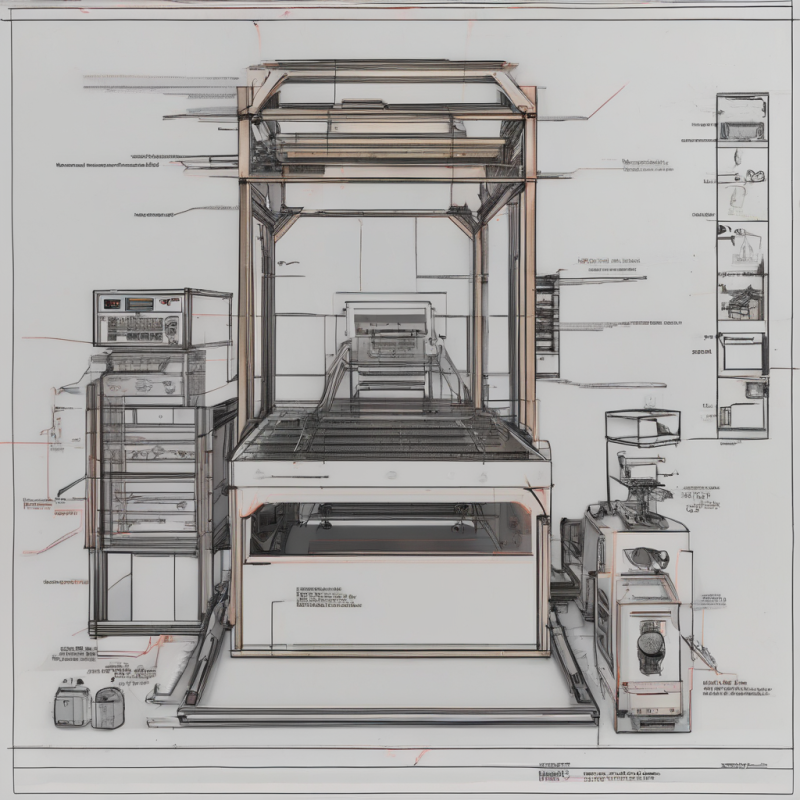

The Best Laser Cutter for Beginners: A Comprehensive Guide

Welcome to our guide on finding the best laser cutter for beginners! If you’re new to the world of laser cutting, you might be overwhelmed by the sheer number of options available. However, with the right guidance and tools, you can master this exciting technology in no time. In this article, we’ll explore everything you need to know about choosing a laser cutter that’s perfect for beginners, including features, safety considerations, and maintenance tips.

Why Choose a Laser Cutter for Beginners?

Laser cutting is a versatile and precise tool that can be used for a wide range of projects, from engraving wood to creating intricate designs on metal. For beginners, a laser cutter offers an accessible way to dive into the world of DIY projects, crafting, and even small-scale manufacturing. But with so many options available, how do you choose the right one? That’s where the **** comes in.

Before we dive into the details, let’s address a common question: What makes a laser cutter suitable for beginners? The answer lies in simplicity, safety, and ease of use. A good beginner-friendly laser cutter should have an intuitive interface, minimal setup requirements, and robust safety features to ensure you can start creating without worrying about complex controls or potential hazards.

Key Features to Look For in a Laser Cutter

When selecting the best laser cutter for beginners, there are several key features to consider. These include:

- Laser Power: The power of the laser determines what materials you can cut or engrave. A lower-powered laser is sufficient for softer materials like wood, plastic, and leather, while higher-powered lasers are needed for metals.

