The Comprehensive Guide to Laser Cutter Engravers

Introduction

The world of laser technology is vast, dynamic, and full of potential. Laser engraving machines are at the forefront of this technological revolution. With tools like the laser cutter engraver, industries from arts and crafts to high-tech manufacturing are transforming how they create and innovate. In this article, we’ll delve deep into the capabilities, features, and applications of laser engraving machines and why they are essential tools in modern creative and production processes.

Laser Engraving Technology and Applications

Laser engraving is a process that uses a laser cutter engraver to vaporize materials, creating precise and permanent markings on various surfaces. This technology boasts a wide range of applications, including:

- Custom Artwork: Creatives in the arts sector utilize laser engravers to personalize designs on wood, glass, and metal.

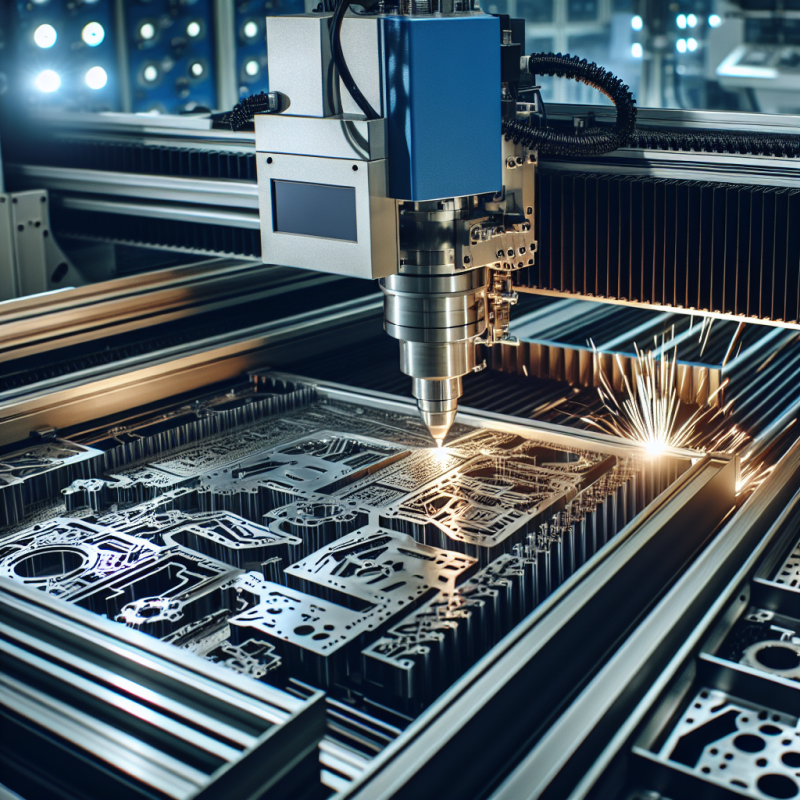

- Industrial Manufacturing: Laser engraving is crucial for part marking and branding in industries like automotive and aerospace.

- Jewelry Design: Intricate designs and personalizations are made possible with precision laser engraving on precious metals.

- Electronics: Engraving circuit boards and components for identification and traceability.

- Monogramming: Personal items such as leather wallets and notebooks can be engraved with initials or designs.

The versatility of laser engraving machines ensures that they serve an integral role across multiple disciplines.

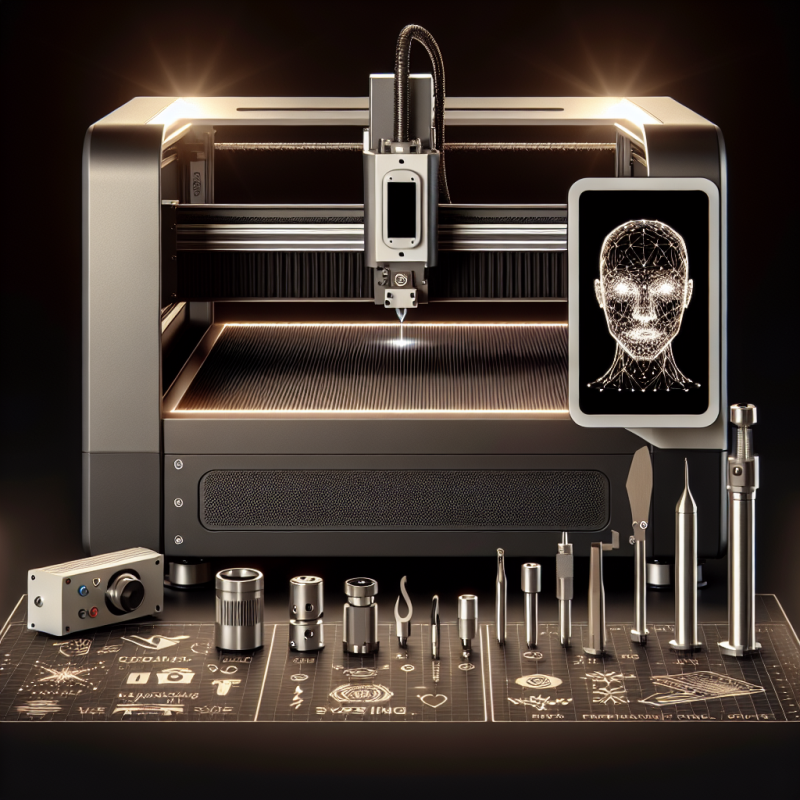

Machine Specifications and Features

Understanding the technical specifications and features of a laser cutter engraver is critical for choosing the right machine for your needs. Key features include:

- Laser Power: This is measured in watts and dictates the cutting and engraving capacity of the machine.

- Engraving Speed: The speed at which the laser moves across the material affects productivity and detail.

