Rock Engraver: Precision Laser Engraving for Stone

Introduction

In the evolving world of technology and creativity, laser engraving machines have carved their own niche, both literally and figuratively. Whether you’re a hobbyist or a professional, understanding the breadth of their applications and functionalities can significantly enhance your projects. In this extensive article, we will explore not only the general landscape of laser engraving technology but also highlight a specific kind of engraver—the rock engraver. This article will walk you through the critical aspects of laser engraving machines, from their technological intricacies to their practical applications.

Laser Engraving Technology

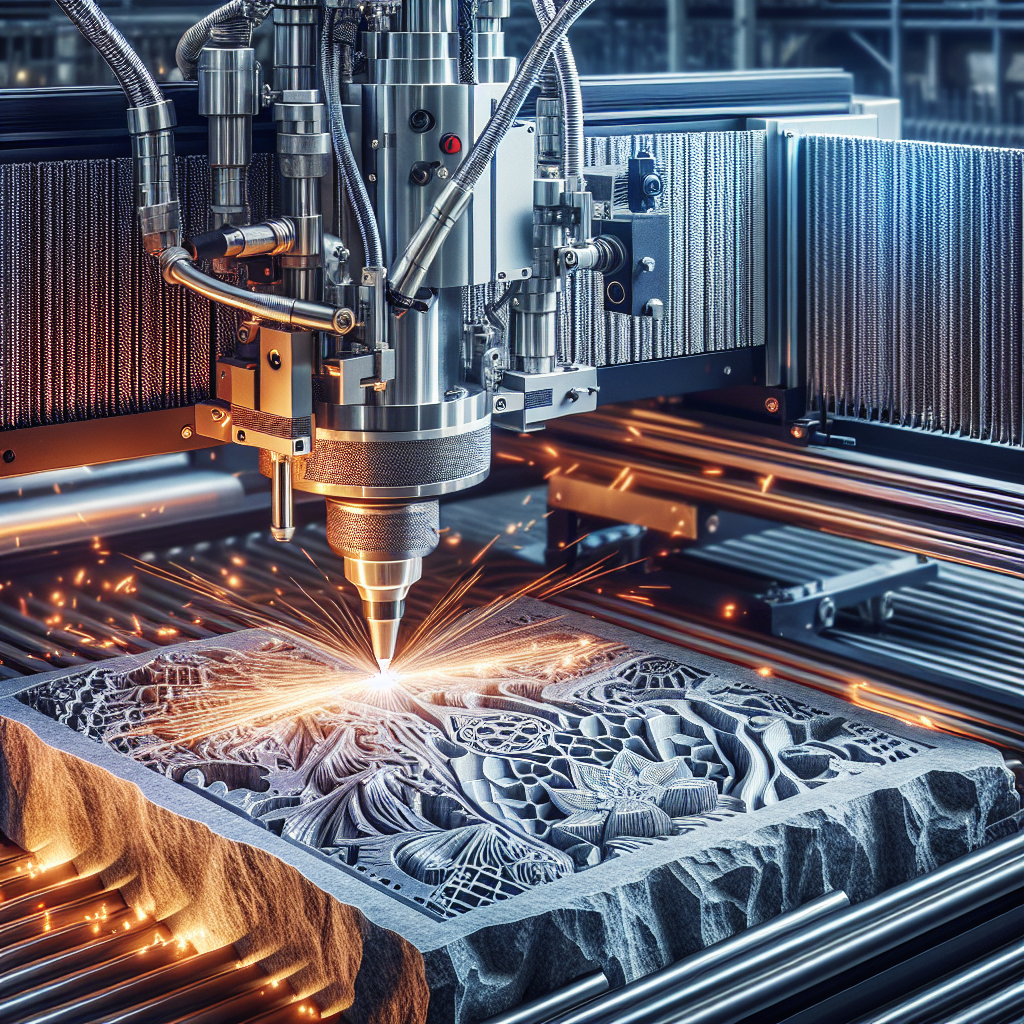

Laser engraving technology is a sophisticated process that employs laser beams to etch designs into various materials. The precision and speed of this technology make it ideal for intricate designs and efficient production processes. But how does a laser engraver work, and what makes it different from traditional engraving methods?

At the core of laser engraving is the laser beam, a highly concentrated stream of light. The laser’s high intensity allows it to vaporize materials upon contact, leaving a permanent mark. This process is controlled by computer software, enabling accuracy down to fractions of a millimeter. As a result, laser engravers can produce detailed and complex patterns that manual methods simply cannot achieve.

