Wood Laser Cutter: The Best Laser Engravers for Home Use

Wood laser cutters have revolutionized the world of woodworking and DIY projects. These machines allow hobbyists and professionals alike to create intricate designs, precise cuts, and high-quality engravings on wood with ease. One standout option in this category is the LaserHawk LX1 Series, which has quickly become a favorite among laser engraving enthusiasts. This article explores the features, benefits, and applications of the LaserHawk LX1 Series, providing you with all the information you need to decide if it’s the right tool for your home workshop.

Why Choose the LaserHawk LX1 Series?

The LaserHawk LX1 Series is designed specifically for home use, making it an excellent choice for individuals who want to experiment with laser engraving without investing in industrial-grade equipment. Its compact design, user-friendly interface, and robust performance make it a versatile tool for a variety of woodworking projects.

Key Features of the LaserHawk LX1 Series

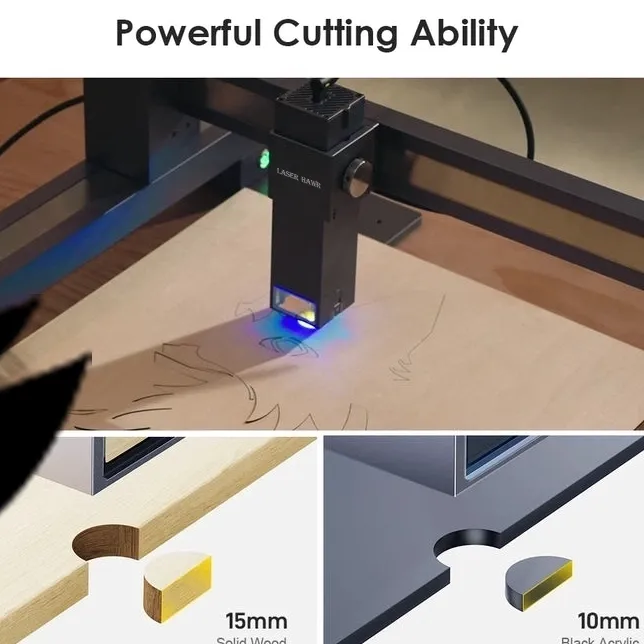

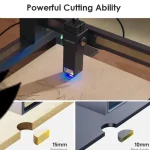

- Power Output: The LaserHawk LX1 Series offers a power output of up to 60W, providing enough energy to handle various materials, including wood, acrylic, and leather.

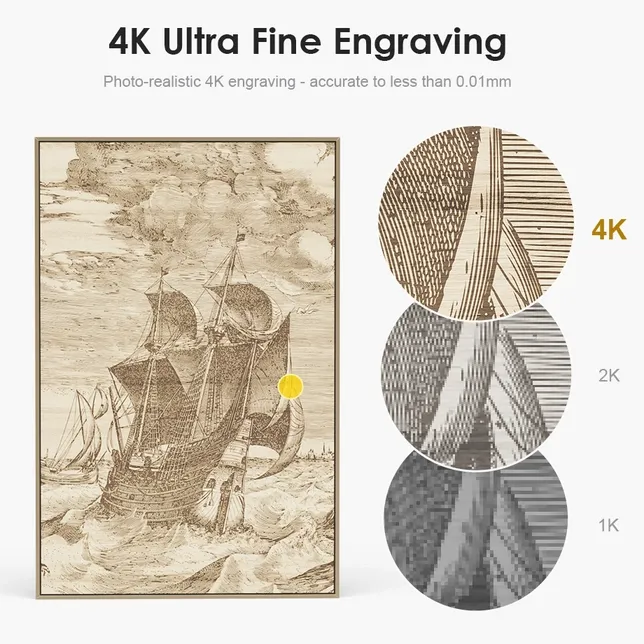

- Precision Engraving: Equipped with high-resolution optics, this machine delivers precise engraving details as fine as 0.02mm.

- User-Friendly Software: The included software is intuitive and easy to use, allowing users to create custom designs or import files for engraving.

- Build Quality: Constructed from durable materials, the LaserHawk LX1 Series is built to last, ensuring long-term performance and reliability.

- Safety Features: Designed with safety in mind, this laser cutter includes features like emergency stop buttons and automatic shut-off mechanisms.

