The Revolutionary World of Laser Cutter and Engraver

Introduction

In the ever-evolving landscape of technology, laser cutter and engraver machines have emerged as critical tools for both hobbyists and professionals alike. From intricate designs on wood to precise etchings on metal, these machines have broadened horizons in creative and industrial fields. This article aims to provide an in-depth look at the world of laser engraving machines, focusing on their technology, applications, and benefits.

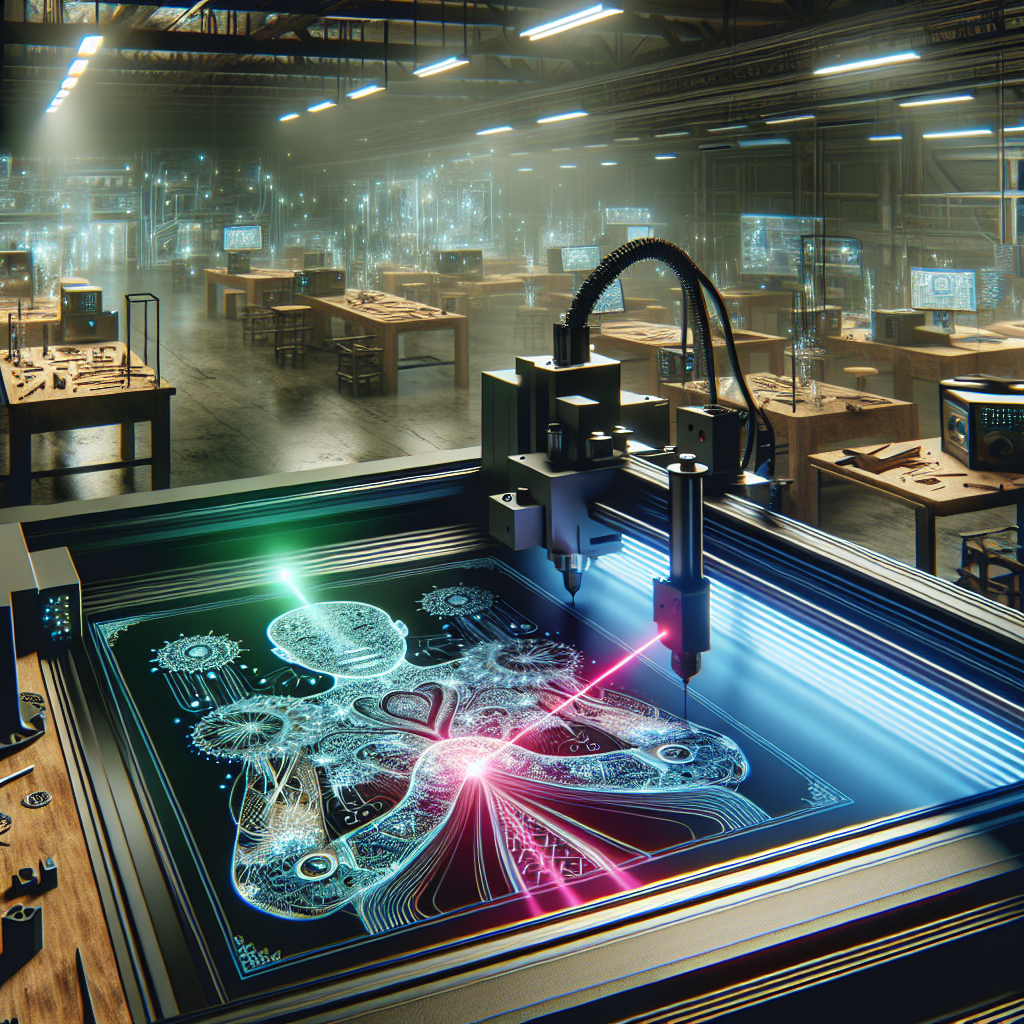

Laser Engraving Technology and Applications

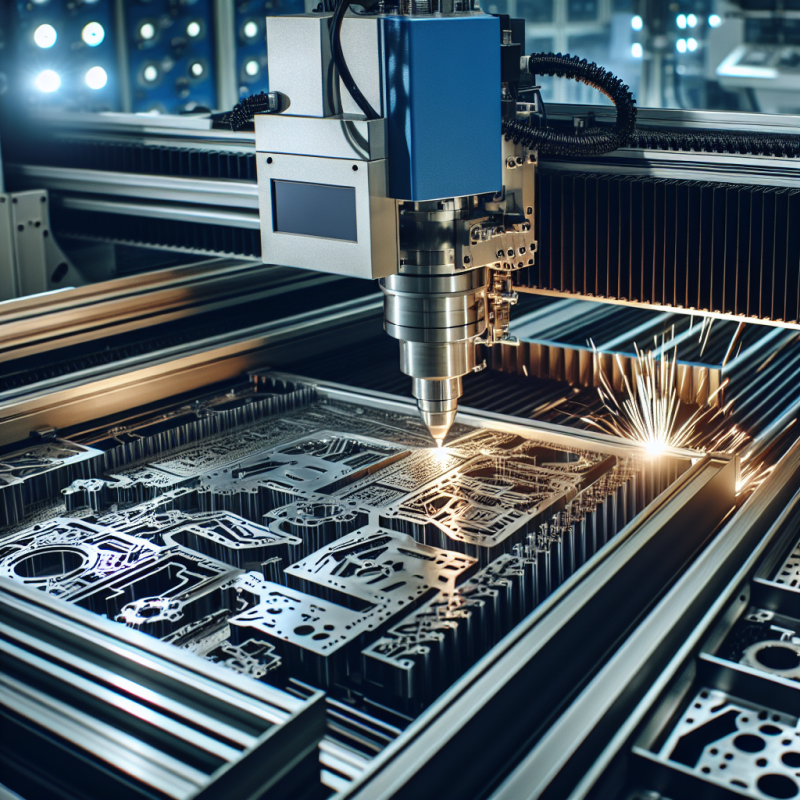

Laser engraving technology works by directing a high-powered laser beam onto a material, to either cut or engrave it. The precision that a laser cutter and engraver provides is unmatched, allowing for detailed designs and efficient processing. This technology is widely used in industries such as automotive, aerospace, jewelry, and signage.

Applications extend beyond industrial uses; artists and artisans utilize laser cutter and engraver machines for creating beautiful custom pieces. Whether it’s for prototyping or full-scale production, laser engravers offer flexibility and precision that other tools simply can’t match.

Machine Specifications and Features

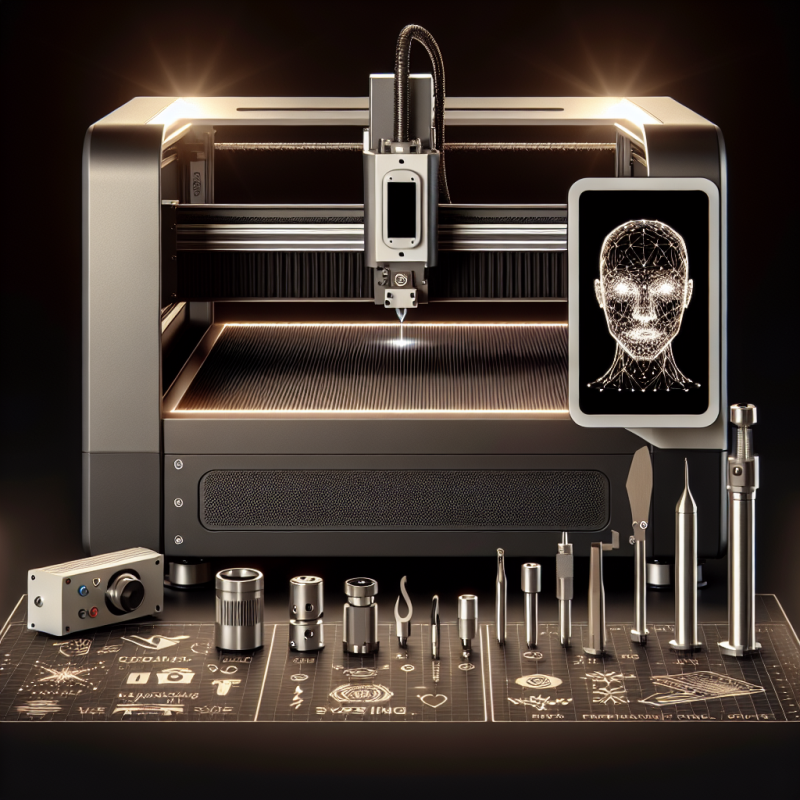

Modern laser engraving machines like the Xtool S1 Enclosed Diode Laser Cutter come equipped with advanced features and specifications aimed at enhancing user experience and work quality. Key attributes include adjustable laser power, high precision focusing, and versatile material compatibility.

When it comes to specifications, factors such as laser power, working area size, and software compatibility must be considered. Machines with higher laser power offer faster processing speeds and the ability to work on tougher materials. The inclusion of intuitive software enhances the ease of operation, ensuring even beginners can start with minimal training.

Material Compatibility

A crucial aspect of a laser cutter and engraver machine is its compatibility with various materials. Common materials used with laser engravers include:

- Wood

- Acrylic

- Glass

- Metal

- Leather

- Rubber

Each material interacts differently with the laser, requiring adjustments in power settings and speed to achieve the desired outcome. Some machines, such as the Xtool S1, are specifically designed to handle a wide range of materials efficiently.

Safety Considerations

Safety is a critical concern in operating a laser cutter and engraver. Proper measures must be taken to avoid hazards associated with such powerful machinery. Key safety tips include:

- Wearing appropriate eye protection

- Adequate ventilation to prevent fume accumulation

- Regular maintenance checks

- Adherence to manufacturer safety guidelines

The enclosed design of machines like the Xtool S1 offers additional layers of protection, safeguarding operators and environments.

Industry Best Practices

For achieving best results using a laser cutter and engraver, industry experts recommend several best practices, such as:

- Conducting test runs on scrap pieces

- Maintaining clean lenses and mirrors

- Utilizing proper vector graphics for design work

- Keeping a log of material types and settings used

Such practices ensure consistent performance and extend the lifespan of the machine.

Cost-Benefit Analysis

Investing in a laser cutter and engraver can be initially expensive, with high-quality machines costing thousands of dollars. However, the long-term benefits often outweigh these initial costs. The capability to produce intricate designs quickly and efficiently translates into higher productivity and potential profit.

Additionally, by bringing engraving functions in-house, businesses can save significant costs on outsourcing, thereby improving their bottom line.

Maintenance Tips

Maintaining a laser cutter and engraver is paramount to ensuring its continuous and efficient function. Regular maintenance tasks include:

- Checking and cleaning optics regularly

- Lubricating moving parts

- Ensuring alignment of laser beams

- Updating software periodically

Adhering to these maintenance routines not only extends the life of the machine but also ensures optimal performance.

Project Ideas and Tutorials

Laser engraving opens a world of creative possibilities. Here are some project ideas to consider:

- Custom wooden signs for home decor

- Personalized leather wallets

- Engraved glassware for events

- Metal business cards for a professional touch

For those new to laser engraving, numerous tutorials and online communities exist to help you start and expand your crafting skills. Engaging in these projects can be both fulfilling and educational.

Conclusion

The laser cutter and engraver is a vital tool in modern manufacturing and creative industries, offering unparalleled accuracy and versatility. By understanding the technology, applications, and maintenance required, users can harness the full potential of their machines, whether for personal or professional use. As this technology continues to evolve, the possibilities are endless for those willing to explore them.