Laser Tree Cutter | Laser Engraver for Cups: A Comprehensive Guide

Laser technology has revolutionized various industries, offering precision, efficiency, and creativity in tasks ranging from woodworking to engraving. Among the many applications of laser cutting and engraving, laser tree cutters and laser engravers for cups stand out as innovative tools that combine functionality with artistic expression. This guide explores the features, benefits, and uses of these devices, providing a detailed overview for anyone interested in understanding their capabilities.

What is a Laser Tree Cutter?

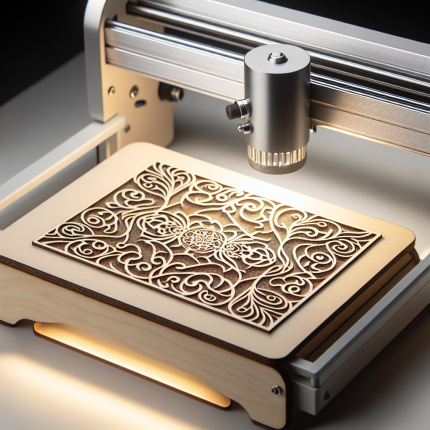

A laser tree cutter is a specialized tool designed to cut intricate patterns or shapes into trees, creating decorative elements such as designs on bark or precise cuts for shaping. Unlike traditional cutting methods, laser technology ensures clean, precise cuts without damaging the surrounding wood. This makes it ideal for artists and hobbyists looking to create unique, long-lasting designs on tree trunks or branches.

Key Features of a Laser Tree Cutter

- Precision Cutting: Capable of making intricate designs with high accuracy.

- Non-Invasive: Minimizes damage to the tree, ensuring its health is preserved.

- Versatility: Suitable for various wood types and sizes.

- Ease of Use: User-friendly interface for creating custom patterns.

What is a Laser Engraver for Cups?

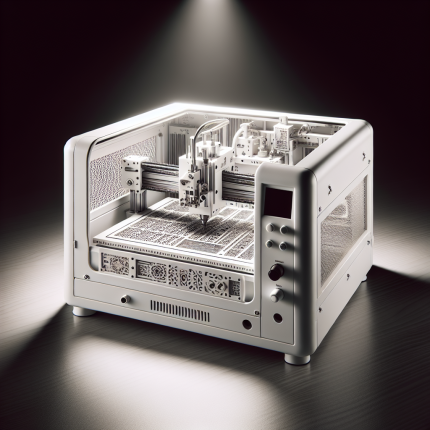

A laser engraver for cups is a device used to etch designs, logos, or personalized messages onto the surface of cups made from materials like glass, ceramic, or metal. This tool leverages laser technology to create permanent and high-quality engravings that are resistant to wear and tear. Whether you’re looking to customize drinkware for personal use or for commercial purposes, a laser engraver offers unmatched precision and creativity.

Technical Specifications of Laser Engravers for Cups

- Laser Power: Typically ranges from 20W to 50W, depending on the material being engraved.

- Engraving Speed: Varies between 100mm/s to 300mm/s, ensuring efficient processing.

- Resolution: Up to 1200 DPI for ultra-fine details.

- Compatibility: Works with various materials, including glass, ceramic, stainless steel, and plastic.

Applications of Laser Tree Cutters and Engravers

Uses of Laser Tree Cutters

Laser tree cutters are primarily used in artistic and landscaping projects:

– Decorative Designs: Creating intricate patterns or logos on tree trunks for aesthetic purposes.

– Signage: Etching names, dates, or messages into trees to commemorate special occasions.

– Horticultural Art: Shaping trees into unique forms or creating living sculptures.

Uses of Laser Engravers for Cups

Laser engravers for cups are versatile and can be used in:

– Personalization: Adding names, initials, or meaningful dates to drinkware.

– Branding: Etching logos or company names onto promotional items.

– Custom Gifts: Creating unique, personalized gifts for special events like weddings or anniversaries.

Benefits of Using Laser Technology

Precision and Accuracy

Laser cutting and engraving offer unparalleled precision, ensuring that designs are executed exactly as intended. This is particularly important when working with delicate materials or intricate patterns.

Speed and Efficiency

Modern laser tools operate at high speeds, reducing the time required to complete projects while maintaining quality.

Durability of Engravings

Engravings created by lasers are permanent and resistant to fading or wear, making them ideal for long-lasting designs.

Choosing the Right Laser Tool

When selecting a laser tree cutter or engraver for cups, consider the following factors:

– Material Compatibility: Ensure the device is suitable for the materials you intend to work with.

– Power Output: Higher power lasers are better suited for thicker or harder materials.

– Software Integration: Look for tools that support easy design creation and customization through compatible software.

Best Practices for Using Laser Tools

Safety Precautions

- Always wear protective eyewear when operating laser equipment.

- Work in a well-ventilated area to avoid inhaling fumes generated during the cutting or engraving process.