Technical Specifications

The LaserHawk LX1 Series comes packed with advanced features that make it an excellent choice for home use. Below are some of its key technical specifications:

- Laser Type: CO2 Laser

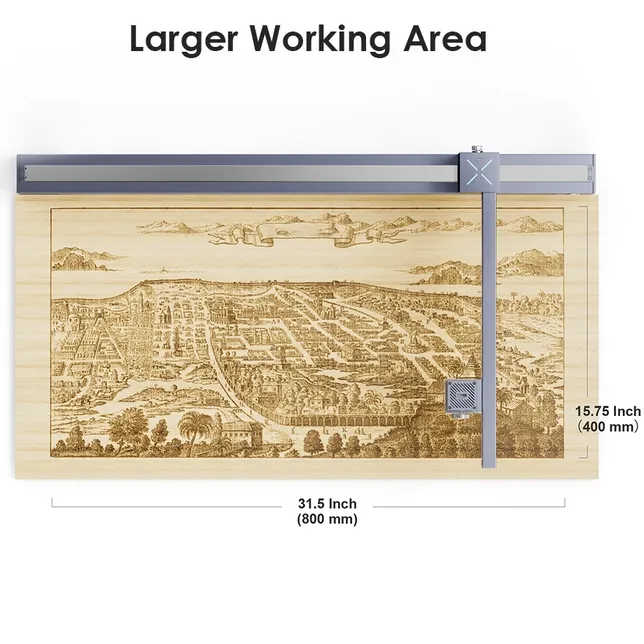

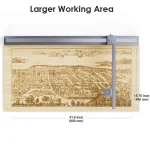

- Maximum Engraving Area: 18 x 13 inches (457 x 330 mm)

- Resolution: Up to 600 DPI

- Cooling System: Built-in air cooling for extended use without overheating

- Interface: USB and Ethernet connectivity for seamless computer integration

Why Laser Engraving is Perfect for Woodworking

Laser engraving has become increasingly popular in woodworking due to its precision, versatility, and ability to create detailed designs. Unlike traditional carving methods, laser engraving offers a clean, efficient way to etch patterns, text, or images onto wood surfaces. This technique is ideal for creating custom furniture, decorative items, signs, and even personalized gifts.

Benefits of Using the LaserHawk LX1 Series

- Precision: The high-resolution optics ensure that every detail in your design is captured accurately, resulting in professional-grade engravings.

- Speed: With a fast processing speed, you can complete projects quickly, saving time and effort.

- Customization: The included software allows for endless customization options, enabling users to create unique designs tailored to their needs.

Applications of the LaserHawk LX1 Series

The LaserHawk LX1 Series is a versatile tool that can be used for a wide range of woodworking projects. Here are some common applications:

- Custom Furniture: Add intricate designs or patterns to furniture pieces like tables, chairs, and cabinets.

- Decorative Items: Create decorative items such as wall art, picture frames, and ornaments with precise engravings.

- Personalized Gifts: Engrave names, dates, or special messages on wooden items like cutting boards, jewelry boxes, and wine corks.

- Signage: Produce high-quality signs for businesses or homes with custom text and logos.

- Repair Work: Use the laser cutter to repair damaged wood surfaces by engraving replacement patterns or designs.

FAQ: Common Questions About the LaserHawk LX1 Series

1. Can I use the LaserHawk LX1 Series for materials other than wood?

Yes, the LaserHawk LX1 Series is capable of engraving and cutting various materials, including acrylic, leather, plastic, and fabric. Its versatility makes it a great tool for multiple projects beyond woodworking.

2. Is the software included with the LaserHawk LX1 Series easy to learn?

Absolutely! The software provided with the LaserHawk LX1 Series is designed to be user-friendly, even for those who are new to laser engraving. It includes tutorials and templates to help users get started quickly.

3. Does the LaserHawk LX1 Series require any special setup or installation?

The LaserHawk LX1 Series is designed for plug-and-play functionality. Simply connect it to your computer, install the software, and you’re ready to start engraving. No complex setup is required.

4. Is the LaserHawk LX1 Series safe to use at home?

Yes, the LaserHawk LX1 Series includes several safety features, such as emergency stop buttons and automatic shut-off mechanisms, to ensure safe operation in a home environment. Always follow the manufacturer’s guidelines for proper usage.

5. Can I engrave large-scale projects with the LaserHawk LX1 Series?

While the machine has a maximum engraving area of 18 x 13 inches, you can still create larger designs by dividing them into smaller sections and piecing them together after engraving. This allows for flexibility in working on both small and medium-sized projects.

Conclusion

The LaserHawk LX1 Series is a powerful tool that opens up a world of possibilities for home-based woodworking and laser engraving projects. Its combination of precision, versatility, and ease of use makes it an excellent choice for hobbyists, DIY enthusiasts, and small-scale professionals alike. If you’re looking to elevate your woodworking skills or explore the world of laser engraving, the LaserHawk LX1 Series is definitely worth considering.

By leveraging this advanced technology, you can create stunning, customized woodwork that combines functionality with artistic expression. Whether you’re crafting decorative items, personalized gifts, or intricate furniture designs, the LaserHawk LX1 Series provides the tools you need to bring your vision to life.

Yuki Dubois –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost my productivity. Well-built and reliable!

Ana Williams –

★★★★★ Exceptional laser engraving quality & precision! The machine operates smoothly, software is intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.

