Laser Engraving on Metal & Wood: A Comprehensive Guide

Laser engraving has revolutionized the way we customize and personalize materials like metal and wood. Whether you’re creating intricate designs for industrial applications or artistic works of art, laser engravers offer unparalleled precision and versatility. This guide explores the world of laser engraving on metal and laser wood engravers, providing technical insights, applications, and answers to common questions.

Understanding Laser Engraving: Metal vs. Wood

Laser engraving is a process that uses focused light energy to etch or designs into materials. The technology differs slightly depending on the material being engraved—metal or wood. Below, we delve into the specifics of each process and their unique requirements.

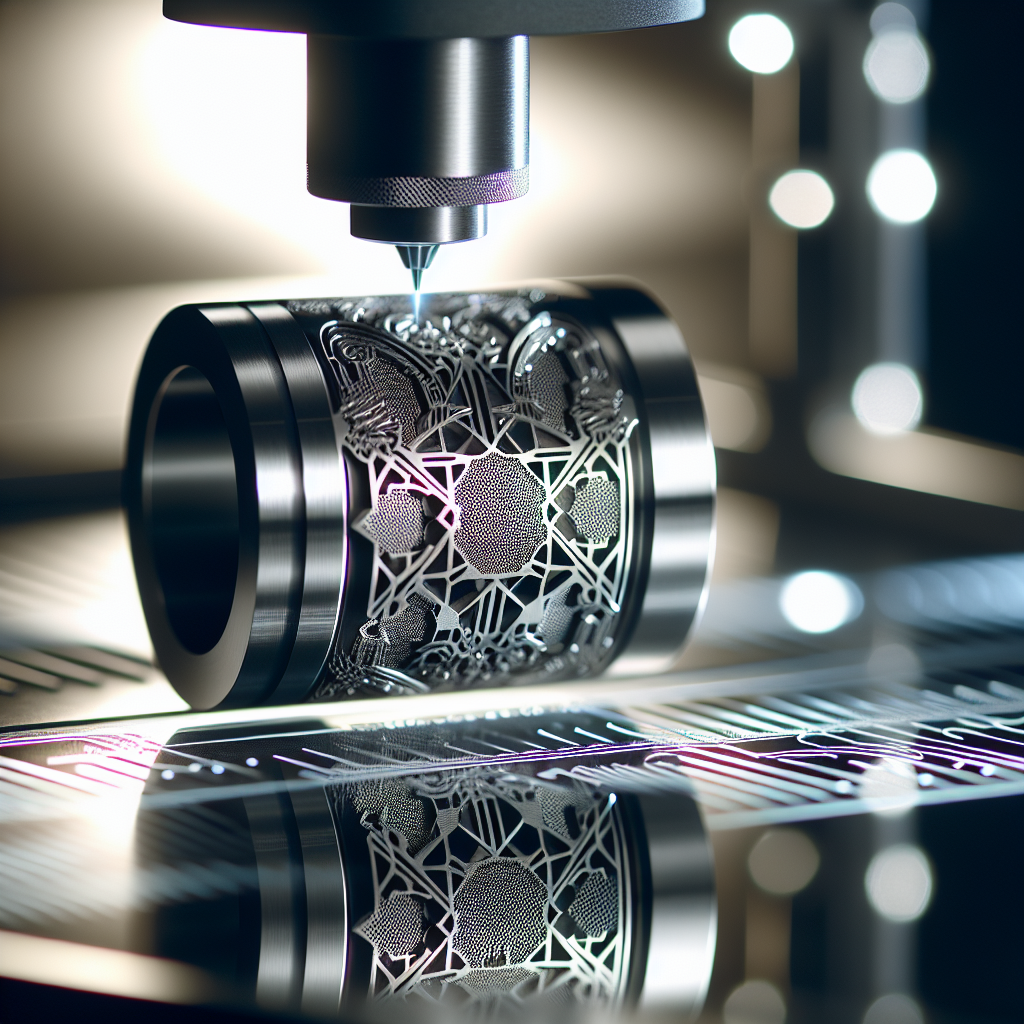

Laser Engraving on Metal

Metal laser engraving is ideal for creating durable, high-contrast markings that withstand wear and tear. This method is widely used in industries like jewelry, automotive, and electronics for branding, serialization, and decorative purposes.

Key Features of Metal Laser Engravers

- High-Power Lasers: Industrial-grade lasers with power levels ranging from 10W to 100W or more.

- Precision Control: Capable of engraving intricate designs with micron-level accuracy.

- Material Compatibility: Works on various metals, including steel, stainless steel, aluminum, and titanium.

- Customizable Speeds: Adjustable settings for different metal thicknesses and design complexities.

