Xtool Laser Engraver: A Comprehensive Guide to the Hawk F1 IR+DIODE

Laser engraving has become an indispensable tool for professionals in various industries, from industrial manufacturing to custom crafting. The Xtool laser engraver, specifically the Hawk F1 IR+DIODE model, stands out as a versatile and high-performance machine designed for precision and efficiency. In this guide, we will explore the features, technical specifications, and applications of this remarkable tool, ensuring you have all the information needed to make an informed decision.

What is the Xtool Laser Engraver?

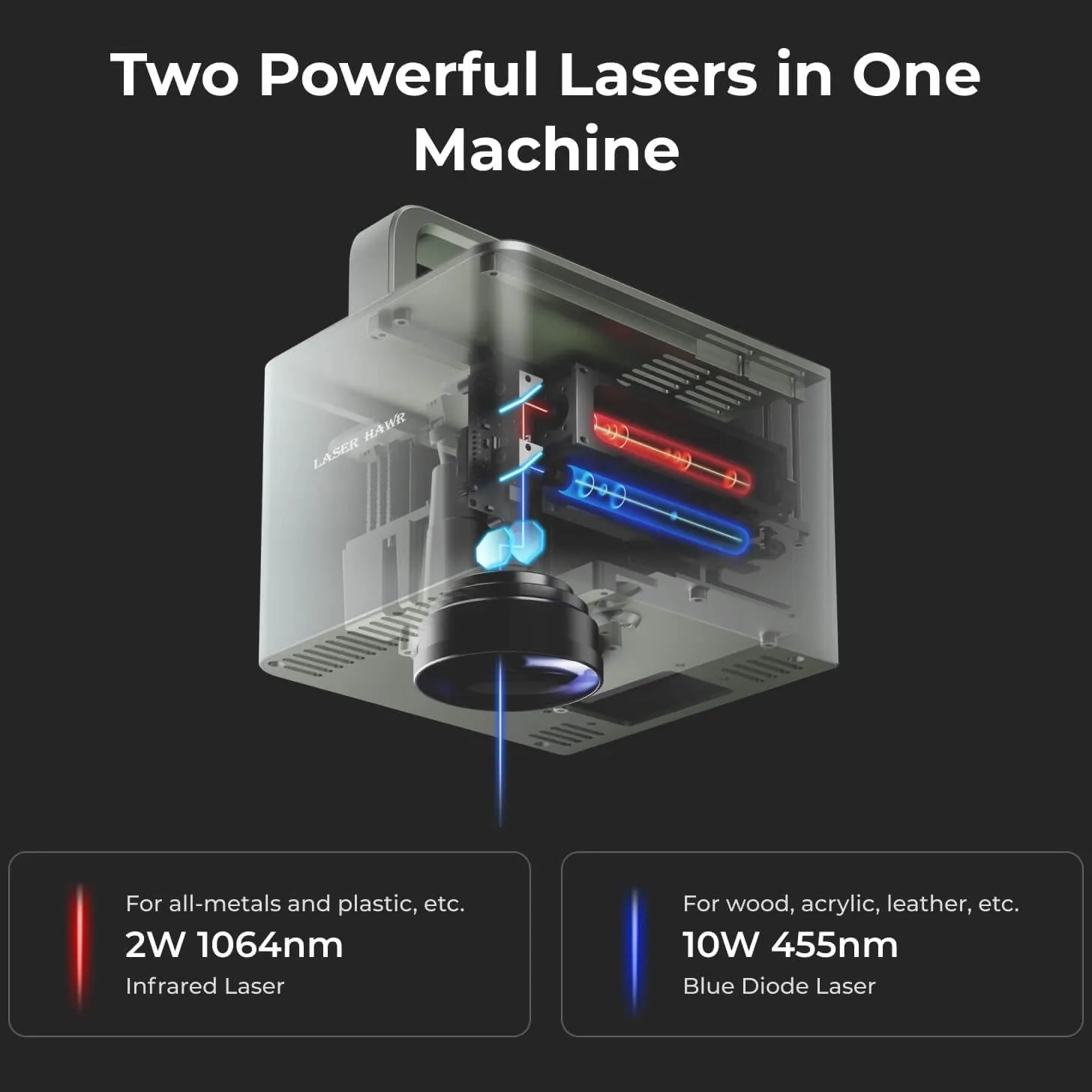

The Xtool laser engraver is a cutting-edge device that utilizes advanced laser technology to etch intricate designs, patterns, and text onto a wide range of materials. The Hawk F1 IR+DIODE model combines both infrared (IR) and diode lasers, offering unparalleled flexibility in engraving applications. Whether you’re working with metals, plastics, wood, or other surfaces, this machine delivers precise and durable markings.

Technical Specifications of the Xtool Hawk F1 IR+DIODE

Understanding the technical specifications is crucial for determining whether this laser engraver meets your needs. Below are the key details:

- Power Options: The Hawk F1 IR+DIODE operates at a maximum power of 10W, providing sufficient energy for deep engravings on tough materials.

- Laser Types: Equipped with both IR and diode lasers, this machine offers versatility in handling different materials and engraving depths.

- Engraving Area: The working area is 120mm x 60mm, allowing for detailed and precise markings on smaller projects.

- Speed: With a maximum speed of 7,000 mm/s, the Hawk F1 ensures efficient processing without compromising quality.

- Cooling System: A built-in cooling system keeps the laser head at optimal temperatures, preventing overheating and extending the machine’s lifespan.

