The Evolution and Applications of CNC Laser Cutting and Engraving Machines

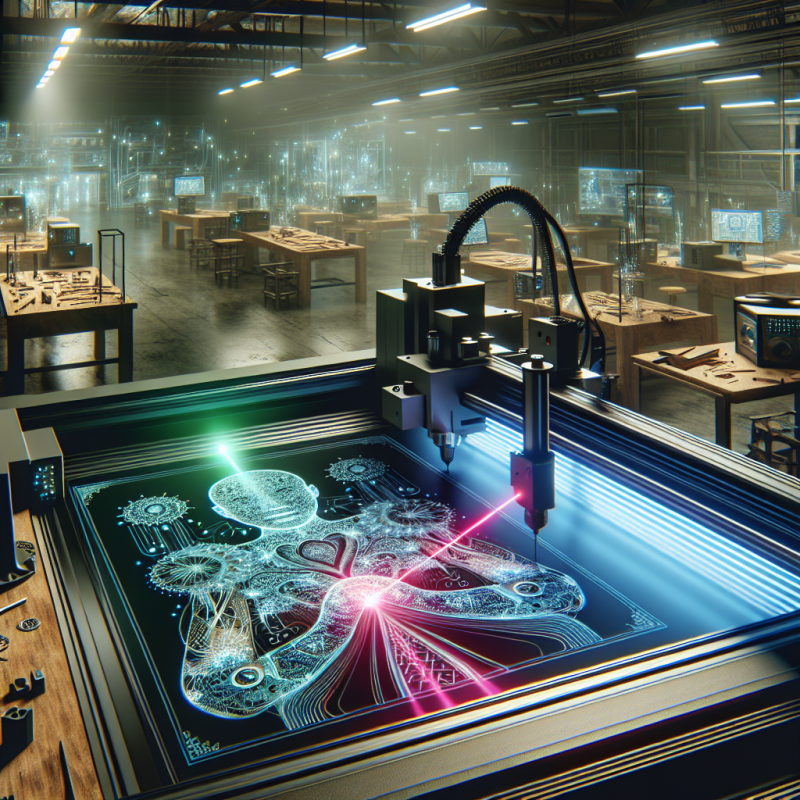

In the ever-evolving world of manufacturing and creative design, cnc or laser cutter machines have emerged as revolutionary tools. Combining precision, speed, and versatility, these devices are transforming industries ranging from aerospace to handicrafts. This article explores the technology behind CNC laser cutting and engraving systems, their applications, and why they are indispensable in modern workflows.