- Resolution: Measured in dots per inch (DPI), it determines the precision and detail of the engraving.

- Software Compatibility: Modern laser engravers are compatible with various design software, enhancing their usability.

- Connectivity: USB and wireless capabilities improve integration within existing workflows.

Each of these features adds value and function, making the laser cutter engraver Laserpecker LX1 Series a top choice for professionals.

Material Compatibility

A major advantage of using a laser cutter engraver is its material compatibility. These machines can engrave and cut through a wide array of materials:

- Wood: From soft balsa to hardwoods, offering versatile cutting and engraving options.

- Metal: Certain laser engravers can mark metals or polish surfaces for a shiny effect.

- Plastics: Often used for creating detailed plaques or industrial components.

- Fabric: Creating intricate designs for fashion purposes.

- Glass: Custom etching on bottles and glassware.

The ability to work with multiple materials makes laser engraving machines indispensable in multiple crafts and industries.

Safety Considerations

Using a laser cutter engraver requires adherence to specific safety protocols. Here are essential considerations:

- Protective Gear: At a minimum, users should wear protective eyewear to shield against laser glare.

- Ventilation: Ensure proper exhaust systems are in place to avoid inhalation of fumes from materials.

- Emergency Shutoff: Machines should have prominent emergency stops to quickly halt operations if needed.

Understanding and implementing these safety measures protect operators from potential hazards.

Industry Best Practices

Professionals using a laser cutter engraver should follow industry best practices to optimize performance:

- Regular Calibration: Frequently calibrating the machine ensures precision and prolongs its operational life.

- Material Testing: Engraving on a sample piece first determines suitable settings for new materials.

- Software Updates: Keeping your software updated ensures access to the latest features and fixes.

Adhering to these best practices can markedly enhance the engraving process’s efficiency and output quality.

Cost-Benefit Analysis

Investing in a laser cutter engraver involves a comprehensive cost-benefit analysis. While the initial cost may be significant, the long-term benefits include:

- Efficiency Gains: Faster production times that lead to increased throughput.

- Customization Capabilities: The ability to offer unique designs increases customer satisfaction and market differentiation.

- Durability: High-quality laser engravers have long operational lives, ensuring returns on investment.

The analysis should factor in projected savings from enhanced efficiencies against initial setup costs.

Maintenance Tips

Proper maintenance prolongs the life of a laser cutter engraver. Effective maintenance practices include:

- Regular Cleaning: Clean lenses and mirrors to maintain laser efficiency.

- Lubrication: Apply lubricant to moving parts to reduce wear and ensure smooth operation.

- Alignment Checks: Regularly check laser alignment to prevent inaccuracies.

Consistent maintenance reduces downtimes and the likelihood of costly repairs, ensuring smooth and effective production.

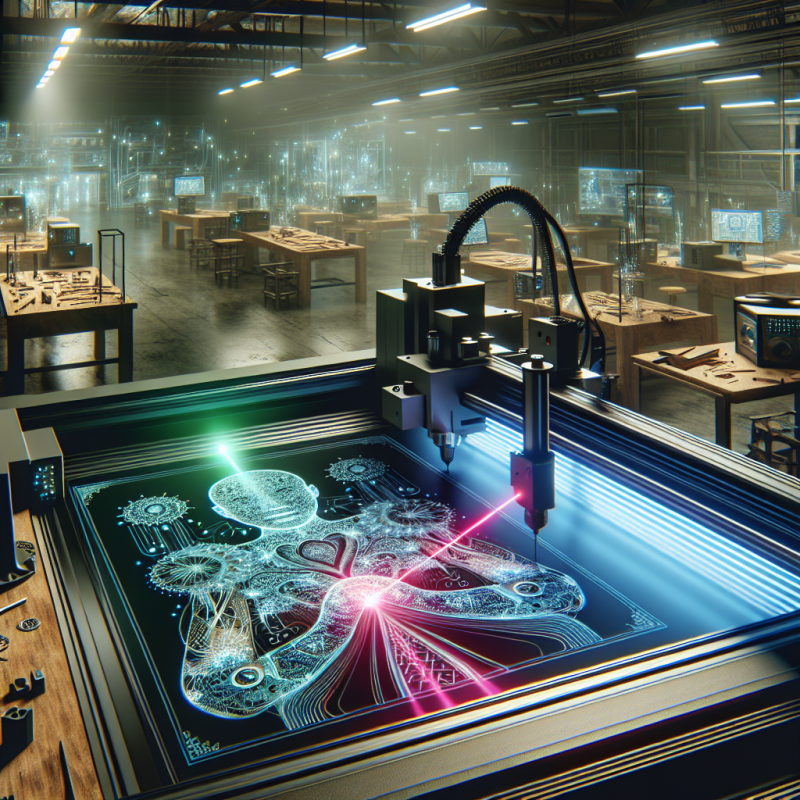

Project Ideas and Tutorials

For those looking to explore creative uses of a laser cutter engraver, consider these project ideas:

- Personalized Gifts: Create custom jewelry or engraved portraits for loved ones.

- Home Décor: Develop intricate wall art or engraved mirrors.

- Prototyping: Use laser cutting for quick and precise product prototype development.

- Educational Tools: Make educational models and kits for interactive learning experiences.

Whether for personal enjoyment or entrepreneurial endeavors, these projects exemplify the diverse potential of laser engraving technology.

Conclusion

In conclusion, the adoption of a laser cutter engraver heralds a new era of precision, efficiency, and innovation in design and manufacturing. This powerful technology empowers creators to push the boundaries of what’s possible, rendering it an indispensable asset across industries. By understanding its features, safe usage, and maintenance, users can fully harness the potential of laser engraving machines—a true testament to the synergy of creativity and technology.