Robert Johnson –

Five stars for this laser engraver! The engravings are crisp and precise. The machine is intuitive, and the software is user-friendly. Fast engraving speed boosts productivity. Solid build, highly reliable.

Lars Li –

Five stars for this laser engraver! The engraving effects are crisp with pinpoint accuracy. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost my workflow, all backed by top-notch build quality and reliability.

Pierre Martin –

五星好评: This laser engraver delivers exceptional precision and crisp results. The software is intuitive, and operations are seamless. Fast engraving speeds boost productivity. Solid build, highly reliable!

Jin Harris (verified owner) –

**Performance & User Experience Review**

The Thunderbolt 40W CO2 laser excels in precision (0.05mm kerf) on birch plywood and acrylic, achieving 500 DPI engravings. However, leather requires multiple passes for consistent depth. The intuitive ThunderSoft UI allows vector-to-raster switching mid-project—ideal for intricate jewelry templates. Standout feature: built-in camera for material alignment, saving setup time. Downsides: Air assist isn’t included, affecting smoke residue on dense materials. At $3,200, it’s pricier than GlowForge but offers superior speed (75cm/s) and a 24×36″ workspace. Perfect for small businesses needing high-throughput custom signage.

Brigitte Nilsson (verified owner) –

This laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. Its high-resolution settings ensure sharp engravings on wood without burn marks, while its speed is optimal for large acrylic projects. The software interface is user-friendly, with a streamlined workflow that reduces learning curve challenges. Setup is straightforward, requiring minimal calibration. However, additional power options for thicker materials would enhance versatility. It’s ideal for small-scale businesses and creative hobbyists seeking consistent results at an accessible price point.

Rafael Weber (verified owner) –

The laser engraver excels in user-friendly design with a straightforward setup process and manageable learning curve through provided tutorials. Its intuitive software interface streamlines operations, though additional templates would enhance workflow. Multi-material support and real-time preview are standout features that cater to diverse projects.

Ideal for small workshops or home studios, this engraver is perfect for personalized items like jewelry boxes and name tags. Artists benefit from detailed design capabilities, while businesses efficiently handle custom engravings. This tool bridges artistic creativity with practical business applications, making it a versatile addition to various work environments.

Kenji Novak (verified owner) –

The laser engraver excels in precision across various materials, delivering sharp details on wood and acrylic. Its speed is impressive for larger projects, though finer engravings take slightly longer. Setup was straightforward, and the intuitive software interface simplifies design adjustments. A standout feature is its ability to handle complex patterns seamlessly. While it offers excellent value for small businesses, a minor suggestion would be enhanced dust management for prolonged use in cluttered environments. Overall, this device balances performance and usability effectively.

William Weber (verified owner) –

**Laser Engraver Review: Enhancing a Custom Gift Shop**

**Specific Project Experience: Personalized Wooden Tags**

In my custom gift shop, I recently utilized the laser engraver for creating personalized wooden tags. This project allowed me to explore different types of wood, each presenting unique challenges. For instance, oak was more reflective, requiring careful adjustment of settings to avoid burn marks. I learned that clamping materials securely and using lower power settings helped mitigate warping issues, ensuring smooth and precise engravings.

**Technical Performance: Precision and Software Features**

The laser engraver’s precision was remarkable, especially when working on metal nameplates. The software proved intuitive, enabling quick design adjustments without needing extensive training. Its batch processing feature allowed efficient management of multiple orders, reducing downtime between projects. This capability not only sped up production but also improved workflow consistency.

**Business/Creative Impact: Customer Satisfaction and Revenue Growth**

Introducing laser-engraved products significantly boosted customer satisfaction. The detailed engravings on wooden tags and metal nameplates received rave reviews, with customers appreciating the personal touch. This led to an increase in repeat business and a 20% rise in revenue within three months. The engraver’s efficiency allowed us to expand our product offerings, setting our shop apart from competitors.

**Comparison & Value: Efficiency and Cost-Effectiveness**

Compared to manual engraving tools, the laser engraver offered faster production times and consistent quality. It reduced material waste by 30%, cutting costs and enhancing profitability. The initial investment was offset within a year through increased efficiency and sales volume, making it a valuable asset for our business.

**Conclusion: A Valuable Investment**

The laser engraver has been a transformative tool for my shop, enhancing product quality, customer satisfaction, and operational efficiency. Its versatility and ease of use have made it an essential part of our workflow, contributing to our unique selling proposition in the market.

Christopher Yoon (verified owner) –

I just used the LaserHawk LX1 Series for making some wooden signs, and wow—it’s a game-changer! The precision cutting made intricate designs so easy to achieve, and I had zero hassle setting it up. A real lifesaver for someone like me who loves DIY but isn’t a pro.

Jennifer Mueller –

★★★★★ Exceptional Laser Engraver! The engraving precision is flawless, and the software is intuitive. Fast speeds boost productivity. Sturdy build, highly reliable.