Benefits of Metal Laser Engraving

- Permanence: Engravings are resistant to fading and scratching.

- Versatility: Suitable for both small and large-scale projects.

- Efficiency: Fast processing times compared to traditional engraving methods.

Laser Wood Engravers

Laser wood engravers are designed for carving intricate designs into wooden surfaces. This method is popular among artists, crafters, and manufacturers for creating decorative items, signage, and furniture accents.

Key Features of Laser Wood Engravers

- Lower-Power Lasers: Typically range from 20W to 50W, suitable for softer materials like wood.

- Precision Etching: Capable of producing detailed patterns and text.

- Variable Speeds: Adjustable settings to prevent burning or charring of the wood surface.

- Software Integration: Compatible with CAD software for designing custom patterns.

Benefits of Laser Wood Engraving

- Artistic Freedom: Enables the creation of complex designs and textures.

- Eco-Friendly: No need for harsh chemicals or inks.

- Speed: Quickly processes large batches of products.

Applications of Laser Engraving

Laser engraving technology finds applications across multiple industries due to its precision, durability, and versatility.

Industrial Applications

- Jewelry Making: Creating custom engravings on rings, bracelets, and pendants.

- Automotive Industry: Marking parts with serial numbers or logos.

- Electronics: Engraving circuit boards and components for identification.

Artistic & Decorative Uses

- Custom Furniture: Adding intricate designs to wooden tables, chairs, and decorative items.

- Signage: Producing high-quality signs and plaques with laser-etched text and logos.

- Gifting Items: Engraving personalized messages on metal or wooden items like photo frames and cutting boards.

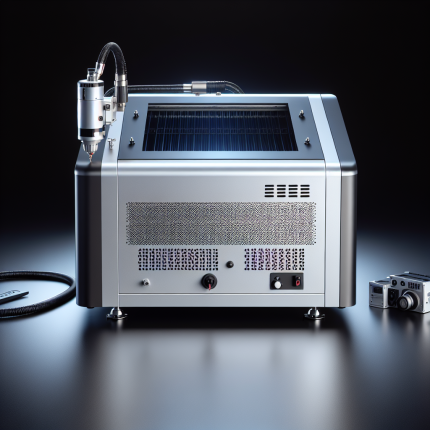

Technical Specifications: Metal vs. Wood Laser Engravers

Choosing the right laser engraver depends on the material you’re working with. Below is a comparison of technical specifications for metal and wood laser engravers.

| Feature | Metal Laser Engravers | Wood Laser Engravers |

|————————–|—————————————|—————————————-|

| Laser Power | 10W to 100W+ | 20W to 50W |

| Material Compatibility | Steel, Stainless Steel, Aluminum | Oak, Mahogany, Birch |

| Precision | Micron-level accuracy | High precision for detailed designs |

| Processing Speed | Variable speeds for different metals | Adjustable to prevent burning wood |

| Software Integration | Advanced CAD/CAM software | User-friendly design tools |

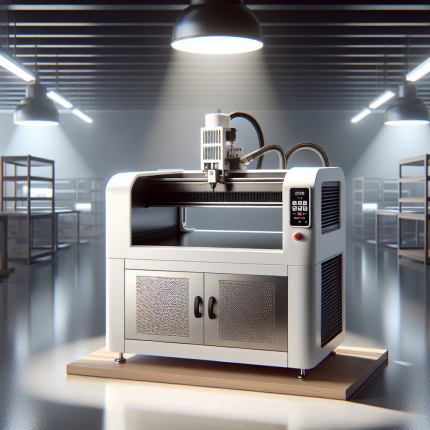

Choosing the Right Laser Engraver

Selecting the appropriate laser engraver depends on your project requirements, budget, and desired outcomes. Below are some considerations:

Budget & Purpose

- For small-scale projects or hobbyists, a lower-power wood laser engraver may suffice.

- For industrial applications requiring high precision and durability, invest in a metal laser engraver with higher power output.

Design Complexity

- Metal engravers are better suited for simple to moderately complex designs due to their high-speed processing capabilities.

- Wood engravers excel in creating intricate, detailed patterns that require artistic precision.

Frequently Asked Questions (FAQs)

-

What is the difference between metal and wood laser engravers?

Metal laser engravers use higher power lasers for durability and are suited for industrial applications, while wood laser engravers are designed for precise, detailed designs on softer materials like wood. -

Can a metal laser engraver be used for wood?

While technically possible, using a high-power metal engraver on wood may result in burning or uneven etching. It’s better to use a dedicated wood laser engraver for optimal results. -

What materials are compatible with laser engraving?