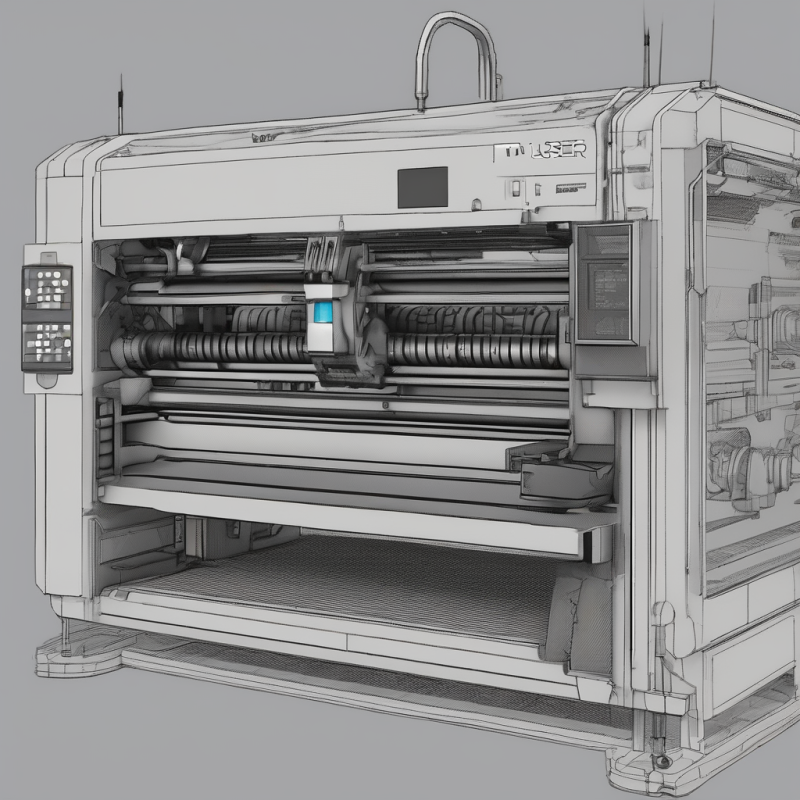

- Build Quality: A well-constructed laser cutter will last longer and provide more consistent results. Look for models with durable frames, high-quality optics, and reliable cooling systems.

- User Interface: An easy-to-use interface is crucial for beginners. Touchscreens, simple controls, and pre-programmed settings can make the learning curve much smoother.

- Software Compatibility: Most laser cutters come with software that allows you to design and control your projects. Ensure the software is user-friendly and compatible with your operating system.

- Safety Features: Safety should always be a top priority. Look for features like emergency stop buttons, automatic shutdowns, and built-in safety sensors.

Now that we’ve covered the key features, let’s take a closer look at why the **** stands out as an excellent choice.

Why This Laser Cutter Stands Out

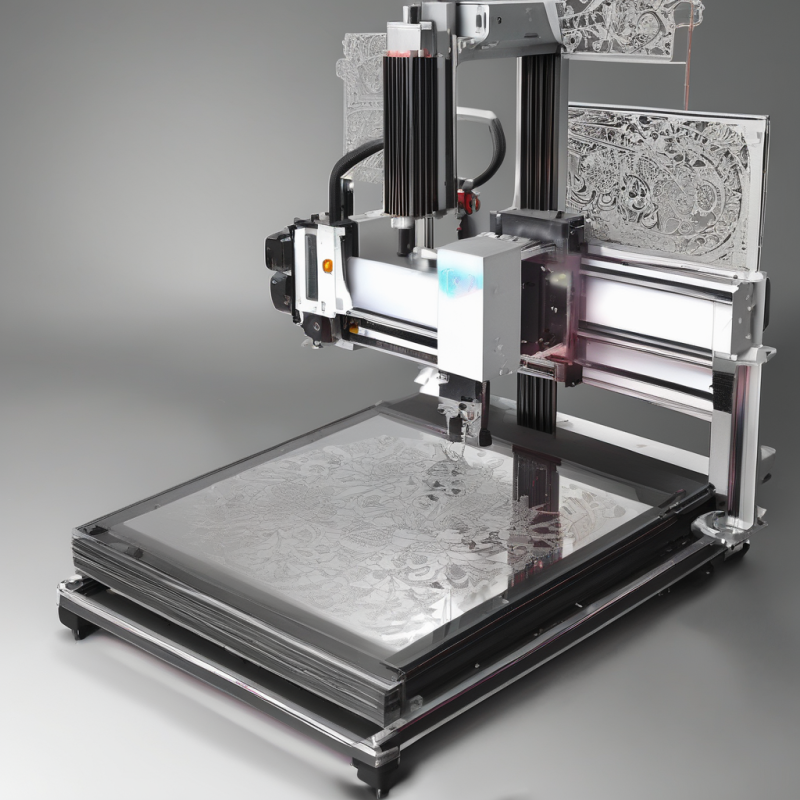

The **** is designed with simplicity in mind, making it an ideal choice for those new to laser cutting. Here are some of its standout features:

