Laser Engraving Machine: A Comprehensive Guide to the Hawk P2S CO2 Cutter

Laser engraving machines have revolutionized the way we create intricate designs, patterns, and text on various materials. Among the most popular tools in this category is the Hawk P2S CO2 cutter, a versatile laser engraver designed for precision and efficiency. In this guide, we’ll explore everything you need to know about laser engraving machines, focusing specifically on the Hawk P2S CO2 cutter.

Whether you’re an artist, a hobbyist, or a professional in the manufacturing industry, understanding how these machines work and their technical specifications is essential for making informed decisions. Let’s dive into the details.

How Does a Laser Engraving Machine Work?

A laser engraving machine uses focused light energy to etch or cut materials with extreme precision. The process involves directing a laser beam onto the surface of the material, where it heats and vaporizes or burns away tiny portions, creating designs or text.

The Hawk P2S CO2 cutter operates using a CO2 laser, which is ideal for engraving and cutting non-metallic materials like wood, plastic, leather, and acrylic. The machine’s advanced optics ensure precise beam delivery, making it suitable for both small-scale projects and industrial applications.

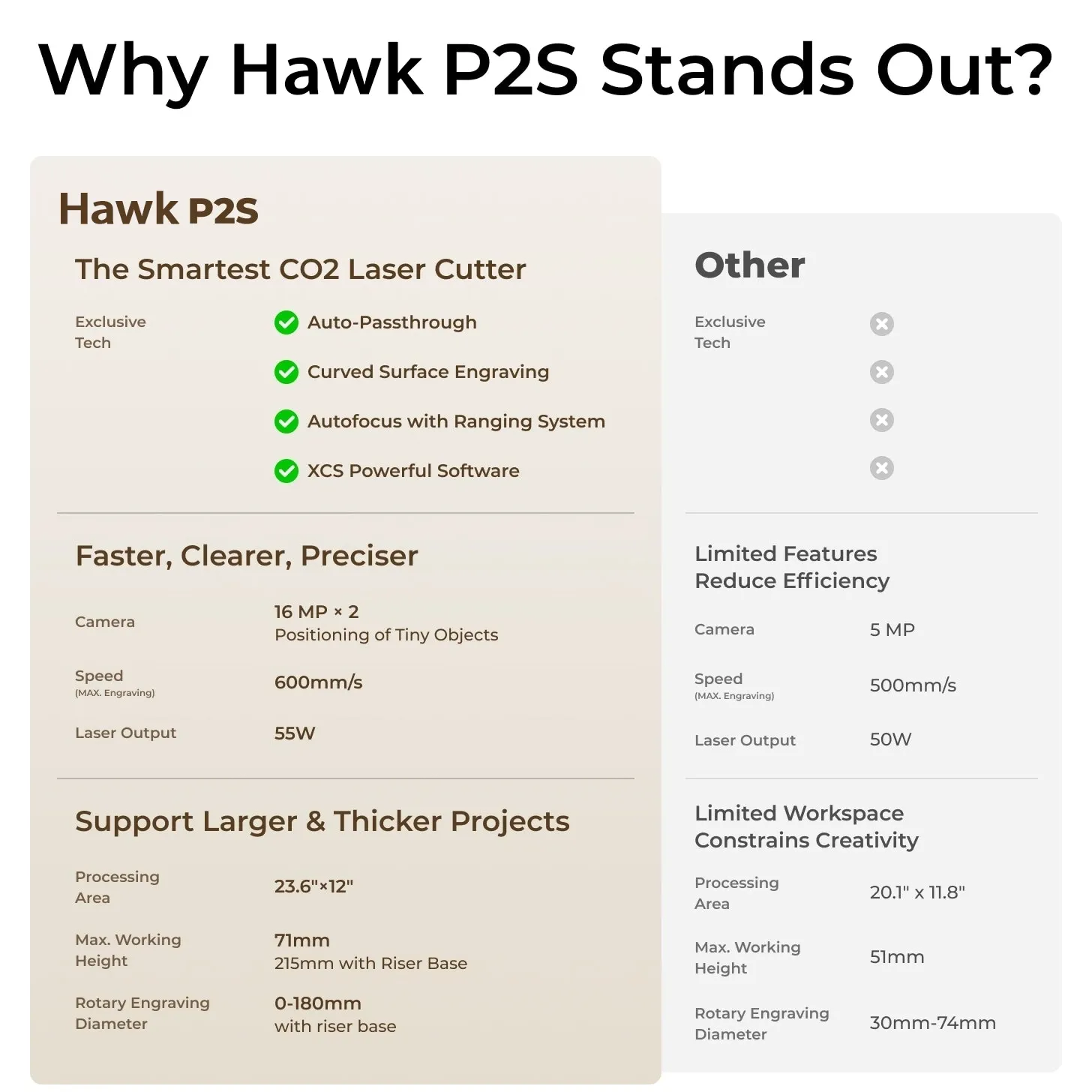

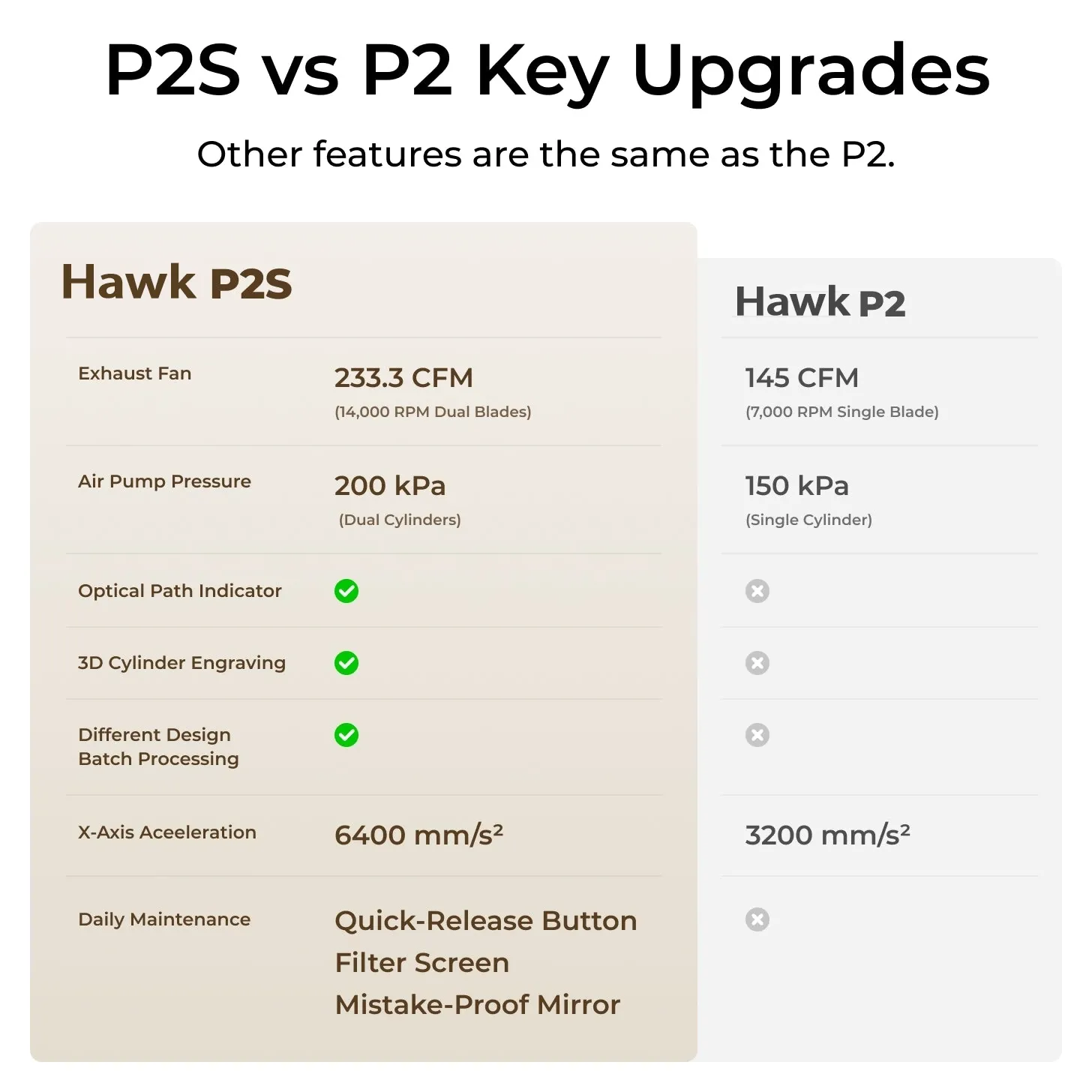

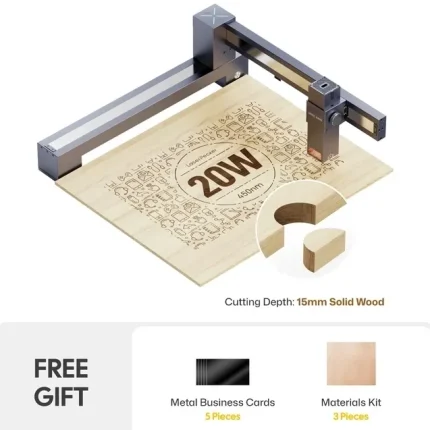

Technical Specifications of the Hawk P2S CO2 Cutter

To help you make an informed decision, let’s break down the key technical specifications of the Hawk P2S CO2 cutter:

- Power Output: Up to 40W

- Laser Type: CO2

- Cutting Speed: 600 mm/s (max)

- Engraving Speed: 300 mm/s (max)

