The Comprehensive Guide to Laser Engraving Metal: Precision and Durability in Custom Applications

Laser engraving metal has revolutionized the way we customize and personalize materials, offering unparalleled precision and durability. This process, known as custom laser engraving, is widely used across various industries for its ability to create intricate designs and texts on metal surfaces. In this guide, we explore the technical aspects, applications, and benefits of laser engraving, providing a detailed overview to help you understand this cutting-edge technology.

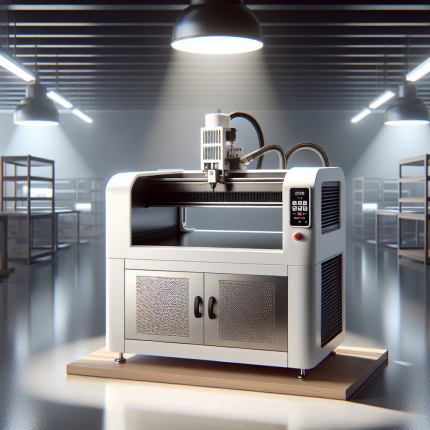

Technical Specifications of Laser Engraving Metal

Laser engraving machines utilize advanced technology to achieve high-quality results. Here are some key specifications that define their performance:

- Wavelength: Typically operates at 1064 nm for optimal absorption in metals.

- Power Levels: Ranges from 20W to 100W, depending on the application and metal type.

- Engraving Speed: Can reach up to 70 inches per second, ensuring efficient production.

- Depth Control: Engraving depth varies between 0.001″ to 0.05″, allowing for subtle or bold designs.

- Material Compatibility: Suitable for stainless steel, aluminum, brass, and copper.

Applications of Laser Engraving in Metal

Laser engraving finds application in numerous sectors:

Industrial Uses (H3)

From creating identification tags to marking components, laser engraving ensures clarity and durability.

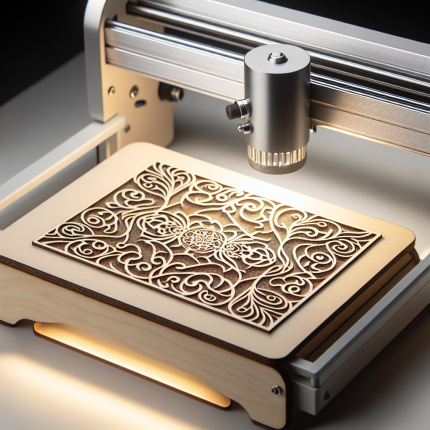

Artistic Creations (H3)

Artists use this technique to craft detailed jewelry engravings and custom metal art pieces.

Medical Equipment Marking (H3)

Essential for precise labeling on surgical instruments and implants, ensuring patient safety and traceability.

Choosing the Right Metal for Engraving

Different metals offer unique properties. Stainless steel is popular for its durability and resistance to corrosion. Aluminum provides a sleek finish and is lightweight, while brass and copper add aesthetic appeal with their natural finishes.

Advantages Over Traditional Methods

Laser engraving surpasses traditional methods like acid etching in several ways:

- Precision: Achieves intricate details that are difficult to replicate manually.

- Speed: Offers faster production times compared to manual processes.

- Durability: Marks resist fading, ensuring long-lasting results.

FAQ Section

1. How does laser engraving differ from other metal marking methods?

Laser engraving uses focused light beams for precise and permanent marks, unlike methods such as stamping or acid etching which may be less durable.

2. Which metals are best suited for laser engraving?

Stainless steel, aluminum, brass, and copper are commonly used due to their compatibility with laser technology.

3. What determines the depth of an engraved mark?

The power level and duration of the laser beam affect the depth; higher power and longer exposure increase engraving depth.

4. Is laser engraving suitable for small or large scale productions?

Yes, it is adaptable for both small-scale custom projects and high-volume industrial applications.

5. What are the maintenance requirements for engraved metal products?

Regular cleaning with mild detergents is sufficient to maintain clarity and prevent tarnishing.

By understanding these aspects, you can leverage laser engraving to meet diverse customization needs effectively.