Understanding CNC and Laser Cutting Technology

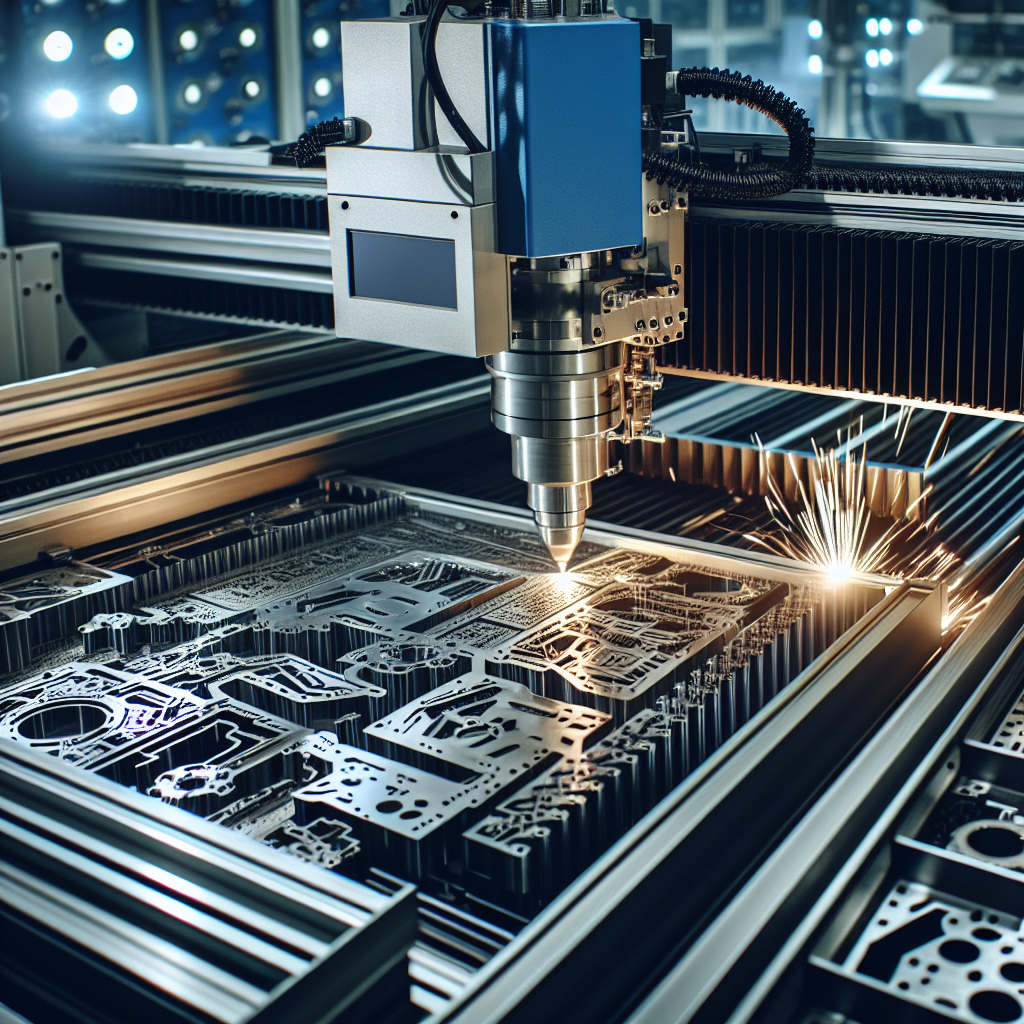

At their core, cnc or laser cutter machines rely on two fundamental components: Computer Numerical Control (CNC) systems and high-powered lasers. The CNC system translates digital designs into precise mechanical movements, while the laser beam cuts or engraves materials with micron-level accuracy. What makes this combination so powerful? It eliminates human error, ensures repeatability, and handles complex geometries that traditional tools cannot.

Key Advantages of Laser Engraving Machines

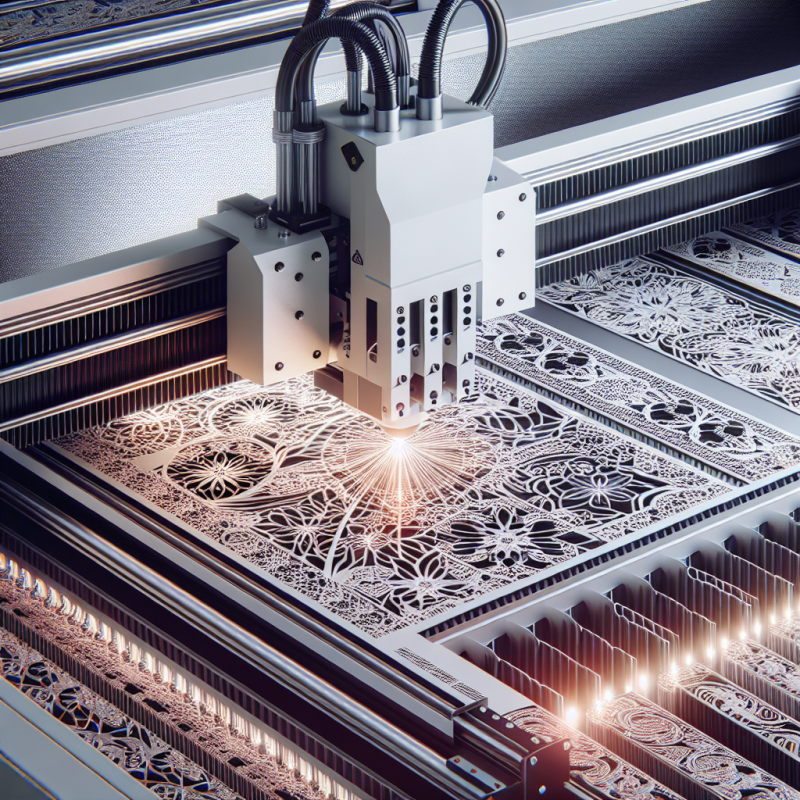

Precision is the hallmark of cnc or laser cutter systems. Unlike manual methods, lasers produce crisp edges and intricate details on materials like wood, metal, glass, and acrylic. Additionally, these machines offer:

- Speed: Complete projects in minutes instead of hours.

- Versatility: Switch between cutting and engraving modes effortlessly.

- Scalability: Perfect for both small prototypes and mass production.

Moreover, modern cnc or laser cutter devices integrate user-friendly software, making them accessible even to non-experts. But how do you choose the right machine for your needs?

Applications Across Industries

The adaptability of cnc or laser cutter technology has led to its adoption in diverse sectors:

- Manufacturing: Cutting metal components for automotive or aerospace use.

- Art and Design: Creating detailed engravings on jewelry or custom signage.

- Healthcare: Producing medical devices with sterile, high-precision edges.

- Education: Teaching students about digital fabrication and prototyping.

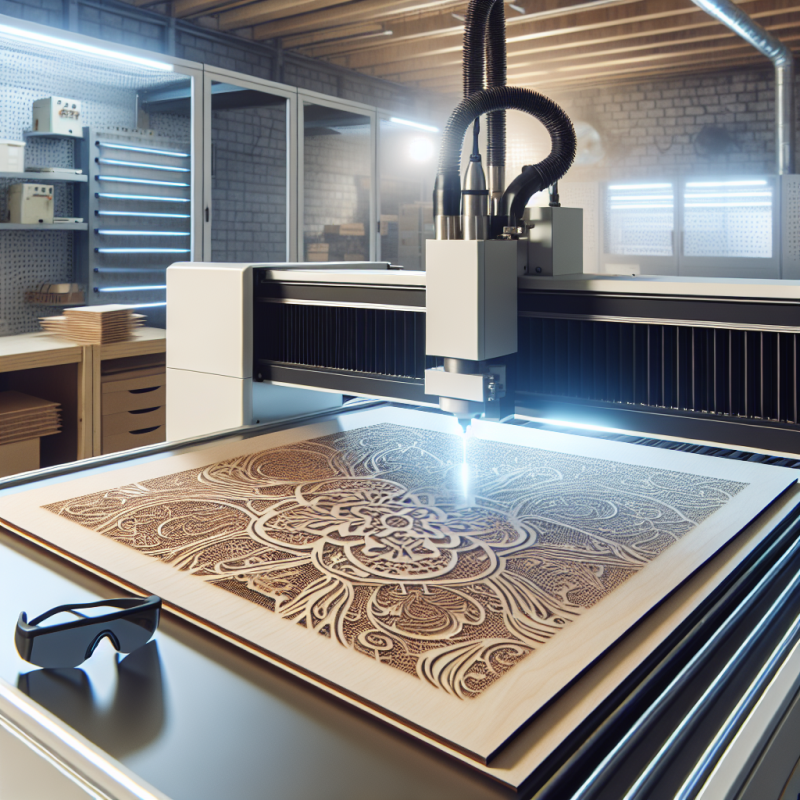

Did you know? Many startups now use laser engraving machines to personalize products, from phone cases to wooden furniture, tapping into the growing demand for bespoke items.

Choosing the Right CNC Laser Machine

Selecting a cnc or laser cutter requires careful consideration of factors like power, bed size, and material compatibility. For instance, a 40W CO2 laser might suffice for engraving wood, but cutting thick metals demands a fiber laser with higher wattage. Key questions to ask include:

- What materials will I work with most frequently?

- Do I need dual functionality (cutting and engraving)?

- Is the software compatible with my existing design tools?

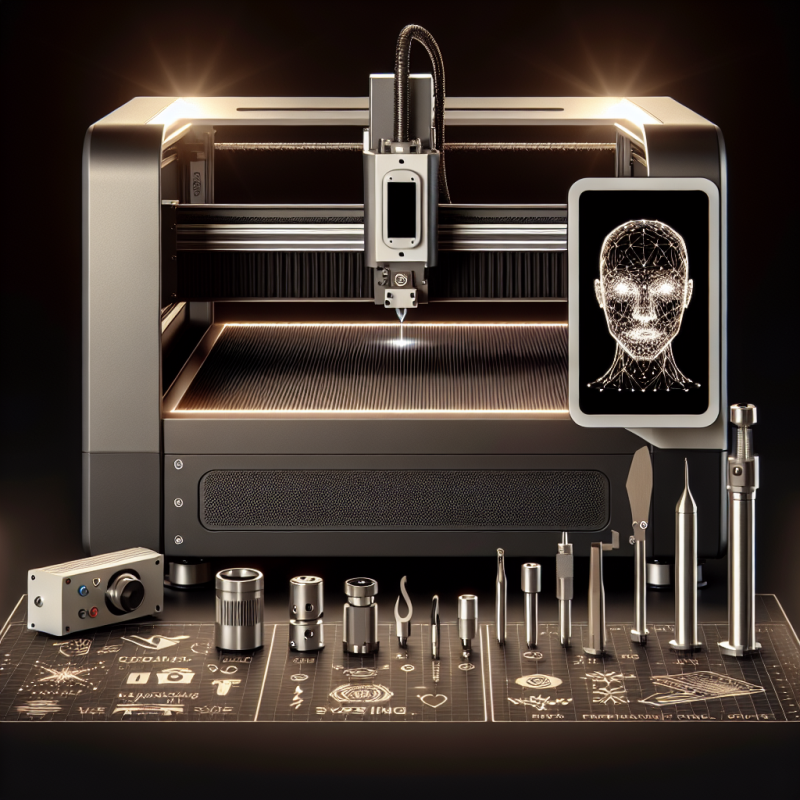

Investing in a machine like the Hawk S1 CNC Laser Cutter ensures reliability and advanced features, such as autofocus and real-time monitoring.

Maintenance and Safety Best Practices

To maximize the lifespan of your cnc or laser cutter, regular maintenance is critical. Clean lenses and mirrors weekly to prevent beam distortion, and check alignment after intensive use. Safety cannot be overstated: always wear protective eyewear and ensure proper ventilation to avoid inhaling fumes. What common mistakes do operators make? Neglecting calibration or using incorrect settings for materials, which leads to subpar results or machine damage.

The Future of Laser Cutting Technology

Innovation in cnc or laser cutter systems continues to accelerate. Emerging trends include AI-driven optimization, faster processing speeds, and hybrid machines that combine additive and subtractive manufacturing. As sustainability gains importance, energy-efficient lasers and recyclable material compatibility are becoming key selling points. The future is bright for businesses leveraging these advancements to stay competitive.

Frequently Asked Questions

Q: Can laser cutters handle reflective materials like brass or copper?

A: Yes, but fiber lasers are recommended for metals, whereas CO2 lasers struggle with reflections.

Q: How much training is needed to operate a CNC laser machine?

A: Basic operations can be learned in a day, but mastering advanced techniques may take weeks.

Q: What’s the average cost of a mid-range laser engraver?

A: Prices range from $3,000 to $10,000, depending on power and features.

In conclusion, cnc or laser cutter machines are indispensable tools for modern creators and manufacturers. By understanding their capabilities and staying updated on trends, users can unlock endless possibilities in precision engineering and artistic expression.