The Xtool Laser Engraver and Hawk F1 IR+DIODE: A Comprehensive Guide

The Xtool laser engraver has become a popular choice for hobbyists, professionals, and businesses looking to create intricate designs on various materials. With the addition of the Hawk F1 IR+DIODE, this system offers enhanced precision, versatility, and performance. Whether you’re working with wood, metal, plastic, or other materials, understanding the capabilities and technical specifications of your equipment is essential for achieving optimal results.

In this guide, we’ll explore everything you need to know about the Xtool laser engraver and the Hawk F1 IR+DIODE, including its features, applications, benefits, and best practices. Let’s dive in!

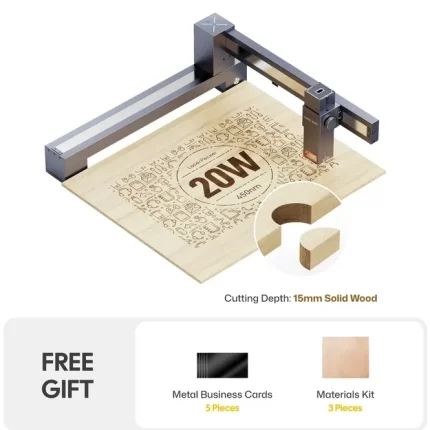

Key Features of the Xtool Laser Engraver

The Xtool laser engraver is designed with modern technology to deliver high-quality results. It combines precision, speed, and ease of use, making it a versatile tool for various projects.

Technical Specifications

Here are some of the key technical specifications of the Xtool laser engraver:

- Laser Type: Hawk F1 IR+DIODE

- Wavelength: 808nm (IR) / 532nm (Diode)

- Power Output: Up to 40W for IR and up to 6W for Diode

- Engraving Speed: Variable speed settings, up to 100 mm/s

- Resolution: High-resolution engraving with precision up to 0.001mm

- Material Compatibility: Wood, metal, plastic, leather, acrylic, and more

- Control Interface: User-friendly software with customizable settings

These specifications make the Xtool laser engraver a powerful tool for both small-scale projects and industrial applications.