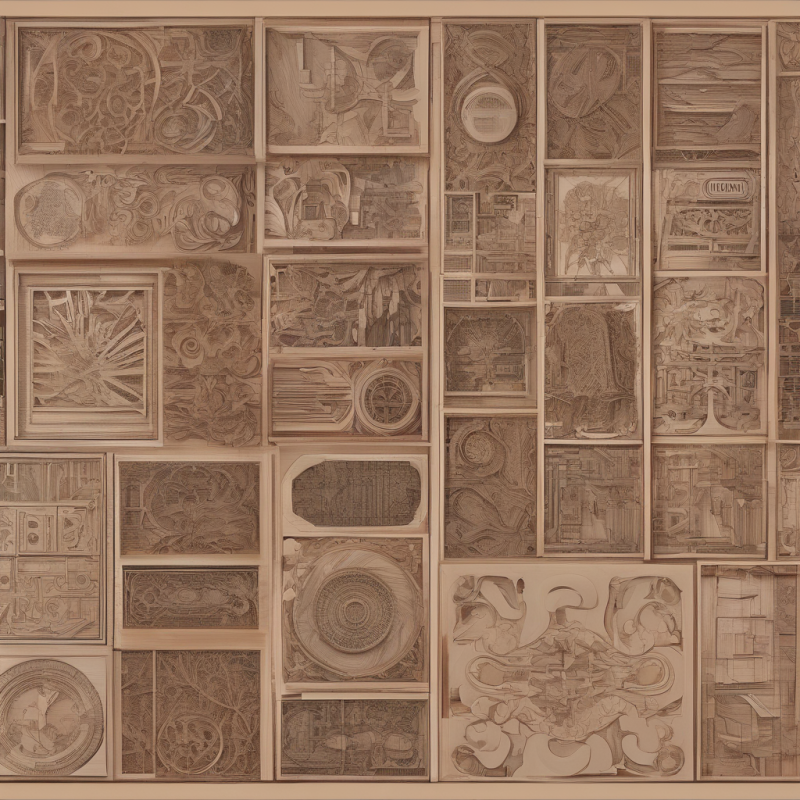

- High-Quality Engraving: This laser cutter produces crisp and detailed engravings on a variety of materials, including wood, plastic, and leather.

- User-Friendly Interface: With an intuitive touchscreen interface, even those with no prior experience can navigate the settings and controls effortlessly.

- Versatile Software: The included software is compatible with popular design programs like Adobe Illustrator and CorelDRAW, allowing you to create custom designs from scratch or import existing files.

- Compact Design: This laser cutter has a compact footprint, making it perfect for small workshops or home use.

- Safety Features: Equipped with emergency stop buttons and automatic shutdowns, this machine prioritizes user safety at all times.

One of the most common questions we receive is: How does this laser cutter compare to other models on the market? The answer lies in its balance of affordability, performance, and ease of use. While more advanced models may offer additional features like higher power levels or larger cutting areas, they often come at a much higher price point and require more technical expertise to operate.

Tips for Getting Started with Laser Cutting

Now that you’ve chosen your laser cutter, it’s time to start creating! Here are some tips to help you get the most out of your machine:

- Familiarize Yourself with the Controls: Take the time to read the manual and explore all the features of your laser cutter. Understanding how each control works will give you more confidence as you begin your projects.

- Start Small: Begin with simple designs and small-scale projects to get a feel for the machine’s capabilities. This will also help you learn how different materials react to the laser beam.

- Experiment with Materials: Don’t be afraid to try out different materials like wood, plastic, and metal. Each material behaves differently under the laser, so experimenting will give you a better understanding of what’s possible.

- Maintain Your Machine: Regular maintenance is essential for ensuring your laser cutter continues to perform at its best. Clean the optics regularly, check the belts and pulleys for wear, and ensure all safety features are functioning properly.

Another frequently asked question is: What are some good project ideas for beginners? The possibilities are endless! You can start with something as simple as engraving a name on a wooden plaque or creating decorative designs on leather goods. As you gain more experience, you can move on to more complex projects like cutting intricate patterns in metal or creating 3D objects.

Safety First: Best Practices for Laser Cutting

While laser cutters are generally safe when used correctly, it’s important to follow best practices to minimize risks. Here are some safety tips to keep in mind:

- Always Wear Protective Gear: Protect your eyes with safety goggles and wear gloves to prevent burns from hot materials.

- Ventilate Your Workspace: Laser cutting can produce fumes, so ensure your workspace is well-ventilated or use a fume extraction system.

- Avoid Flammable Materials: Never cut or engrave materials that are highly flammable or explosive, as this can create dangerous situations.

- Follow Manufacturer Guidelines: Always adhere to the safety instructions provided in your machine’s manual and avoid modifying the equipment unless instructed to do so.

By following these guidelines, you can enjoy a safe and rewarding experience with your laser cutter. Remember, practice makes perfect! The more you use your machine, the more comfortable and confident you’ll become in its operation.

Maintenance and Troubleshooting

To keep your laser cutter running smoothly, regular maintenance is essential. Here are some steps you can take to ensure your machine stays in top condition:

- Clean the Optics: Dirt and dust can interfere with the performance of your laser cutter’s optics. Use a soft cloth or lens cleaner to keep them clean.