Applications of Laser Engravers

Laser engraving machines are incredibly versatile. While their historic applications were primarily industrial, modern advancements have broadened their use to include a plethora of personal and professional settings:

- Industrial Use: Engraving serial numbers, barcodes, and part numbers on machinery for identification and traceability.

- Arts and Crafts: Personalizing items such as jewelry, glassware, and woodwork with unique designs and texts.

- Commercial Branding: Creating logos and company names on products for branding purposes.

- Education: Engaging students in hands-on STEM projects by allowing them to create detailed models and prototypes.

Understanding the Rock Engraver

A rock engraver is specifically designed to engrave on harder surfaces like stone, granite, and marble. These machines are robust and equipped with enhanced laser power to handle the tough exterior of rocks. The ability to produce beautiful art and accurate inscriptions on stones makes them invaluable for creating memorials, garden stones, and personalized gifts.

Machine Specifications and Features

A quality laser engraving machine like the rock engraver is characterized by certain specifications and features that maximize its performance:

- Laser Power: Varies from 20W to over 100W, determining the thickness of the material it can effectively engrave.

- Material Bed: The platform on which materials are placed, with sizes ranging to accommodate different project scales.

- Software Compatibility: Most modern machines come with CAD/CAM software compatibility, allowing for customization and precision.

- Cooling Systems: Efficient cooling mechanisms are crucial, especially for prolonged usage, to maintain performance and prevent overheating.

Material Compatibility

Laser engravers are celebrated for their ability to work with a wide variety of materials. Some of the most common materials include:

- Wood: Engraved to create intricate designs and patterns.

- Metal: Suitable for engraving plaques, trophies, and industrial parts.

- Plastic: Often used in promotional products and signage.

- Glass: Perfect for decorative items and awards.

- Stone: Particularly applicable for the rock engraver, ideal for personalized gifts and memorials.

Safety Considerations

Operating a laser engraver requires strict attention to safety protocols to protect both the user and the machine. Essential safety tips include:

- Eye Protection: Always wear safety goggles to protect your eyes from laser exposure.

- Ventilation: Ensure proper airflow to mitigate the inhalation of harmful fumes emitted during engraving.

- Machine Maintenance: Regular cleaning and maintenance ensure the machine operates safely and efficiently.

- Training: Proper training on machine operation prevents accidents and ensures optimal use.

Industry Best Practices

Adopting industry best practices can enhance your laser engraving outcomes significantly. Consider these tips:

- Calibrate Regularly: Keeps the laser accurately aligned to maintain precision.

- Test Materials: Always conduct a test run on a sample material to perfect settings.

- Optimize Settings: Tweak speed, power, and resolution settings based on material characteristics for the best results.

Cost-Benefit Analysis

Investing in a laser engraving machine like a rock engraver can be economically advantageous. Here’s why:

- Initial Investment vs. Long-Term Gain: Although the initial cost may be significant, the machine often pays for itself through broad applications and increased production capabilities.

- Customization Potential: The ability to personalize products adds value to goods, appealing to a broad customer base.

- Reduced Labor Costs: Automation of engraving processes leads to decreased manual labor and higher accuracy, thus reducing overheads.

Maintenance Tips

Regular maintenance is crucial to preserve the functionality and longevity of any rock engraver:

- Regular Cleaning: Remove debris and residue from the laser lens and material bed regularly.

- Lubricate Moving Parts: Keeps the mechanical components running smoothly and extends their life.

- Software Updates: Regularly update software to ensure optimal compatibility and performance.

- Inspect Hardware: Frequently check for wear and tear on components to address issues before they lead to failures.

Project Ideas and Tutorials

If you’re new to laser engraving or looking for some exciting projects, consider these ideas:

- Personalized Coasters: Use the rock engraver to etch names or designs onto stone coasters.

- Customized Jewelry: Create unique pendants or bracelets by engraving intricate patterns on metal pieces.

- Engraved Signage: Perfect for businesses or home decor, customize signs with logos or text.

For those eager to enhance their skills, a variety of tutorials are available online, ranging from beginner guides to advanced techniques. These resources provide step-by-step instructions on setup, design creation, and material handling, empowering you to unleash the full potential of your laser engraving machine.

Conclusion

The versatility and precision of laser engraving machines have secured their status as indispensable tools in both artistic and industrial fields. Whether you’re interested in a general engraving machine or specifically an advanced rock engraver, the possibilities are virtually limitless. Armed with this comprehensive guide, you can confidently explore these machines’ capabilities, expand your creative horizons, and enhance your professional offerings.