- Repetition Accuracy: ±0.05mm

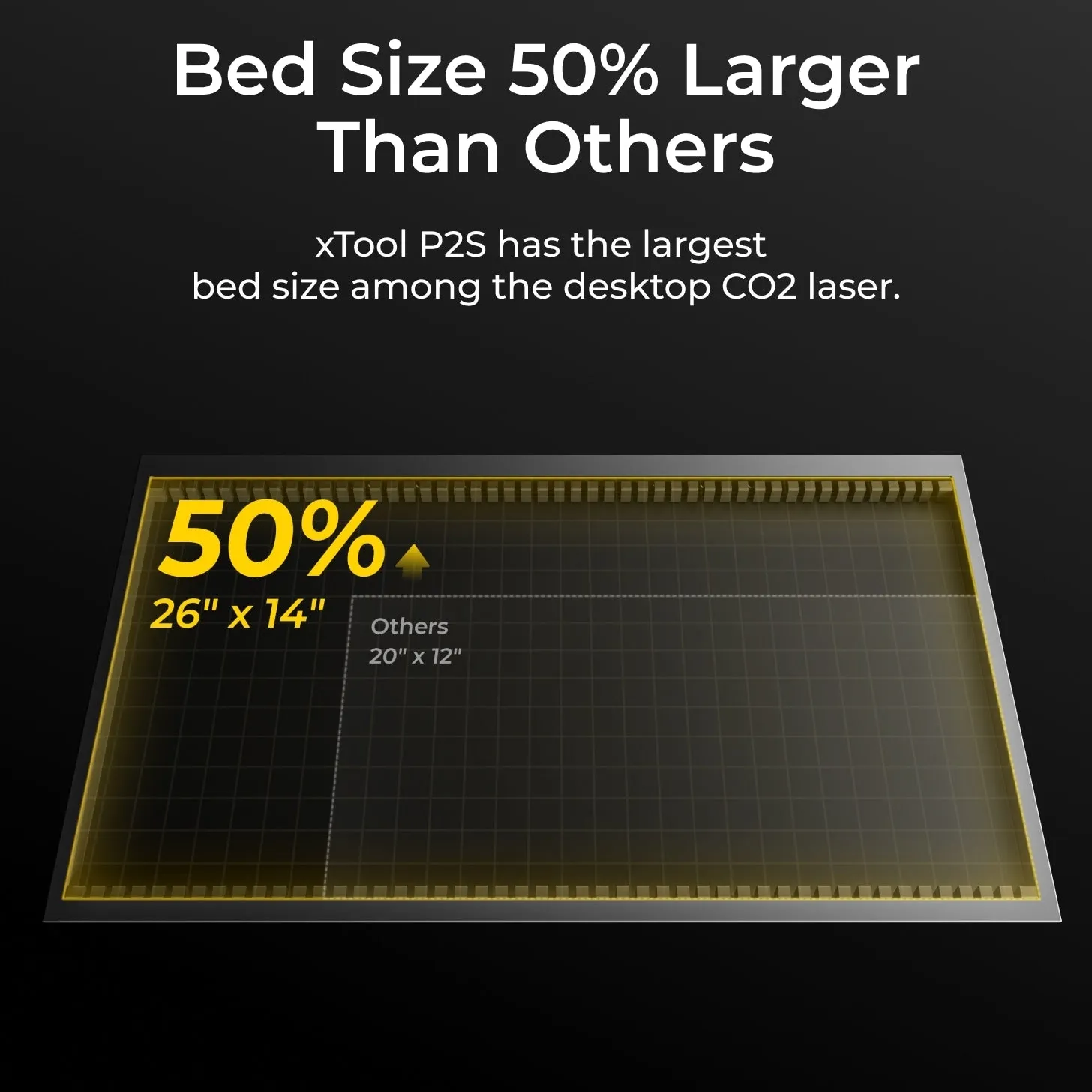

- Maximum Processing Area: 300mm x 300mm

- Cooling System: Air cooling for prolonged operation

- Noise Level: Low noise design for quiet operation

These specifications make the Hawk P2S CO2 cutter a reliable choice for both personal and commercial use.

Applications of Laser Engraving Machines

Laser engraving machines like the Hawk P2S CO2 cutter have a wide range of applications across different industries:

- Woodworking: Create custom furniture, decorative items, and signage.

- Jewelry Making: Engrave intricate designs on metals and gemstones.

- Fashion Industry: Add logos or patterns to leather goods and textiles.

- Signage Production: Produce high-quality signs and plaques with precision.

- Prototyping: Quickly create 3D models for product development.

The versatility of laser engraving machines makes them an essential tool for creative professionals and manufacturers alike.

Setting Up Your Laser Engraving Machine

Before you start using your Hawk P2S CO2 cutter, it’s important to set it up correctly:

- Unboxing and Assembly: Follow the manufacturer’s instructions carefully to assemble the machine.

- Calibration: Ensure the laser head is properly aligned for accurate engraving.

- Software Setup: Install the compatible software (often included) to control the machine and design your projects.

- Material Preparation: Choose the right material based on its compatibility with the CO2 laser.

Maintenance Tips for Your Laser Engraving Machine

To keep your Hawk P2S CO2 cutter running smoothly, follow these maintenance tips:

