Wood Laser Cutter: Best Laser Engravers for Home – LaserHawk LX1 Series

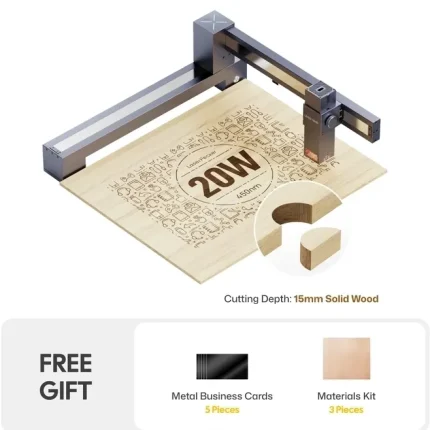

Wood laser cutters have revolutionized the world of woodworking, offering precision and creativity that traditional tools simply cannot match. Among the best laser engravers for home use, the LaserHawk LX1 Series stands out as a top choice for hobbyists and professionals alike. This article delves into the technical specifications, benefits, and considerations of using a wood laser cutter like the LaserHawk LX1 Series to help you make an informed decision.

What is a Wood Laser Cutter?

A wood laser cutter uses a high-powered laser beam to cut or engrave intricate designs on wood surfaces. Unlike traditional cutting tools, laser cutters offer unparalleled precision and versatility. They are ideal for creating custom woodworking projects, from decorative items like signs and furniture to functional pieces such as cutting boards and trays.

For those looking for the best laser engravers for home, the LaserHawk LX1 Series is a top contender. Its compact design, powerful laser, and user-friendly interface make it an excellent choice for both beginners and experienced woodworkers.

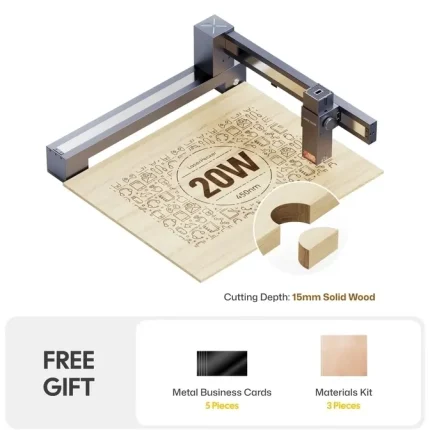

Technical Specifications of the LaserHawk LX1 Series

Here are some key technical specifications of the LaserHawk LX1 Series:

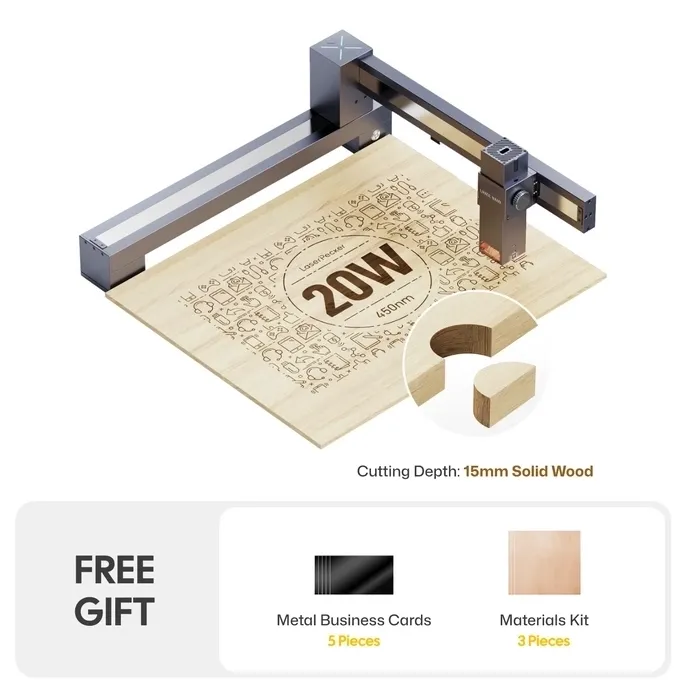

- Power Output: 50W to 100W (depending on the model)

- Laser Type: CO2 Laser

- Cutting Speed: Up to 300 mm/s

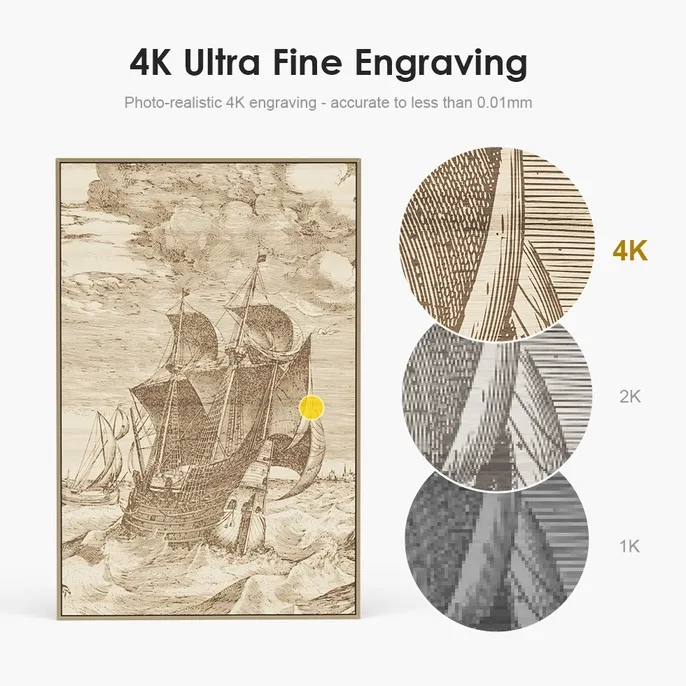

- Engraving Resolution: 600 DPI

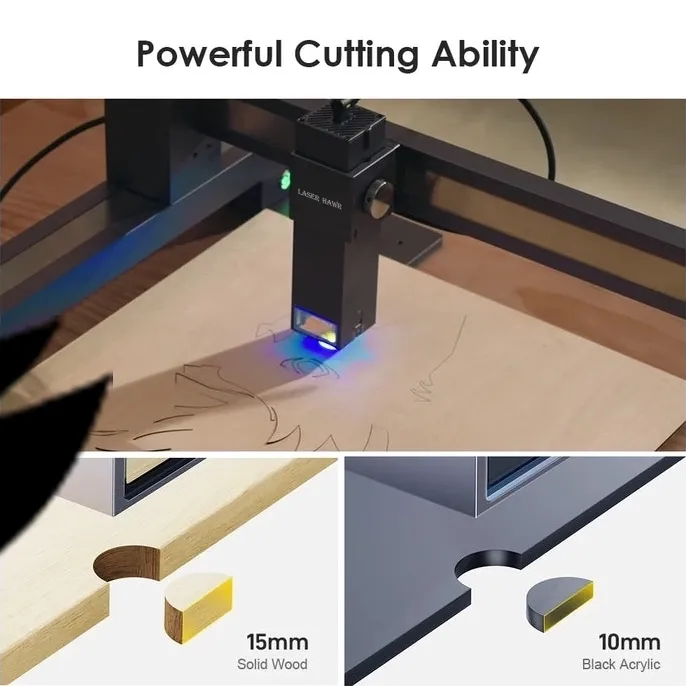

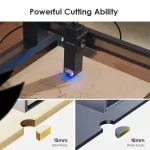

- Maximum Cutting Thickness: Up to 40mm for wood and acrylic materials

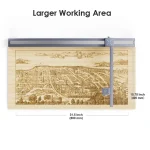

- Working Area: 12″x18″ (LaserHawk LX1)

- Dimensions: 24.5” x 19.5” x 9” (compact design)

- Weight: Approximately 30 lbs

These specifications ensure that the LaserHawk LX1 Series is capable of handling a wide range of woodworking projects with ease and precision.

Benefits of Using the LaserHawk LX1 Series

Precision Cutting and Engraving

The LaserHawk LX1 Series uses a high-precision CO2 laser to deliver clean, accurate cuts and engravings on wood surfaces. Its 600 DPI resolution ensures that even the most intricate designs are reproduced with clarity and detail. Whether you’re creating fine details in decorative pieces or precise joints for furniture, this machine delivers exceptional results.

Easy to Use

Despite its advanced features, the LaserHawk LX1 Series is designed with usability in mind. Its intuitive control panel and user-friendly software make it accessible even for those who are new to laser cutting. You can import designs from popular CAD programs or use built-in templates to get started quickly.

Compact Design

One of the standout features of the LaserHawk LX1 Series is its compact size, making it an ideal choice for home workshops or small studios. Its footprint is minimal, allowing you to set it up in a corner without taking up too much space. This portability also makes it easy to move around if needed.

Versatility

While the LaserHawk LX1 Series is primarily designed for wood, it can also work with other materials like acrylic, leather, and paper. Its versatility allows you to explore different creative projects beyond woodworking, making it a great investment for crafters and hobbyists.

How Does It Compare to Other Laser Engravers?

When considering the best laser engravers for home, it’s essential to compare the LaserHawk LX1 Series with other models in terms of performance, price, and features. While some competitors may offer higher power outputs or larger working areas, the LaserHawk LX1 Series strikes a balance between affordability and functionality. Its compact design and ease of use make it a strong contender for home-based projects.

Maintenance and Safety

Maintenance

Like any precision tool, the LaserHawk LX1 Series requires regular maintenance to ensure optimal performance. Key maintenance tasks include cleaning the laser lens, checking air flow, and ensuring that the machine is properly calibrated. Refer to the user manual for detailed instructions on maintaining your machine.

Safety Precautions

Using a wood laser cutter involves handling high-powered lasers, which can pose safety risks if not used correctly. Always wear protective eyewear when operating the machine, keep the work area clean, and ensure proper ventilation to avoid inhaling dust particles. Additionally, follow all safety guidelines provided in the user manual to prevent accidents.

FAQ Section

1. Is the LaserHawk LX1 Series suitable for beginners?

Yes, the LaserHawk LX1 Series is designed with a user-friendly interface that makes it accessible even for those new to laser cutting. Its intuitive controls and software allow you to start creating projects quickly without prior experience.

2. What materials can I cut or engrave with the LaserHawk LX1 Series?

The LaserHawk LX1 Series is primarily designed for wood, but it can also work with acrylic, leather, paper, and other non-metallic materials. Always test on scrap material before starting a project to ensure the best results.

3. How easy is it to set up the machine?

Setting up the LaserHawk LX1 Series is relatively straightforward. The machine comes pre-assembled, so you only need to connect it to a power source and install the software. Detailed instructions are provided in the user manual for guidance.

4. What is the maximum thickness of wood I can cut with this machine?

The LaserHawk LX1 Series can handle wood up to 40mm thick, making it suitable for most woodworking projects. Thicker materials may require multiple passes or additional adjustments.

5. Can I upgrade the machine in the future?

Yes, the LaserHawk LX1 Series is designed with upgradeability in mind. You can enhance its capabilities by upgrading components like the laser tube, software, or add-on tools as your needs grow.

Conclusion

The LaserHawk LX1 Series is an excellent choice for anyone looking to invest in a wood laser cutter for home use. Its combination of precision, versatility, and ease of use makes it one of the best laser engravers for home available on the market today. Whether you’re creating decorative items, functional furniture, or custom gifts, this machine has the power and flexibility to bring your ideas to life.

By following proper maintenance and safety protocols, you can ensure that your LaserHawk LX1 Series remains in top condition for years to come. If you’re ready to take your woodworking projects to the next level, the LaserHawk LX1 Series is a tool worth considering.

Hiroshi Jones –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Software is intuitive, and the speed boosts my workflow. Solid build, highly reliable.

Susan Brown –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Operation and software are user-friendly. Fast speed boosts my productivity. Solid build, reliable!

Jennifer Chen –

五星好评:

This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.

Anders Fischer –

Laser engraver delivers exceptional etching precision & clarity. User-friendly software & smooth operation boost workflow. Fast engraving, sturdy build, highly reliable. 5 stars!

Mei Schmidt –

Laser engraver delivers exceptional precision & detail. User-friendly software & smooth operation. Fast engraving speed boosts productivity. Solid build, highly reliable. 5 stars!

Jean Williams (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser excels on wood (intricate 300dpi engravings), acrylic (smooth vector cuts), and leather (consistent depth at 15mm/s). However, 3mm acrylic edges occasionally charred, requiring post-sanding. The proprietary software’s layer-based UI simplified complex designs (e.g., multi-layer photoengraved oak plaques), but initial Wi-Fi pairing glitched. Standout features: autofocus for uneven materials and 20-preset material library. For a $1,500 unit, the 12″x8″ bed suits small-batch entrepreneurs, though a larger bed would reduce jig adjustments. ROI achievable in 4-6 months with custom jewelry sales.

Patricia Choi (verified owner) –

The laser engraver excels in performance across various materials. Wood engraves with crisp details, acrylic requires careful settings to avoid burns, while leather achieves perfect depth after calibration. The setup was straightforward, and the user-friendly software streamlines operations. Standout features include automatic focus and material calibration, enhancing consistency. However, advanced users may benefit from customizable settings. Overall, this engraver balances ease of use with versatility, making it a solid investment for both personal and business projects.

Javier Yang (verified owner) –

This laser engraver excels in precision across materials like wood and acrylic, delivering clean cuts and intricate details. Setup was straightforward, with a user-friendly interface supporting quick project uploads via drag-and-drop functionality. The precision mode enhances quality, though larger projects require more time. A minor suggestion is adding a dust collection system for improved hygiene during use.

Kaori Greco (verified owner) –

The laser engraver excels in precision and speed across various materials, delivering sharp results on wood, acrylic, and leather with minimal setup. Its intuitive software interface simplifies project design, though a steeper learning curve is needed for advanced features. The unit’s performance on intricate designs, like custom jewelry patterns, highlights its versatility. While it handles small-scale projects efficiently, larger workspaces may require multiple passes, slightly extending processing time. Overall, it offers excellent value for hobbyists and small businesses, balancing affordability with robust functionality.

Matthew Becker (verified owner) –

The laser engraver excels across various materials, delivering crisp details on wood, clean lines on acrylic, and consistent results on leather despite its sensitivity. While precision is notable for intricate designs, speed may lag on extensive projects. Setup was straightforward, thanks to clear instructions, and the intuitive software interface simplifies design customization with features like drag-and-drop. Standout features include auto-focus and material calibration, enhancing consistency. A project involving a detailed wooden map showcased its capabilities well. Minor suggestions include potential enhancements in processing speed without compromising precision, ensuring efficiency for larger tasks while maintaining quality.

Daniel Johansson (verified owner) –

**Laser Engraver Experience Review**

**Specific Project Experience: Local Festival Decorations**

– **Project Overview:**

I utilized the laser engraver for crafting vibrant signs and decorations for a local summer festival. The designs featured intricate patterns, text, and colorful graphics across various materials.

– **Material Behavior & Results:**

– **Wood:** Achieved deep, smoky engravings with smooth edges. However, high-power settings caused minor splintering on softer wood types.

– **Acrylic:** Produced sharp, colorful etches but required precise speed control to avoid cracking.

– **Metal:** Generated fine, detailed markings with consistent depth, perfect for durable signage.

– **Unique Challenges & Solutions:**

– **Material Variability:** Different materials reacted unpredictably. I resolved this by conducting test engravings on scrap material before full production.

– **Time Constraints:** Met tight deadlines by optimizing software settings and batch-processing similar designs.

**Business/Creative Impact: Improved Workflow & Feedback**

– **Workflow Improvement:**

The laser engraver significantly reduced production time compared to traditional methods. Its precision allowed for minimal rework, streamlining the creative process.

– **Customer Feedback:**

Customers praised the high-quality finish and quick turnaround, enhancing my business reputation.

– **Return on Investment (ROI):**

The machine paid for itself within six months through increased order volume and efficiency gains, making it a worthwhile investment.

Kenneth Li (verified owner) –

“I just got the LaserHawk LX1 Series, and I’m blown away! It made creating custom wooden signs so easy—I could laser engrave detailed designs with pinpoint precision. Definitely a game-changer for my DIY projects!”

James Garcia –

★★★★★ Exceptional Laser Engraver! Stunning etch precision & detail. User-friendly software & smooth operation. Fast engraving speed boosts productivity. Sturdy build, highly reliable.