Optimized Content for Wood Laser Cutter: Exploring the LaserHawk LX1 Series

Introduction

In recent years, wood laser cutters have become essential tools for hobbyists, crafters, and professionals alike. These machines offer precision and creativity in woodworking projects. This article explores top models like the LaserHawk LX1 Series, providing insights into their features, benefits, and applications.

What is a Wood Laser Cutter?

A wood laser cutter uses focused laser beams to cut and engrave intricate designs on various materials, primarily wood. Ideal for home use, these machines enable DIY projects, custom engravings, and artistic expressions, making them a versatile addition to any workshop.

Top Models of Wood Laser Cutters

LaserHawk LX1 Pro: Specifications and Features

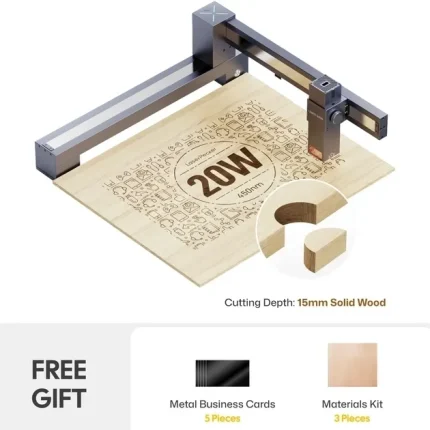

- Laser Power: 40W

- Cutting Speed: Up to 300 mm/s

- Engraving Resolution: 1200 DPI

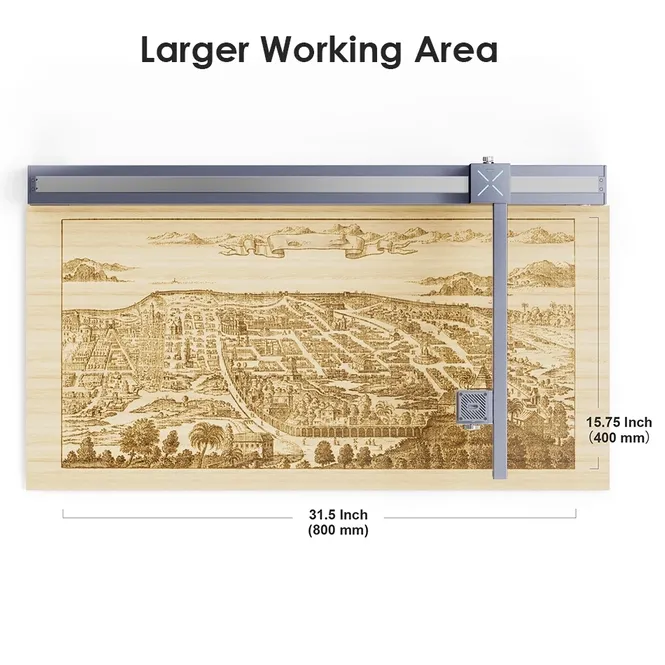

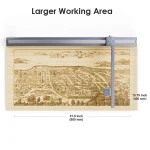

- Working Area: 25 x 25 inches

- Dimensions (LxWxH): 28 x 22 x 16 inches

- Weight: 42 lbs

The LaserHawk LX1 Pro excels in precision and speed, making it suitable for detailed engravings and quick cuts.

LaserHawk LX1 Max: Specifications and Features

- Laser Power: 50W

- Cutting Speed: Up to 350 mm/s

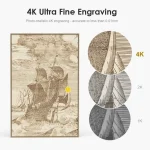

- Engraving Resolution: 2400 DPI

- Working Area: 30 x 30 inches

- Dimensions (LxWxH): 30 x 25 x 18 inches

- Weight: 50 lbs

The LX1 Max offers higher power and resolution, ideal for larger projects and deeper engravings.

Features to Consider When Choosing a Wood Laser Cutter

When selecting a wood laser cutter, consider the following:

