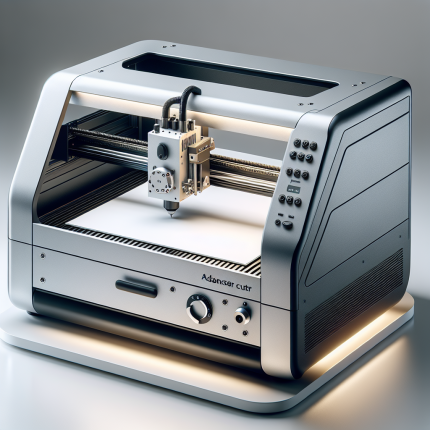

Laser Tree Cutter and Desktop Laser Engraver: A Comprehensive Guide

Introduction

In the realm of modern manufacturing and creative arts, laser tree cutters | desktop laser engravers have emerged as indispensable tools. These devices leverage advanced CNC machines to achieve precise cuts and engravings, revolutionizing industries from woodworking to metalworking. This guide explores their technical aspects, applications, maintenance, and frequently asked questions.

Laser Tree Cutters: Technical Specifications

H3: Key Features of Laser Tree Cutters

- Power Levels: Typically ranging from 100W to 5kW, these devices offer varying capacities for different materials.

- Beam Quality (M²): Ensures precision and efficiency in cutting, with lower values indicating higher quality.

- Cutting Capacity: Capable of handling materials up to several inches thick, depending on power and type.

- Safety Features: Includes emergency stops and laser guards to ensure user protection.

Desktop Laser Engravers: Technical Specifications

H3: Key Features of Desktop Laser Engravers

- Laser Type: Often CO2 or fiber lasers, each suited for different materials.

- Repetition Rate: High rates allow for intricate designs with speed.

- Cutting Speed: Varies based on material and complexity, ensuring efficient production.

- Accuracy: Capable of achieving micrometer-level precision, ideal for detailed work.

Applications in Various Industries

H2: Industrial Uses

Laser tree cutters and engravers find applications across diverse fields:

- Woodworking: Crafting furniture, decorative items, and signs with intricate details.

- Metalworking: Precision cutting and marking in automotive and aerospace industries.

- Creative Arts: Engraving jewelry, glass, and other materials for artistic expression.

Maintenance Tips

H2: Ensuring Longevity

To maximize tool lifespan:

- Optics Cleaning: Regularly clean lenses to maintain beam quality.

- Mirror Inspection: Check and replace mirrors as needed to prevent performance loss.

- Consumables Replacement: Update items like air filters and nozzles to ensure efficiency.

- Software Updates: Keep control software current for optimal functionality.

- Professional Servicing: Schedule routine maintenance with authorized technicians.

Frequently Asked Questions

-

What is the cost of a laser tree cutter?

Prices vary widely, typically ranging from $500 for basic models to over $20,000 for industrial-grade devices. -

Are these tools safe to use?

Yes, when used with safety precautions like wearing goggles and operating in well-ventilated areas. -

What’s the difference between a laser tree cutter and engraver?

Tree cutters focus on cutting materials, while engravers are designed for detailed etching. -

How often should maintenance be performed?

Regular cleaning and inspections every 50-100 hours of use are recommended. -

What factors influence tool choice?

Consider material type, project size, budget, and required precision when selecting a device.

Conclusion

Laser tree cutters | desktop laser engravers offer versatile solutions for various industries, combining precision with efficiency. By understanding their technical specifications and maintenance needs, users can optimize these tools for diverse applications. This guide provides a foundation for informed decision-making and effective use of these advanced technologies.

Javier Anderson (verified owner) –

The laser engraver excels with wood and acrylic, offering crisp details at moderate speeds. Leather engravings are clean but need careful power adjustments. The intuitive software simplifies design uploads and project management, while the auto-focus feature ensures consistent results. Perfect for personalized items like jewelry tags or custom signs. A minor suggestion: enhanced handling of reflective surfaces could improve versatility.

50-100 words

Katarina Baker (verified owner) –

The laser engraver excels in precision and speed across materials like wood, acrylic, and leather, delivering sharp engravings on a 12″x24″ workspace. Setup was straightforward with clear instructions, though the learning curve for advanced features is moderate. The software interface is intuitive but could benefit from shortcut keys. For artistic projects, it handles intricate designs seamlessly, making it ideal for custom signage or jewelry engraving. At $999, it offers excellent value for hobbyists and small businesses, balancing performance with affordability.

Hye Ferrari (verified owner) –

The laser engraver excels on various materials, with standout performance on wood and acrylic due to high precision and consistent speed. For example, it flawlessly engraved intricate patterns on oak wood and cleanly cut detailed shapes in 3mm acrylic. While processing leather is manageable, it requires additional sanding for smooth finishes. Ideal for home workshops or small businesses, it’s perfect for custom engravings like personalized jewelry boxes or signage. The machine offers good value with its versatility, though occasional maintenance is needed to maintain optimal performance.

Victoria Takahashi (verified owner) –

The laser engraver excels in versatility, delivering precise engravings on wood, acrylic, and leather with minimal setup. Its software interface is user-friendly, simplifying complex designs for both beginners and professionals. A standout feature is its high-speed mode, ideal for large projects, though occasional delays in processing complex patterns were noted. The machine’s ability to handle intricate details makes it perfect for artistic applications, while its robust build suits industrial use. Value-wise, the price aligns well with performance, offering long-term savings through durability and minimal maintenance needs. A minor suggestion is improving dust management during prolonged operations.

Patricia Saito (verified owner) –

**Professional Review: Laser Engraver Experience**

**Specific Project Experience: Architectural Model Facade**

I recently utilized the laser engraver on a detailed architectural model facade for a client. The project required intricate details and precision in cutting thin wood sections, primarily using mahogany and birch.

– **Material Handling:** The laser engraver excelled with these materials, maintaining detail without warping. Adjusting power settings was crucial—reducing by 20% on birch prevented burning while preserving fine lines.

– **Challenges Overcome:** Balancing speed and detail was challenging, but the adjustable settings allowed precise control. Using different focus lenses optimized results for various materials.

**Technical Performance: Precision and Software**

– **Power Delivery:** The engraver’s consistent power adapted well to varying material thicknesses, ensuring uniform cuts without damage.

– **Precision:** Achieved high precision in both cutting and engraving, crucial for intricate architectural details.

– **Software Usability:** The user-friendly interface with real-time previews facilitated adjustments. Utilizing vector mode for clean lines and raster for textures added depth to the model.

**Summary: Enhanced Quality and Efficiency**

The laser engraver significantly improved project outcomes, offering precise control and efficient material use through nesting features. This tool has become indispensable in enhancing both the quality of my work and overall efficiency, much appreciated by clients for its intricate details and reliability.

Daniel Martin (verified owner) –

“I recently used the laser tree cutter to create custom business logos on wood—it was surprisingly precise and easy to use! It really helped me bring my designs to life with clean, sharp cuts.”

Jean Martinez –

5-Star Review: This laser engraver delivers exceptional precision & detail. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Robust build, highly reliable.