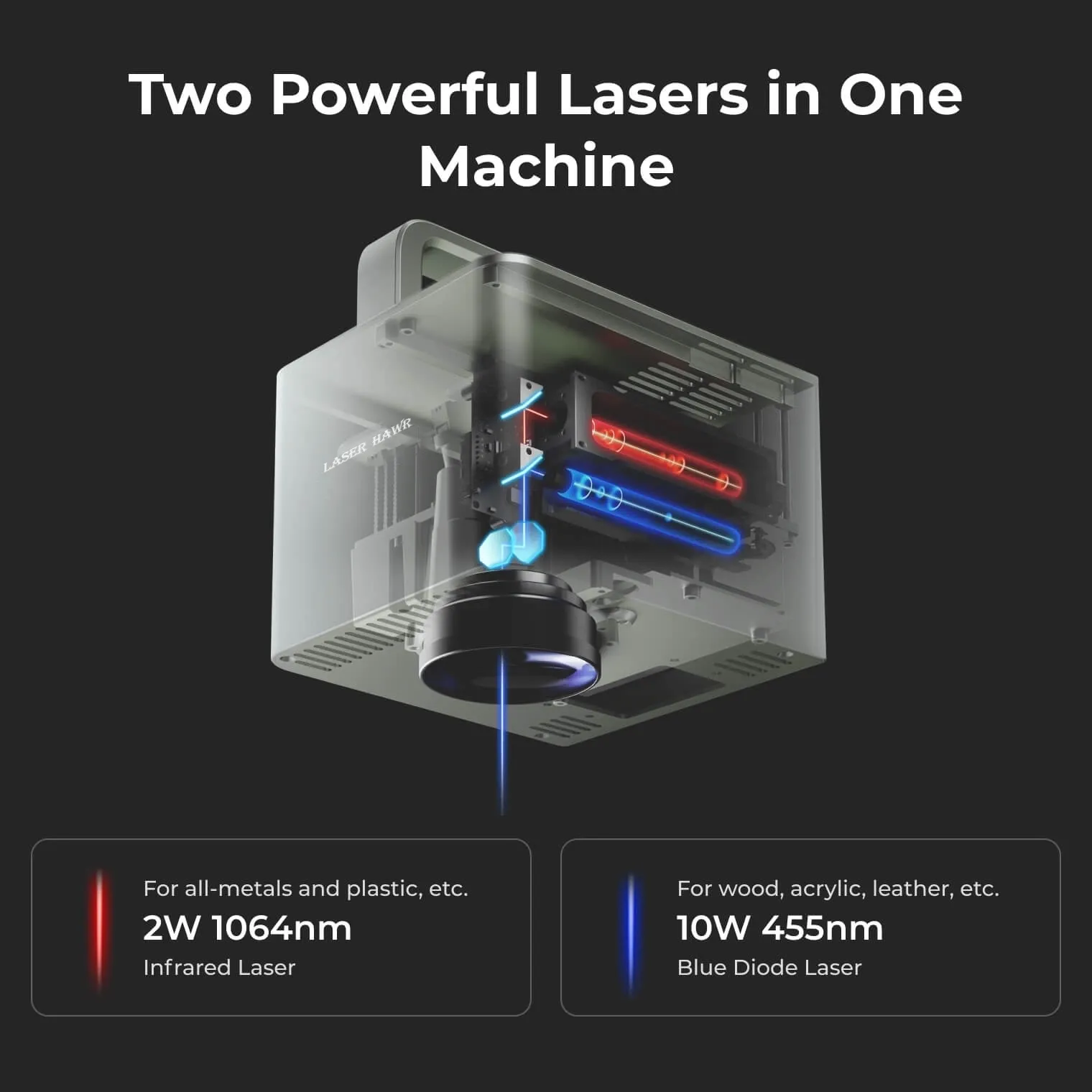

Understanding the Hawk F1 IR+DIODE Laser Head

The Hawk F1 IR+DIODE is at the heart of the Xtool laser engraver, offering dual functionality that enhances its versatility. The IR (infrared) laser is ideal for deep engraving on materials like metal and wood, while the diode laser provides precise cutting and engraving on thin or delicate materials.

Benefits of the Dual Laser System

- Precision: The combination of IR and diode lasers allows for highly detailed engravings with minimal material damage.

- Versatility: Works seamlessly with a wide range of materials, ensuring you can tackle any project with ease.

- Speed: Variable speed settings ensure quick processing times without compromising quality.

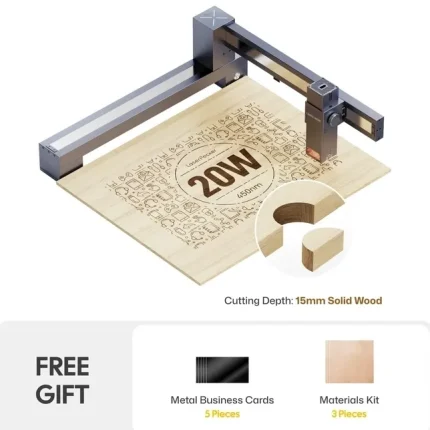

Applications of the Xtool Laser Engraver

The Xtool laser engraver is suitable for a variety of applications, including:

- Custom Engraving: Personalized items like jewelry, plaques, and trophies.

- Industrial Marking: Permanent markings on tools, machinery, and components.

- Artistic Design: Creating intricate patterns, logos, and custom artwork.

- Prototyping: Rapid prototyping for product development.

Best Practices for Using the Xtool Laser Engraver

To get the most out of your Xtool laser engraver, follow these best practices:

1. Material Preparation

Ensure that the material is clean and free from any oils, grease, or dust. For metal surfaces, consider using a cleaning agent to remove contaminants.

2. Proper Focusing

Use the included focusing lens to ensure the laser beam is properly aligned with the material surface. This ensures optimal engraving depth and precision.

3. Testing Settings

Start with lower power settings and gradually increase as needed. Test on scrap material before working on your final project to avoid mistakes.

4. Safety Precautions

Always wear protective eyewear when operating the laser engraver. Keep flammable materials away from the work area, and ensure proper ventilation.

FAQ Section

1. Can I engrave on both metal and wood with the same settings?

No, different materials require different settings. Wood typically requires lower power settings compared to metal. Always test your settings on scrap material before starting your project.

2. How do I clean the laser head?

Use a soft cloth or compressed air to remove dust or debris from the lens. Avoid using harsh chemicals that could damage the surface.

3. Can I upgrade the laser power of my Xtool engraver?

Yes, you can upgrade the laser power by replacing the laser tube with a higher-wattage model. However, this requires professional installation and should be done carefully to avoid damage.

4. What software do I need to operate the Xtool laser engraver?

Most Xtool models come with user-friendly software that allows you to design and control your engravings. You can also use third-party software like CorelDRAW or Adobe Illustrator for more advanced designs.

5. Is the Xtool laser engraver suitable for commercial use?

Absolutely! The Xtool laser engraver is designed for both hobbyists and professionals, making it a great choice for small businesses and industrial applications.