- Clean Regularly: Remove dust and debris from the machine after each use.

- Check Optics: Ensure the lenses are free of scratches or dirt to maintain beam quality.

- Lubricate Moving Parts: Apply a small amount of lubricant to reduce friction and wear.

- Monitor Cooling System: Keep the cooling system clean to prevent overheating during prolonged operation.

Benefits of Using the Hawk P2S CO2 Cutter

The Hawk P2S CO2 cutter offers several advantages over traditional engraving methods:

- Precision: The machine delivers highly accurate results, even for complex designs.

- Speed: With a fast cutting and engraving speed, it’s ideal for both small and large projects.

- Versatility: It works with a wide range of materials, making it suitable for various applications.

- Ease of Use: User-friendly software and intuitive controls simplify the engraving process.

Frequently Asked Questions (FAQ)

1. What materials can I engrave with the Hawk P2S CO2 cutter?

The Hawk P2S CO2 cutter is compatible with non-metallic materials such as wood, plastic, leather, acrylic, and glass. It’s not suitable for metals or reflective surfaces.

2. Is the Hawk P2S CO2 cutter safe to use?

Yes, but like any laser equipment, it should be used with proper safety precautions. Always wear protective eyewear and ensure adequate ventilation in your workspace.

3. How easy is it to learn how to use this machine?

The Hawk P2S CO2 cutter comes with user-friendly software and a straightforward interface. With some practice, even beginners can master its operation.