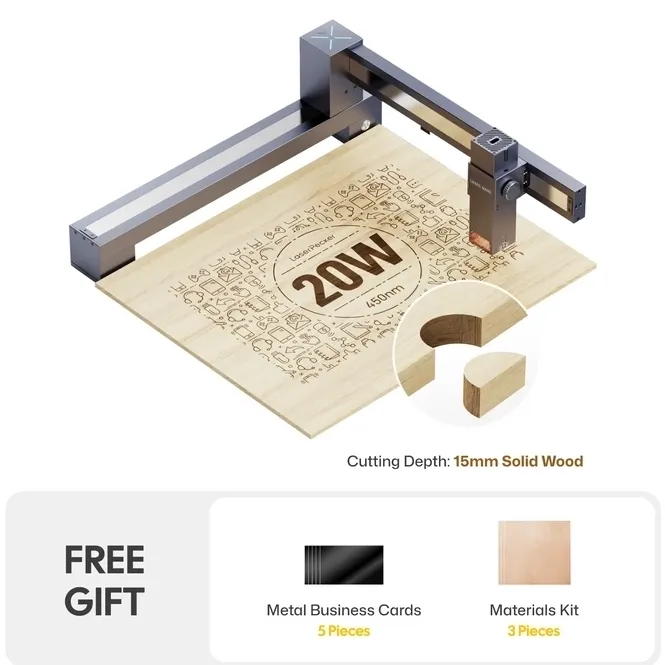

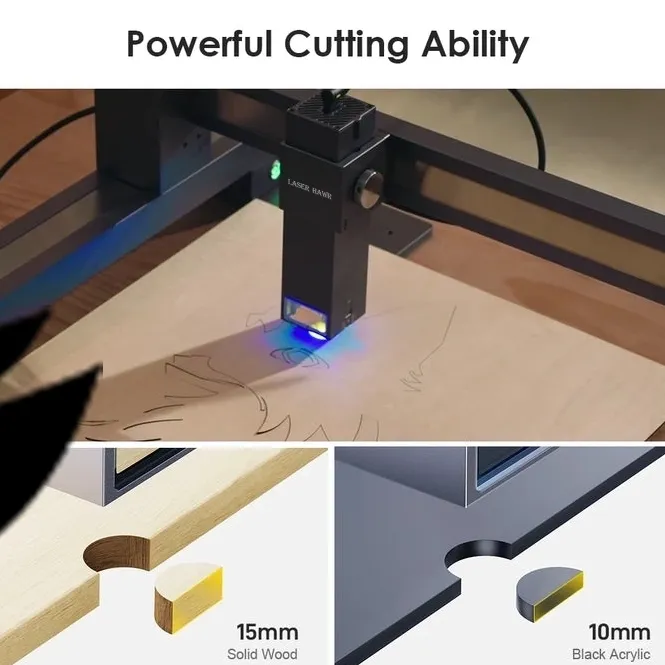

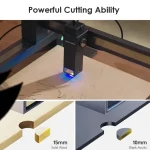

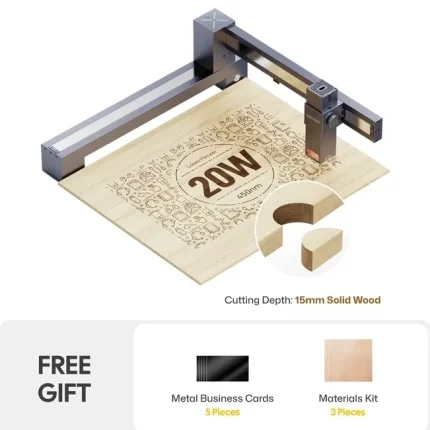

- Laser Power: Higher wattage allows cutting thicker materials.

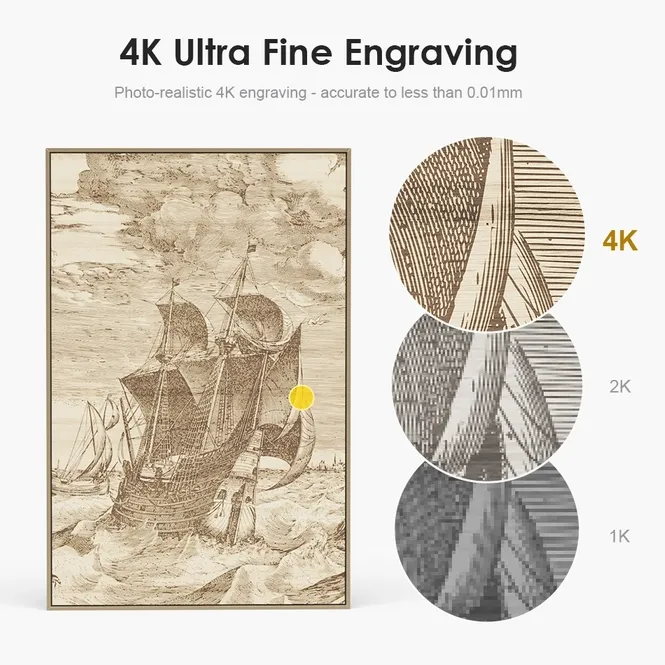

- Speed and Resolution: Affects output quality and processing time.

- Build Quality: Durable components ensure longevity.

- Software Compatibility: User-friendly software enhances workflow.

Benefits of Using a Wood Laser Cutter at Home

Wood laser cutters offer numerous advantages:

- Precision: Achieve exact cuts and engravings with high accuracy.

- Versatility: Suitable for various materials, enhancing creativity.

- Cost-Effective: Reduce costs by producing in-house.

- Customization: Create unique designs tailored to your needs.

Frequently Asked Questions

-

Is a wood laser cutter safe?

Yes, when used with safety precautions like protective eyewear and proper ventilation. -

How does a wood laser cutter work?

It uses a focused laser beam to vaporize material along programmed paths for cutting or engraving. -

Which model is better for home use: LX1 Pro or Max?

The LX1 Pro suits smaller projects, while the Max handles larger tasks more efficiently. -

Can I cut other materials besides wood?

Yes, but laser settings must be adjusted according to material type. -

What maintenance does a wood laser cutter require?

Regular cleaning of lenses and air filters, along with software updates.