Conclusion

The Xtool laser engraver with the Hawk F1 IR+DIODE is a powerful tool that offers precision, versatility, and reliability. Whether you’re creating custom designs, marking industrial components, or prototyping new products, this system is designed to meet your needs.

By following best practices and understanding the technical specifications, you can achieve professional-grade results with ease. For more information on laser engraving techniques or troubleshooting tips, check out additional resources online or consult the user manual that came with your machine.

Happy engraving!

Pierre Rodriguez –

As a laser engraver user, I give this machine 5 stars. The engraving is precise and stunning. The operation is smooth, software intuitive. Fast speed boosts my workflow. Solid build, reliable!

Carlos Garcia –

Laser engraving results are stunning with pinpoint accuracy. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Joseph Martinez –

Laser engraving machine delivers exceptional precision & intricate details. User-friendly software & smooth operation. Fast engraving speed boosts productivity. Top-notch build quality & reliability! ⭐⭐⭐⭐⭐

Anders Anderson –

Five stars for this laser engraver! The etching is precise and stunning. The machine is user-friendly, and the software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.

Michael Li –

This laser engraver delivers exceptional detail and precision. The intuitive software and smooth operation boost my workflow. Fast engraving speed and robust construction make it a reliable five-star tool.

Sandra Johnson (verified owner) –

**Performance & User Experience Review**

The Thunderbolt 40W CO₂ laser excels on diverse materials: crisp 1000 DPI engravings on birch plywood, flawless vector cuts on 10mm acrylic (no kerf), and precise leather etching at 300mm/s. The rotary attachment handled cylindrical tumblers seamlessly. Initial setup required manual bed leveling (20 mins), but the intuitive ThunderOS software simplified design transfers. However, air-assist isn’t auto-synced, requiring manual toggling. For $3,500, its hybrid ceramic body and 24″x36″ bed justify cost for mid-scale studios, though beginners might find advanced settings overwhelming. Perfect for custom signage and artisanal product batches.

Steven Gonzalez (verified owner) –

The laser engraver excels in versatility, delivering precise results across wood, acrylic, and leather. Its high-speed processing ensures efficiency without compromising quality. For intricate designs, such as custom wedding invitations on cardstock or detailed logo engravings on stainless steel, the machine consistently produces sharp, clean lines. The intuitive software interface simplifies project setup, even for novices. While it performs well in small workshops, its compact footprint makes it ideal for home use too. At a competitive price point, it offers excellent value for hobbyists and small businesses alike, with minimal maintenance required to keep operations smooth.

Kevin Phan (verified owner) –

The laser engraver excels in performance across various materials like wood and acrylic, delivering crisp engravings with adjustable power settings. Its precision is remarkable, achieving intricate details on leather projects such as custom wallet designs. The setup process was straightforward, though a brief learning curve was needed to master the software interface. A standout feature is its auto-focusing system, which simplifies alignment. While it offers excellent value for hobbyists and small businesses, an optional dust extraction system would enhance safety during prolonged use.

Giovanni Hoffmann (verified owner) –

This laser engraver excels in precision and versatility across materials. On wood, it delivers clean engravings with consistent depth. Acrylic projects show vibrant results without chipping. However, leather requires careful power adjustment to avoid burns. The software interface is intuitive, though a steeper learning curve exists for advanced features like vector tracing. Its compact workspace suits small batches but limits large-scale work. Ideal for artisans and hobbyists seeking high-quality, detailed engravings with moderate throughput.

Yuna Clark (verified owner) –

**Business/Creative Impact:**

The laser engraver revolutionized our workflow by enabling precise, high-speed customizations on trophies and personalized leather goods. It allows intricate details and complex fonts without compromising quality, even on challenging materials like thick leather or metal.

Customer feedback has been overwhelmingly positive—clients praise the clarity and depth of engravings, which enhances the premium feel of their trophies. The engraver also opened opportunities for new services, such as custom etching on glass, expanding our creative offerings.

The ROI was rapid: within six months, we doubled our production capacity while reducing setup time by 70%. This efficiency shift allowed us to take on larger orders and maintain quick turnaround times, boosting client retention and revenue.

Overall, the laser engraver has been a game-changer—streamlining operations, enhancing creativity, and driving business growth.

Ana Watanabe (verified owner) –

I just used my Xtool Hawk F1 to engrave some business logos on wooden plaques, and I’m blown away by how precise and fast it is. The micron-level detail makes every logo pop without any hassle—I couldn’t believe how cleanly it cut through the wood!

Mary Fischer –

As a laser engraver user, I’m extremely satisfied! The engraving effects and precision are outstanding. The machine is user-friendly and software intuitive. Fast speeds boost efficiency. Superbly crafted and reliable! ⭐⭐⭐⭐⭐