for artistic and business use, offering good value with consistent performance.

Rafael Han (verified owner) –

**Specific Project Experience:**

As a DIY enthusiast, I recently utilized the laser engraver for creating detailed architectural models. The machine excelled in cutting through various materials like wood and acrylic with precision, achieving intricate designs that were challenging to replicate manually.

One notable challenge was managing material behavior—wood produced significant smoke, while acrylic emitted fumes requiring ventilation. To address this, I adjusted the power settings for each material, ensuring optimal results without compromising quality.

The laser engraver’s precision allowed me to achieve clean cuts and engravings, enhancing the model’s aesthetics. This experience highlighted the machine’s versatility and adaptability across different materials, making it an invaluable tool for architectural projects.

Anthony Chen (verified owner) –

This laser engraver is a game-changer! I used it to create intricate business logos on wood, and it cut with perfect precision every time. The speed was impressive—it made my projects so much easier and faster than traditional methods. Totally recommend if you’re looking for high-quality results without the hassle.

James Mueller –

五星好评: This laser engraver delivers exceptional precision and stunning results. The operation is smooth, software intuitive. High speed & efficiency. Solid build, reliable performance!