- Inspect Belts and Pulleys: Over time, belts and pulleys can wear out or become misaligned. Regularly check for signs of wear and replace them as needed.

- Check the Cooling System: A well-functioning cooling system is crucial for preventing overheating. Ensure the fans are working properly and clean any dust buildup from the vents.

- Calibrate the Machine: Periodically check the alignment of your laser cutter to ensure accurate cuts and engravings.

If you encounter any issues with your machine, consult the manual or reach out to customer support for assistance. Common problems like misalignment or malfunctioning sensors can often be resolved with a quick adjustment or cleaning.

Frequently Asked Questions

Before we wrap up, let’s address some of the most frequently asked questions about laser cutters:

- Q: Can I use this laser cutter for metal? A: Yes, but it depends on the power level of your machine. The **** is suitable for softer materials like wood and plastic. For cutting metal, you’ll need a higher-powered laser.

- Q: Is this machine easy to set up? A: Absolutely! The setup process is straightforward and can be completed in just a few minutes with the included instructions.

- Q: How long does it take to learn how to use a laser cutter? A: It depends on your experience level, but most people can start creating simple projects within a couple of hours.

- Q: Can I cut thick materials with this machine? A: The thickness you can cut will depend on the power and specifications of your laser cutter. Always consult the manual for guidelines on material thickness.

We hope these answers have helped clarify any questions you may have had about laser cutters. If you’re still unsure about anything, don’t hesitate to reach out to the manufacturer or a professional for advice.

Conclusion

Owning a laser cutter opens up a world of creative possibilities! Whether you’re a hobbyist looking to try your hand at crafting or a professional in need of precision cutting tools, this machine is sure to become an invaluable addition to your workshop. With proper care and attention, your laser cutter will provide years of reliable service and allow you to bring your projects to life with ease.

Remember, the key to success with any new tool is practice and experimentation. Don’t be afraid to try out different materials, techniques, and designs as you explore the capabilities of your laser cutter. With time and experience, you’ll develop the skills needed to create stunning works of art and functional items alike.

If you’re ready to take the plunge into the world of laser cutting, we highly recommend giving the **** a try. Its user-friendly design and versatile capabilities make it an excellent choice for anyone looking to get started with this exciting technology.

Happy creating!

Certainly! Here’s a step-by-step guide on how to use the best laser cutter for beginners, including safety precautions:

Step 1: Familiarize Yourself with the Machine

– **Read the Manual:** Start by understanding the machine’s features and controls through its manual.

– **Inspect Components:** Check all parts like the laser head, work area, control panel, and power supply.

Step 2: Set Up Your Workspace

– **Choose a Location:** Place your laser cutter in a well-ventilated area to avoid inhaling fumes. Ensure it’s on a stable surface.

– **Prepare Tools:** Gather necessary materials like protective eyewear, gloves, masks, cleaning tools, and work clamps.

Step 3: Prepare Your Project

– **Design Your Cut:** Use laser cutting software (e.g., CorelDRAW, Adobe Illustrator) to create or import your design. Save it as a compatible file type.

– **Select Materials:** Choose materials like wood, acrylic, leather, or fabric based on the project and machine specifications.

Step 4: Set Up the Machine

– **Adjust Settings:** Use the control panel to set parameters such as laser speed, power, and focus according to your material and design.

– **Load Material:** Securely place your material on the work area using clamps or tape. Ensure it’s flat and aligned.

Step 5: Perform a Test Cut

– **Run a Trial:** Execute a small test cut to check settings and ensure accuracy. Adjust as needed for optimal results.

Step 6: Execute Your Project

– **Start Cutting:** Once satisfied with the test, begin your main project. Monitor the process, especially if working on unfamiliar materials.

– **Handle Fumes:** Use ventilation or an extraction system to manage fumes from cutting.

Step 7: Post-Cut Actions

– **Turn Off the Machine:** After finishing, switch off the laser and unplug it for safety.

– **Clean Up:** Remove your workpiece and clean the machine, especially the lens and work area, to maintain performance.

Step 8: Safety Precautions

– **Wear Protective Gear:** Always use goggles, gloves, and masks to protect against dust and heat.

– **Ventilate Properly:** Ensure good airflow to avoid inhaling harmful fumes.

– **Follow Manufacturer Guidelines:** Adhere strictly to the manual’s instructions for safe operation.

By following these steps and prioritizing safety, you can efficiently use your laser cutter and create high-quality projects.