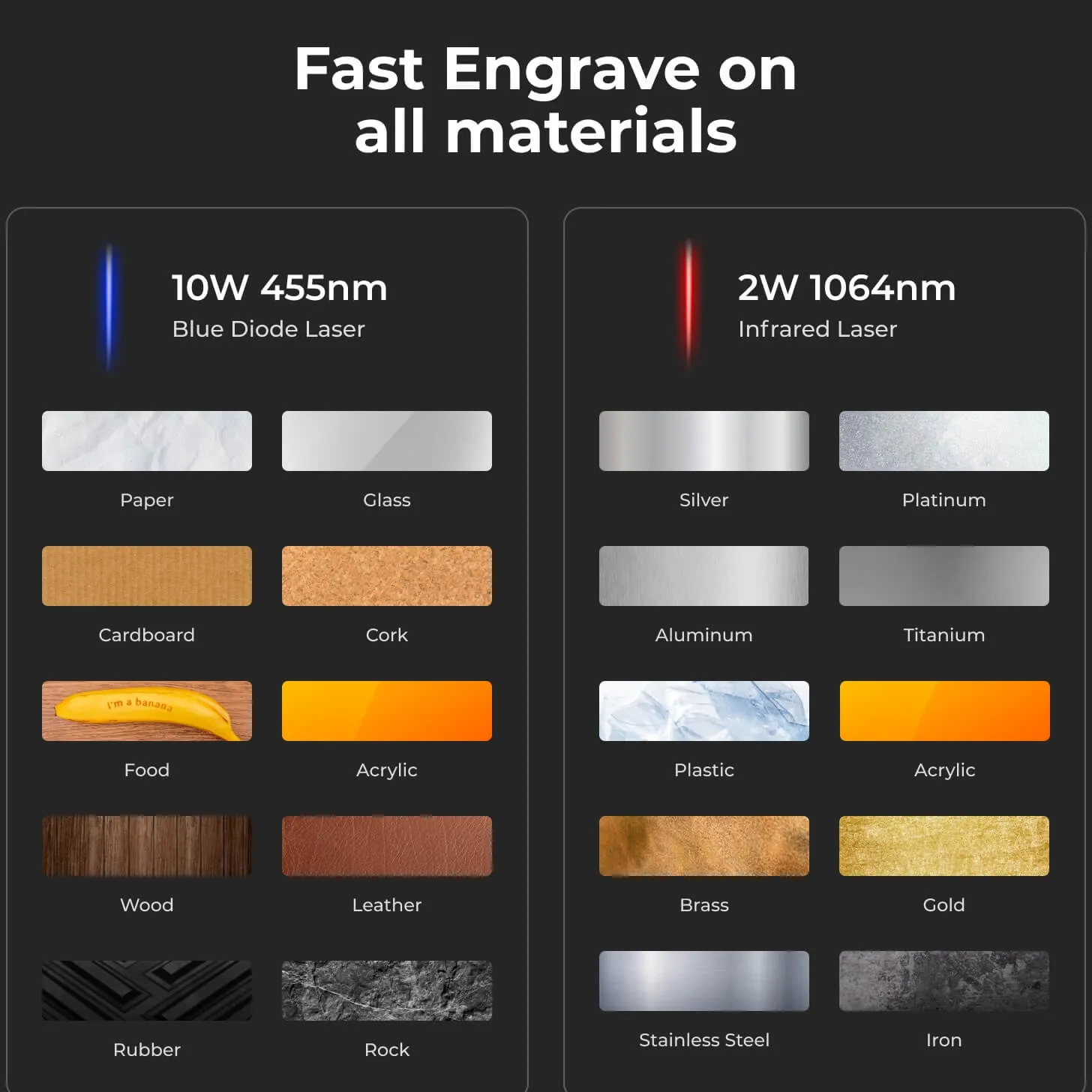

- Compatibility: The engraver supports various materials, including stainless steel, aluminum, titanium, acrylic, wood, and leather.

- Portability: Weighing only 2.5kg, this device is lightweight and portable, making it ideal for on-site operations or studio use.

These specifications make the Xtool Hawk F1 IR+DIODE a reliable choice for both hobbyists and industrial professionals.

Applications of the Xtool Laser Engraver

The versatility of the Xtool laser engraver makes it suitable for numerous applications:

- Customized Laser Marking: Create unique logos, serial numbers, or decorative patterns on products.

- Industrial Applications: Use the machine for marking components, tools, and machinery in manufacturing settings.

- CRAFTING AND ARTISTRY: Engrave intricate designs on jewelry, wooden furniture, or leather goods.

- Prototyping: prototype products with precision engravings to test designs before mass production.

Advantages of the Xtool Hawk F1 IR+DIODE

Investing in a high-quality laser engraver like the Xtool Hawk F1 IR+DIODE comes with several advantages:

- Precision and Accuracy: The dual-laser system ensures sharp and detailed engravings, even on complex designs.

- Efficiency: With its high-speed operation, this machine reduces production time while maintaining quality.

- Durability: Built to last, the Hawk F1 is designed with robust components that withstand heavy use in industrial environments.

- Versatility: The ability to switch between IR and diode lasers allows for greater adaptability across different materials and projects.

FAQ Section

1. What are the differences between IR and diode lasers?

IR (infrared) lasers are ideal for deep engravings on metal surfaces, while diode lasers are better suited for shallow markings or non-metallic materials like wood and plastic. The Hawk F1 combines both to offer maximum versatility.

2. How easy is it to maintain the Xtool laser engraver?

The machine requires minimal maintenance, with regular cleaning of the lens and ensuring adequate cooling. Xtool provides detailed guidelines for upkeep in the user manual.

3. Can I use this engraver outdoors?

Yes, thanks to its portable design, the Hawk F1 can be used in various settings, including outdoor locations. However, it’s essential to protect the device from direct sunlight and extreme temperatures.

4. What materials are compatible with the Xtool laser engraver?

The machine supports a wide range of materials, including metals (stainless steel, aluminum), plastics (acrylic), wood, leather, and glass.

5. Is training required to operate this machine?

While no formal training is necessary, familiarizing yourself with the user manual and basic laser safety protocols is recommended for optimal performance and safety.