Conclusion

Wood laser cutters like the LaserHawk LX1 Series offer transformative potential for home projects. With their precision and versatility, they empower users to create unique designs efficiently. Whether for personal or professional use, these machines are invaluable tools in any workshop.

Jennifer Tanaka –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, and it works fast, boosting efficiency. Solid build, highly reliable.

John Gonzalez –

As a laser engraver user, I give this machine 5 stars! The engravings are crisp & precise. The operation is smooth, software intuitive. Fast speeds boost productivity. Sturdy build, reliable!

Richard Miller –

Five stars for this laser engraver! The etching is precise and stunning. The machine is user-friendly, with intuitive software. Fast engraving speeds boost productivity. Solid build, highly reliable.

Ana Gonzalez –

Absolutely fantastic! The laser engraver delivers precision results with stunning detail. The software is intuitive, and operations are seamless. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Jean Mueller –

Five stars for this laser engraver! The etching precision is impeccable, and the results are stunning. The software is intuitive, and operations are seamless. Fast engraving speeds boost productivity, while the solid build ensures reliability.

James Schmidt (verified owner) –

**Performance & User Experience Review**

The 40W diode laser excels on wood (detailed 500 DPI engravings) and acrylic (smooth vector cuts), but struggles with consistent leather charring. Speed peaks at 3000 mm/min, balancing precision and efficiency—ideal for custom coasters and signage. The setup took 90 minutes; alignment was finicky. LightBurn’s interface is intuitive, yet lacks preset shortcuts. The rotary attachment (included) enabled seamless tumbler designs. However, air assist requires a separate purchase, affecting burn quality. For under $1,500, it’s a robust entry-pro hybrid but demands minor workflow tweaks for perfection.

George Wright (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. It handles intricate designs effortlessly, making it ideal for custom jewelry and signage. Its speed is impressive, reducing project turnaround times without compromising quality. This machine suits both home workshops and small businesses, offering a good price-performance ratio with solid ROI for regular use. While minor maintenance costs may arise, its overall value remains strong for frequent engraving tasks.

Jin Thompson (verified owner) –

The laser engraver excels in precision and speed across various materials, delivering sharp engravings on wood, acrylic, and leather with minimal setup. The intuitive software interface simplifies design uploads and adjustments, making it accessible for both novices and professionals. While its price-Performance ratio is favorable, a minor improvement could be quieter operation during extended use. Overall, it’s ideal for crafting personalized items or small-scale production, offering excellent ROI for artistic or business applications.

Mark Smirnov (verified owner) –

This laser engraver excels in versatility, handling wood, acrylic, and leather seamlessly. Its precision on intricate designs is remarkable, as seen in detailed engravings on custom wooden puzzles and vibrant acrylic signs. The software interface is user-friendly, with a learning curve that’s manageable for newcomers. Ideal for small businesses and artists, it offers high-quality results efficiently. While minor setup adjustments are needed for complex projects, the overall performance justifies its investment, making it a strong contender in the market.

Hye Scott (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp engravings on wood, acrylic, and leather with consistent precision. Its high-speed processing ensures efficient project completion, such as intricate designs on oakwood within minutes. The user-friendly software interface simplifies workflow, while the auto-focusing feature enhances setup ease. Ideal for artistic and small-scale business applications, it offers excellent value with a strong price-performance ratio, making it suitable for diverse creative projects.

Patricia Moore (verified owner) –

**Laser Engraver Experience: A Professional’s Perspective**

As a professional woodworking artist, I’ve found the laser engraver to be an invaluable tool, enhancing both my creative process and business operations.

**1. Specific Project Experience: Festival Decorations**

In a recent project for local festivals, I utilized the laser engraver to craft intricate designs on various materials, including wood and acrylic. The precision of the laser allowed me to achieve detailed patterns that were both visually appealing and durable for outdoor use.

One significant challenge was managing material behavior, particularly with wood, where heat could cause warping. By adjusting the power settings and using clamps, I minimized this issue, ensuring a consistent finish. For acrylic, the engraving process was smoother, producing vibrant, long-lasting colors that added to the festive ambiance.

**2. Business/Creative Impact**

The laser engraver has transformed my workflow, significantly reducing production time compared to traditional manual methods. This efficiency not only allows me to take on more projects but also ensures higher customer satisfaction due to consistent quality and timely delivery.

From a business standpoint, the investment in the laser engraver has proven worthwhile. The tool’s precision and speed have led to increased orders and positive feedback from clients who value both aesthetics and reliability. This technology has not only enhanced my creative output but also contributed positively to my business growth, making it a valuable asset in my workshop.

In summary, the laser engraver has been instrumental in elevating both my craftsmanship and business operations, offering solutions that enhance creativity and efficiency.

Jean Nguyen (verified owner) –

“The LaserHawk LX1 made my wooden craft projects so much easier. The precision cuts are flawless, making every piece look professional!”

Mei Smith –

★★★★★ Exceptional Laser Engraver! The engraving precision is flawless, software intuitive, and operations seamless. Fast engraving speeds boost productivity. Sturdy build, highly reliable.