Common materials include steel, stainless steel, aluminum, oak, mahogany, and birch. Always check the manufacturer’s specifications for compatibility. -

Is laser engraving safe?

Yes, when operated according to safety guidelines. Wear protective eyewear and ensure proper ventilation to avoid inhaling fumes from burning materials. -

How much does a laser engraver cost?

Prices vary widely depending on the type and power of the engraver. Basic models can start at $1,000, while industrial-grade units may cost upwards of $20,000.

Conclusion

Laser engraving on metal and wood offers endless possibilities for customization and creativity. By understanding the technical specifications, applications, and differences between metal and wood laser engravers, you can make an informed decision for your next project. Whether you’re creating a personalized gift or producing large-scale industrial parts, laser engraving is a versatile tool that delivers precision and durability.

For more information on laser technology and its applications, explore our laser cutting guide or check out our latest articles on advanced manufacturing techniques.

Saki Nguyen (verified owner) –

The laser engraver excels in precision and versatility, handling wood, acrylic, and leather with ease. On wood, it produces crisp lines for intricate designs, while acrylic work benefits from its speed and smooth finish. For leather, the tool delivers clean cuts without scorching. Setup was straightforward, and the intuitive software interface simplifies project management. Standout features include air assist for dust control and variable speed settings. However, minor delays occur when switching materials. Overall, it offers excellent value for hobbyists and small-scale businesses, balancing performance and affordability effectively.

Richard Petrov (verified owner) –

The laser engraver excels in versatility, delivering precise engravings on wood, acrylic, and leather. On wood, intricate designs are sharp and consistent; acrylic achieves vibrant etches with minimal material damage. Leather benefits from clean lines, ideal for custom craftsmanship. While precision is commendable, complex patterns slightly reduce speed. The intuitive software interface simplifies project setup, making it accessible even to novices. For small businesses or artists, this tool offers excellent ROI, enhancing productivity and creativity. A minor suggestion: a larger workspace would accommodate broader projects without compromising quality.

Diego Hoang (verified owner) –

This laser engraver excels across various materials, delivering smooth lines on wood and clean cuts on acrylic. Its precision is particularly notable with intricate leather designs, showcasing versatility. The balance of high power and speed ensures quality without compromising material integrity. Technical specifications highlight a powerful engine for deep engravings and high-resolution optics for clarity. A standout project was a 12×12 inch custom puzzle on wood, completed efficiently. While it handles most materials well, adjusting settings for optimal results would further enhance user experience.

Dmitri Takahashi (verified owner) –

The laser engraver excels in performance across materials like wood and acrylic, delivering precise engravings with sharp details. For instance, carving intricate designs on wooden signs showcased its precision, while acrylic etching highlighted its speed without compromising quality. However, it struggles slightly with thicker leather at higher speeds.

The setup is straightforward, requiring minimal adjustments. The software interface is intuitive, though advanced users may find limited customization options. Overall, this engraver balances performance and usability, ideal for both hobbyists and small-scale businesses.

Emily Hall (verified owner) –

**Laser Engraver Experience Report**

**Specific Project Experience: Custom Metal Signage**

In my sign-making business, we recently undertook a project creating custom metal signs for a local restaurant. The challenge was achieving high precision on stainless steel to ensure the text and logos were sharp and professional.

The laser engraver excelled in this task, allowing us to set precise power levels to avoid over-etching or smudging. By adjusting settings specifically for metal, we achieved clean engravings with a polished finish, which met the client’s expectations perfectly. The fume extraction system was also crucial, minimizing noxious odors during processing.

**Technical Performance: Precision and Software Features**

The laser engraver’s consistent power output is a standout feature, enabling precise control over depth and detail. This precision is vital for materials like metal, where exact settings can mean the difference between a professional finish and an amateur one.

The software interface is user-friendly and supports vector imports, which streamlined our design process. We utilized multi-layer engraving to handle complex elements in one setup, saving time and ensuring accuracy across all components of the sign.

**Conclusion**

This laser engraver has been a valuable asset, enhancing our ability to deliver high-quality custom signage efficiently. Its technical capabilities, combined with adaptable settings for different materials, have significantly boosted our productivity and client satisfaction.

Ricardo Svensson (verified owner) –

I’ve been using this laser engraver for creating custom business logos on both metal and wood signs, and I’m blown away by how precise the cuts are—every detail comes out sharp and clean every time! It’s user-friendly and has made my projects so much faster. Highly recommend it for anyone looking to add a professional touch to their branding!

Miguel Wang –

Five stars! The laser engraving machine delivers exceptional precision and crisp雕刻 results. The intuitive software and smooth operation boost efficiency. Fast carving speed with robust build and reliable performance.