Conclusion

The Xtool Hawk F1 IR+DIODE is a powerful addition to any workshop or industrial setting, offering precision, versatility, and reliability in laser engraving applications. Its advanced features and robust design make it a valuable tool for professionals seeking high-quality results. Whether you’re working on small-scale projects or large-scale productions, this machine delivers exceptional performance that meets the demands of modern craftsmanship.

By choosing the Xtool laser engraver, you invest in a device that combines innovation with practicality, ensuring your projects stand out with precision and elegance.

Elizabeth Bernard –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Operation and software are user-friendly. Fast speeds boost efficiency. Solid build, reliable!

Susan Martin –

★★★★★ Exceptional laser engraving quality & precision! The machine is intuitive, software user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable.

Robert Kim –

Five stars for this laser engraver! The engravings are crisp and precise. The machine is intuitive, and the software is user-friendly. Fast engraving speed boosts productivity. Solid build, highly reliable.

Jessica Davis –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. User-friendly software and smooth operation. Fast engraving speed boosts productivity. Solid build, dependable machine.

Susan Li –

Laser engraver delivers exceptional precision & detail, with intuitive software and smooth operation. High speeds boost productivity, while solid build ensures long-term reliability. 5 stars!

Daisuke Phillips (verified owner) –

**Technical Specs & Value Analysis:**

The ThunderVolt 40W CO2 laser offers a 12×8″ workspace and 1000 DPI resolution, producing sharp engravings on wood/acrylic. However, max DPI slows speed. At $2,500, it’s pricier than entry-level units but excels in durability with minimal upkeep. My boutique saw ROI in 8 months via custom jewelry (800 DPI for crisp text). Downsides: Limited Z-axis for uneven surfaces. While workspace constraints demand tiling for large projects, its precision and low maintenance justify the cost for small businesses prioritizing quality over scale.

Soo Garcia (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp results on wood, acrylic, and leather. Its precision is remarkable, capable of intricate details like fine text and delicate patterns. Speed varies depending on material thickness but remains efficient for most projects. The user experience is seamless, with an intuitive software interface that simplifies setup and design customization. A standout feature is its auto-focus system, ensuring consistent engraving quality. While it performs well in artistic applications, a minor suggestion would be to enhance cooling for extended use. Overall, this engraver offers excellent value for hobbyists and professionals alike.

Giovanni Weber (verified owner) –

The laser engraver excels in handling various materials, offering precise engravings on wood and clean cuts on acrylic. Its performance is consistent across different projects, such as detailed woodwork and intricate acrylic designs. The setup process was straightforward, though acquainting oneself with the software required some time. The interface is intuitive once mastered, featuring tools that enhance efficiency. Technically, it boasts sufficient power and resolution for high-quality work, yet larger projects may strain its workspace limits. While the engraver is versatile and efficient, minor enhancements in workspace size could expand its utility further.

Marco Rivera (verified owner) –

The laser engraver excels in User Experience with a straightforward setup process and intuitive software interface, allowing even novices to create intricate designs quickly. Its Application Scenarios are versatile, ideal for both small workshops and professional environments. It handles materials like wood and acrylic seamlessly, producing high-precision engravings. However, while its workspace is ample for most projects, additional customization options would enhance flexibility. Overall, it’s a reliable tool for artistic and business use, offering excellent value for its performance capabilities.

Jennifer Lee (verified owner) –

I absolutely love my Xtool Hawk F1 laser engraver! It’s a lifesaver for creating custom gifts—like those personalized jewelry boxes I made recently. The precision cutting makes it so easy to achieve intricate details without any hassle, and it’s surprisingly simple to use even for someone like me who’s just starting out with crafting.

Klaus Lee –

★★★★★ Exceptional laser engraving machine! The engravings are precise and stunning. The operation is smooth, software intuitive. Fast雕刻, high efficiency. Sturdy build, reliable performance.