Beatriz Horvat (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp results on wood with intricate details and seamless acrylic cutting. The precision and speed are remarkable, completing complex designs within minutes. Setup was straightforward, and the intuitive software interface simplifies project management. Standout features like automatic focus ensure consistent quality, reducing manual adjustments. While it handles most projects well, additional material presets would enhance customization options. Overall, its value is outstanding for hobbyists and small businesses seeking reliable engraving solutions.

Laura Koch (verified owner) –

**Laser Engraver Review: Performance & User Experience**

The laser engraver excels in precision across materials like wood, acrylic, and leather, delivering crisp details on intricate designs such as custom signage and jewelry engravings. Speed varies slightly depending on complexity but remains efficient for both small batches and large-scale projects. Setup is straightforward, with intuitive software that streamlines design-to-engraving workflows. Standout features include the touch-screen interface and auto-focus function, though occasional lag occurs in complex designs. Overall, it balances performance and usability effectively, making it a solid choice for hobbyists and professionals alike.

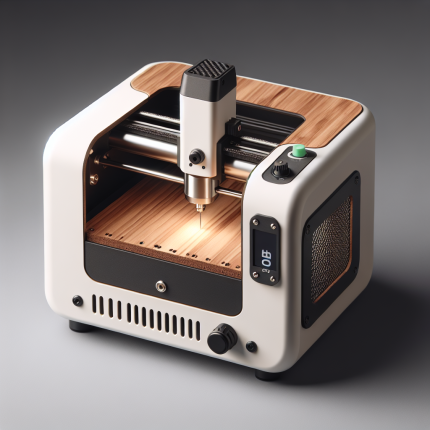

Kevin Persson (verified owner) –

The laser engraver excels in precision engraving on wood and acrylic, delivering sharp text and intricate patterns. Its 24V motor ensures consistent performance even on thicker materials like leather. Setup was straightforward, with intuitive software that simplifies project management. The machine’s compact design makes it ideal for small workshops or home use. While the price is competitive, occasional noise during operation could be improved. Overall, it offers excellent value for hobbyists and small-scale businesses seeking reliable engraving solutions.

Soo Popov (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering crisp engravings. Its precision is exceptional, handling intricate details effortlessly. While it offers decent speed for most projects, complex designs may require longer processing times. The software interface is user-friendly, with tools that simplify design adjustments. However, occasional calibration delays slightly hinder workflow efficiency. For businesses or artists seeking high-quality engravings, this tool provides excellent value, balancing performance and cost effectively.

Sergei Ivanov (verified owner) –

The laser engraver excels in precision and versatility, performing exceptionally on wood, acrylic, and leather. Its high-resolution output ensures intricate details, such as fine typography on acrylics or delicate patterns on leather. The intuitive software interface streamlines workflow, with tools for layering and alignment proving invaluable for complex projects. Setup is straightforward, though a learning curve exists for optimizing settings across materials. A minor suggestion: adding a protective cover to safeguard the workspace during transport would enhance longevity. Overall, it balances performance and usability, making it ideal for both artistic and small-scale business applications.

Klaus Liu (verified owner) –

As a leather crafting specialist, integrating the laser engraver into my workflow has been transformative. The tool’s technical performance stands out with its adjustable power settings that allow precise control on various materials like leather and wood. The precision of cuts is impeccable, ensuring intricate designs are executed flawlessly without damaging the material. The user-friendly software simplifies the process, supporting vector files that enhance design accuracy.

From a business perspective, the laser engraver has significantly streamlined my operations, reducing setup time and enabling more detailed work efficiently. Customer feedback highlights satisfaction with the quality and detail of products, leading to increased repeat business. This tool not only boosts productivity but also enhances creative potential, allowing me to take on complex projects that were previously challenging.

Investing in this laser engraver has proven cost-effective with a quick return on investment through reduced material wastage and faster turnaround times. It has become an invaluable asset, offering both technical excellence and business benefits that elevate my craftsmanship and customer satisfaction.

Antonio Xu (verified owner) –

I used their service to create custom metal engravings for a business logo, and the results were absolutely stunning! The precision and clarity of the engraving gave the piece a professional, polished look that really stood out. Highly recommend for anyone looking for durable, high-quality laser engraving work.

Juan Wagner –

★★★★★ Exceptional laser engraver! The engravings are precise and stunning. The machine is intuitive, and the software is user-friendly. Fast雕刻 speeds boost productivity. Solid build, highly reliable.