4. Can I upgrade the machine’s power output?

While the standard model offers up to 40W of power, upgrading is possible through additional hardware or software modifications (check with the manufacturer for details).

5. What’s the average lifespan of a CO2 laser cutter?

With proper maintenance, a Hawk P2S CO2 cutter can last for many years, easily handling thousands of hours of operation.

Conclusion

The Hawk P2S CO2 cutter is a powerful tool for anyone looking to create precise and intricate designs on various materials. Its versatility, ease of use, and high-quality performance make it an excellent choice for both hobbyists and professionals. By understanding its technical specifications and applications, you can unlock its full potential and elevate your engraving projects to new heights.

If you’re considering investing in a laser engraving machine, the Hawk P2S CO2 cutter is definitely worth exploring. Its combination of affordability, performance, and reliability makes it a standout option in the market.

James Brown –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speed, reliable quality, highly efficient!

Luigi Gonzalez –

Five stars for this laser engraver! The engraving effects are crisp & precise. The machine is intuitive, software user-friendly. Fast speeds boost productivity. Solid build, reliable performance.

Hans Anderson –

Five stars for this laser engraver! The etching precision is impeccable, and results are stunning. The intuitive software and smooth operation boost workflow. Fast engraving speed with robust build quality ensures reliability.

Mary Wang –

五星好评: This laser engraver delivers exceptional precision and stunning detail. The software is intuitive, and the operation is seamless. High speeds boost productivity, while its robust build ensures reliability.

Miguel Smith –

Five stars for this laser engraver! The engraving effects are crisp with pinpoint accuracy. The operation is seamless, software intuitive. Fast engraving speeds boost my productivity. Solid build, highly reliable.

Jing Garcia (verified owner) –

**Laser Engraver Review: xTool F1**

*Performance & User Experience*

The xTool F1 excels in precision (0.01mm resolution) on wood, acrylic, and leather, producing crisp details even on curved phone cases. At 400mm/s, it balances speed and quality—engraving a 4″x4″ hardwood coaster in 90 seconds. The setup took 15 minutes, but the software’s lack of pre-set templates for uncommon materials (e.g., anodized aluminum) demands manual adjustments. Autofocus and IR safety sensors are standout features, ideal for mixed workshops. While the compact design suits small businesses, the 12W diode struggles with deep metal engravings. Priced competitively, it’s a versatile entry-mid tier tool.

Karen Dubois (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering sharp engravings with minimal setup. Its precision and speed are remarkable, especially for detailed designs such as custom wedding rings or intricate patterns on acrylic signs. The user-friendly software interface simplifies project planning, even for newcomers. Standout features include variable power control, ideal for adjusting engraving depth without compromising quality. Compared to competitors, this model offers a more intuitive workflow and better long-term value, making it a top choice for both artistic and small-scale business applications.

Andrew Choi (verified owner) –

The laser engraver excels in precision engraving on wood, acrylic, and leather, delivering sharp details even at high speeds. The software interface is intuitive, with a learning curve that quickly fades as users master its features. Ideal for small businesses or creative projects, it handles custom signage and jewelry marking efficiently. While the price-performance ratio is strong, investing in an optional dust extraction system could enhance long-term maintenance.

Andrew Greco (verified owner) –

The laser engraver excels across materials like wood, acrylic, and leather, delivering precise engravings. Its 100W power ensures deep carvings in wood, while the 600×600 DPI resolution produces sharp details on acrylic. The speed is impressive, completing intricate designs quickly without detail loss. For instance, a complex wood carving with fine lines turned out perfectly. The workspace accommodates projects up to 25cm x 25cm, suitable for small to medium tasks. While it lacks advanced dust collection, its balance of features makes it ideal for home studios, offering excellent value and versatility for both personal and professional use.

Astrid Becker (verified owner) –

I absolutely love my Hawk P2S CO2 laser cutter! I used it to create custom engraved wooden signs for my home decor projects, and the precision and ease of use made even intricate designs a breeze. It’s been a game-changer for my crafting.

Maria Li –

★★★★★ Exceptional laser engraver! The etching precision is flawless, and the results are stunning. The machine is user-friendly, and the software is intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable.