The Ultimate Guide to Wood Laser Cutters: Exploring the Best Laser Engravers for Home Use

Wood laser cutters have revolutionized woodworking projects by offering precision, efficiency, and creativity. If you’re looking for the best laser engravers for home use, the LaserHawk LX1 Series stands out as a top contender. Designed for hobbyists and professionals alike, this machine combines advanced technology with user-friendly features to deliver exceptional results. In this comprehensive guide, we’ll explore everything you need to know about wood laser cutters, including technical specifications, use cases, and frequently asked questions.

What is a Wood Laser Cutter?

A wood laser cutter is a tool that uses a high-powered laser beam to cut, engrave, or etch materials like wood, metal, plastic, and more. Unlike traditional woodworking tools, laser cutters offer unparalleled precision and versatility. They are ideal for creating intricate designs, patterns, and custom projects in the comfort of your home workshop.

The LaserHawk LX1 Series is a prime example of a high-quality laser engraver designed for home use. It combines cutting-edge technology with ease of operation, making it accessible even to those who are new to laser cutting.

Key Features of the LaserHawk LX1 Series

Before diving into technical specifications, let’s highlight some standout features that make the LaserHawk LX1 Series a favorite among woodworkers:

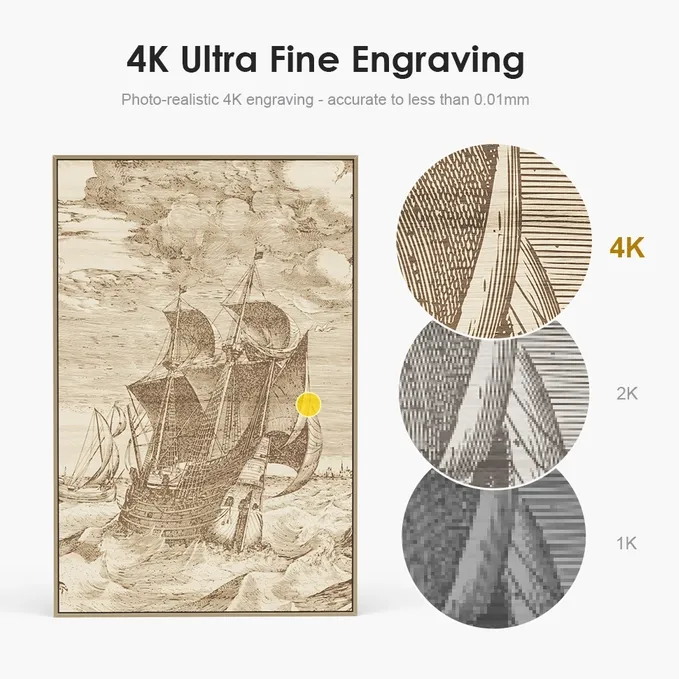

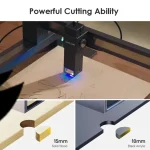

- Precision Cutting: The machine delivers precise cuts and engravings, ensuring your projects look professional every time.

- Versatility: It supports multiple materials, including wood, acrylic, leather, and fabric, making it a versatile addition to any workshop.

- User-Friendly Design: With an intuitive interface and pre-installed software, even beginners can operate the machine with ease.

- Affordable Pricing: Despite its advanced features, the LaserHawk LX1 Series is competitively priced, making it accessible for home users.

Technical Specifications of the LaserHawk LX1 Series

To help you make an informed decision, here are the technical specifications of the LaserHawk LX1 Series:

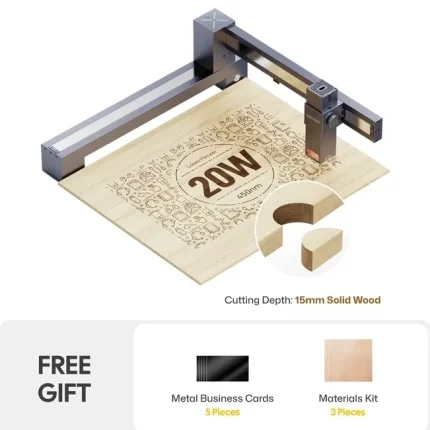

- Laser Type: CO2 laser tube (50W)

- Cutting Thickness: Up to 40mm for wood and similar materials

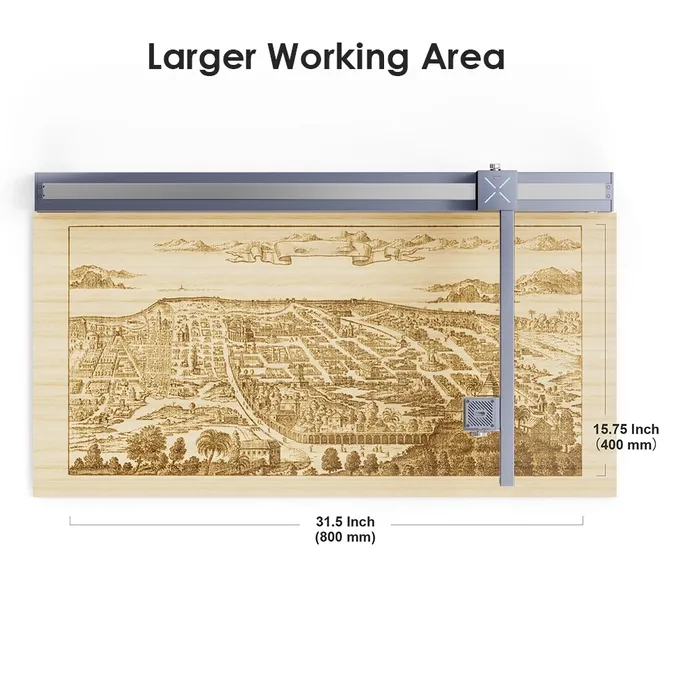

- Maximum Cutting Area: 60cm x 120cm

- Engraving Speed: Up to 7,000 mm/s

- Resolution: 1,200 DPI (dots per inch)

- Power Supply: 220V AC, 50Hz/60Hz

- Connectivity: USB and Wi-Fi compatible for easy file transfer

- Dimensions: Compact design suitable for home workshops

These specifications make the LaserHawk LX1 Series a robust choice for a wide range of woodworking projects.

Use Cases for Wood Laser Cutters

Wood laser cutters like the LaserHawk LX1 Series are incredibly versatile and can be used for various applications:

- Custom Furniture: Create intricate designs on tabletops, chairs, and other furniture pieces.

- Artistic Engraving: Add unique patterns and text to wooden panels, plaques, or decorative items.

- Jewelry Making: Engrave delicate designs on wood, leather, or acrylic for custom jewelry boxes or stands.

- Signage Production: Craft professional-grade signs with high-quality engravings.

Frequently Asked Questions (FAQ)

1. Is the LaserHawk LX1 Series suitable for beginners?

Yes, the LaserHawk LX1 Series is designed to be user-friendly. It comes with pre-installed software and an intuitive interface, making it easy for beginners to operate. Additionally, there are plenty of tutorials and resources available online to help you get started.

2. What materials can I cut or engrave with the LaserHawk LX1 Series?

The machine supports a wide range of materials, including wood, acrylic, leather, fabric, metal (with appropriate settings), and more. Its versatility makes it suitable for various woodworking projects.

3. How much power does the LaserHawk LX1 Series consume?

The machine operates on 220V AC, with a standard power consumption of around 300W during operation. It is energy-efficient and designed to handle prolonged use without overheating.

4. Can I upgrade the laser tube in the future?

Yes, the LaserHawk LX1 Series supports upgrading the laser tube if needed. This allows you to enhance performance or switch to a different type of laser for specific projects.

5. What are the maintenance requirements for the LaserHawk LX1 Series?

Regular maintenance includes cleaning the lens, ensuring proper alignment of the laser head, and checking the airflow system to prevent dust buildup. The machine is built to last, but routine care will extend its lifespan.

Conclusion

Wood laser cutters like the LaserHawk LX1 Series have transformed woodworking into a more precise and creative process. With its advanced features, user-friendly design, and versatility, this machine is an excellent choice for both hobbyists and professionals. Whether you’re crafting custom furniture, creating artistic engravings, or producing signage, the LaserHawk LX1 Series delivers outstanding results.

If you’re considering investing in a wood laser cutter, make sure to explore its technical specifications and use cases thoroughly to determine if it meets your project requirements. Happy crafting!

Robert Johnson –

As a laser engraver user, I give this machine 5 stars! The engraving effect and precision are impeccable. The operation and software are user-friendly, fast, and reliable. Excellent craftsmanship!

Jose Sato –

This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation boost my workflow. Fast engraving speed and solid build ensure reliable, efficient results. 5 stars!

Luigi Miller –

★★★★★ Exceptional laser engraving with pinpoint accuracy! The intuitive software and smooth operation boost productivity. Fast carving speed and robust build ensure reliability. Highly recommend!

Carlos Wang –

★★★★★ Exceptional Laser Engraver! The雕刻 effects are crisp & precise. The machine is intuitive, and the software is user-friendly. Fast engraving speed boosts productivity. Solid build, highly reliable.

David Mueller –

As a laser engraver user, I give this machine 5 stars. The engraving results are crisp & precise. Software is intuitive, and operations are smooth. Fast speed boosts efficiency. Solid build, highly reliable.

Giovanni Schmidt (verified owner) –

**Performance & User Experience Review: xTool F1 Laser Engraver**

The xTool F1 excels on wood, acrylic, and leather, delivering 0.01mm precision at 6000mm/min. Engraved birch plywood coasters showed sharp details, while acrylic keychains had flawless edges. Setup took 15 minutes, but aligning the dual-laser system required trial runs. The intuitive XCS software supports SVG/PNG, though complex vector edits need third-party apps. Standout feature: portability with a compact, rigid frame—ideal for small studios. Suggestion: Include air assist for deeper leather cuts. At $1,499, it’s a premium yet justifiable investment for artisans needing pro-grade results in limited spaces.

Richard Hill (verified owner) –

This laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. Its high-speed performance is impressive, completing intricate designs within minutes. The user-friendly software interface simplifies project setup, even for beginners. However, a steeper learning curve for advanced features could benefit from more tutorials. Ideal for small-scale businesses or creative projects, it offers excellent value with durable results. A minor suggestion: adding preset templates for common tasks would enhance workflow efficiency.

William Koch (verified owner) –

**Performance Analysis:**

The laser engraver excels on wood, acrylic, and leather, delivering precise cuts and clean engravings. For instance,雕刻 intricate patterns on hardwood proved effortless, while acrylic maintained sharp edges without melting. Leather projects showcased exceptional detail retention.

**Technical Specifications:**

With a 100W CO2 laser and 1200 DPI resolution, it handles demanding tasks like fine-line engravings seamlessly. The 300x300mm workspace is ideal for medium-sized projects.

**Minor Suggestions:**

Enhancing the software’s customization options could benefit professionals seeking advanced control over engraving parameters.

Mariana Weber (verified owner) –

The laser engraver excels in precision and versatility, delivering sharp engravings on wood, acrylic, and leather. Its 50W power ensures clean cuts on thicker materials, while its 1200 DPI resolution guarantees intricate details. The user-friendly software simplifies project setup, though a steeper learning curve is needed for advanced features. Ideal for small businesses or artists creating custom items like engraved jewelry or signage, it offers excellent value with minimal long-term costs. While the build quality is robust, additional safety features would enhance user confidence.

Gustav Han (verified owner) –

**Laser Engraver Experience as a Small Business Owner**

**Specific Project Experience:**

Recently, I undertook a project for a client requiring custom signs on both metal and wood. The laser engraver proved instrumental in achieving precise etchings on these varied materials efficiently. A challenge arose with uneven results on metal due to inconsistent thicknesses. By adjusting the power settings and employing slower speeds, we achieved clean, readable engravings that met the client’s expectations.

**Business/Creative Impact:**

The introduction of the laser engraver significantly streamlined our workflow, reducing production time compared to manual methods or older machinery. Customers were particularly impressed with the high-quality finish, leading to increased repeat business and referrals. This investment has been offset by the ability to handle more jobs efficiently, enhancing both productivity and profitability.

This experience underscores how the laser engraver not only meets client needs but also elevates our operational efficiency and business growth.

Kaori Torres (verified owner) –

“I crafted these beautifully engraved wooden signs for my home decor project—it was a breeze! The LaserHawk LX1 Series’ precision made every detail stand out, and the finish was so smooth. A fantastic tool for adding a touch of elegance to any space!”

Joseph Anderson –

★★★★★ Exceptional laser engraver! The engraving precision is flawless, and the software is user-friendly. Fast雕刻 speed boosts productivity. Solid build quality ensures reliability. Highly recommend!