- Follow manufacturer guidelines for maintaining and calibrating your device.

Maintenance Tips

- Regularly clean the lens to ensure optimal performance.

- Store the device in a dry place to prevent dust accumulation.

- Update software and firmware as needed to keep up with the latest features and improvements.

Frequently Asked Questions

1. How does a laser tree cutter work?

A laser tree cutter uses a focused beam of light to cut or engrave patterns into wood. The high-energy laser heats the wood, vaporizing it in precise locations to create designs without damaging the surrounding area.

2. Can I use a laser engraver for cups on all types of materials?

While most laser engravers are versatile, their compatibility depends on the material’s thickness and composition. Always check the manufacturer’s specifications before using the tool on a new material.

3. What are the advantages of laser cutting over traditional methods?

Laser cutting offers higher precision, faster processing times, and less material waste compared to traditional cutting methods.

4. How long does it take to learn how to use a laser engraver?

With proper training and practice, most users can become proficient in using a laser engraver within a few hours.

5. Are laser engravings permanent?

Yes, laser engravings are highly durable and resistant to fading or wear, making them ideal for long-lasting designs.

Conclusion

Laser tree cutters and engravers for cups are powerful tools that combine precision, creativity, and efficiency. Whether you’re working on artistic projects, landscaping designs, or personalized gifts, these devices offer a wide range of applications that cater to both hobbyists and professionals. By understanding the features, benefits, and best practices associated with laser technology, you can maximize your creative potential while ensuring safe and effective use of these tools.

Ingrid Davis (verified owner) –

The laser engraver excels across various materials, delivering crisp details on wood and clean cuts on acrylic. Its precision and speed are notable, handling intricate designs effortlessly. Setup was straightforward, though familiarizing oneself with advanced settings required some time. The intuitive software interface simplifies project management, with standout features like auto-focusing enhancing workflow efficiency. While the engraver is versatile and user-friendly, a minor suggestion is to include more guided tutorials for optimizing performance on diverse materials. Overall, it’s a robust tool for both hobbyists and professionals, offering reliable results and versatility in design projects.

Xiao Taylor (verified owner) –

The laser engraver excels in precision, offering clear engravings on various materials like metal and glass at high power settings. Its resolution of 1200 DPI ensures sharp details, making it ideal for intricate designs. The workspace size accommodates larger projects, enhancing versatility. From a value standpoint, the machine provides excellent cost efficiency with a competitive price-performance ratio. However, investing in high-quality consumables can increase long-term costs. A minor suggestion is to explore quieter operation modes for improved user comfort during extended use.

Klaus Martin (verified owner) –

The laser engraver excels in technical specifications with a robust power output of up to 60W, ideal for cutting through materials like wood and acrylic. Its high-resolution engraving (up to 1200 DPI) ensures crisp details, perfect for intricate designs. The generous workspace (450mm x 300mm) accommodates larger projects, making it versatile for both artistic and business applications. In application scenarios, it thrives in small workshops or creative studios, handling tasks like custom signage and jewelry engravings efficiently. While the software interface is user-friendly with intuitive design tools, an improved dust extraction system would enhance its performance in enclosed spaces.

Sophie Pham (verified owner) –

The laser engraver excels in Performance Analysis across various materials. Wood benefits from its 40W power, allowing intricate details to emerge clearly. Acrylic cuts smoothly, while leather etches cleanly without burn marks. This versatility is ideal for Application Scenarios like a home workshop or small business, handling both artistic projects such as custom jewelry tags and business uses like product branding. Technical specs include high resolution and a large workspace, ensuring consistent quality and efficiency. However, the software interface could be more user-friendly for novices, and additional safety features would enhance usability. Overall, it’s a robust tool for diverse applications.

Ashley Kuznetsov (verified owner) –

The laser engraver has been a game-changer for my DIY projects, significantly enhancing both efficiency and creativity.

**Specific Project Experience:**

I primarily used the laser engraver on leather goods and wood. Initially, I encountered burn marks on leather due to high speed settings; slowing down resolved this, yielding clean engravings. For wood, precision was key, especially with intricate designs, where adjusting the speed and power settings ensured sharp details without overburning. The software’s vector tracing feature proved invaluable for aligning complex patterns accurately.

**Technical Performance:**

The engraver’s power is sufficient for most materials, though it requires careful adjustment for optimal results. Precision in handling small text and detailed graphics was impressive, with minimal maintenance needed. The intuitive software made design accuracy straightforward, particularly beneficial for custom projects that demanded exactness.

This tool has streamlined my workflow, enabling me to take on more projects efficiently and meet customer expectations with professional-quality engravings.

Yan Rivera (verified owner) –

I absolutely love this laser tree cutter | laser engraver for cups! It made creating custom business logo cups so easy and precise—I couldn’t believe how quickly I got professional-looking results. Definitely a game-changer for my small business projects.

Robert Johnson –

Five stars for this laser engraver! The etching precision is impeccable, and the results are stunning. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable.