The RISD Laser Cutter: A Comprehensive Guide

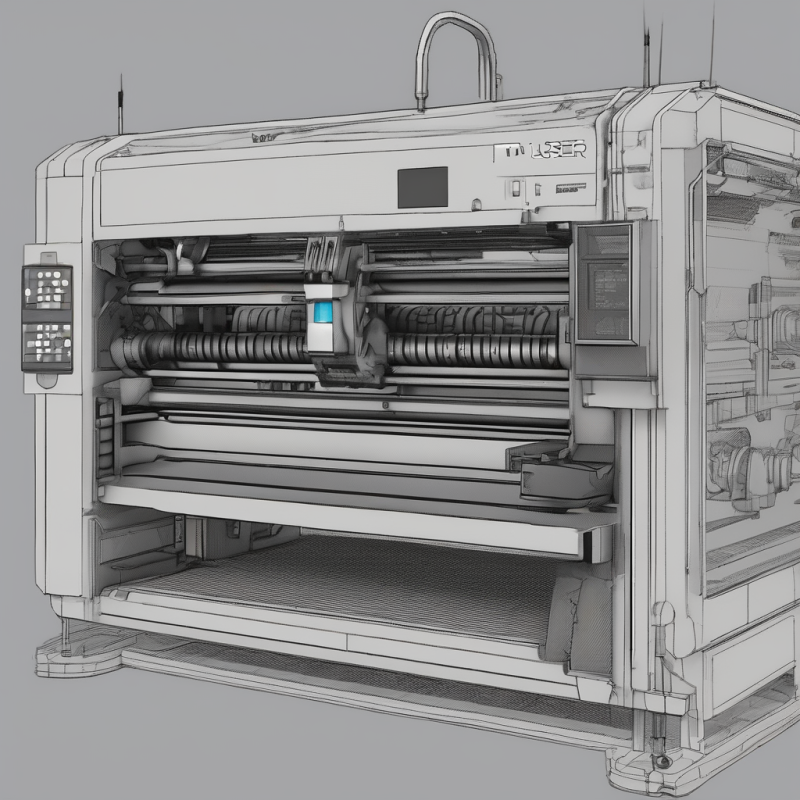

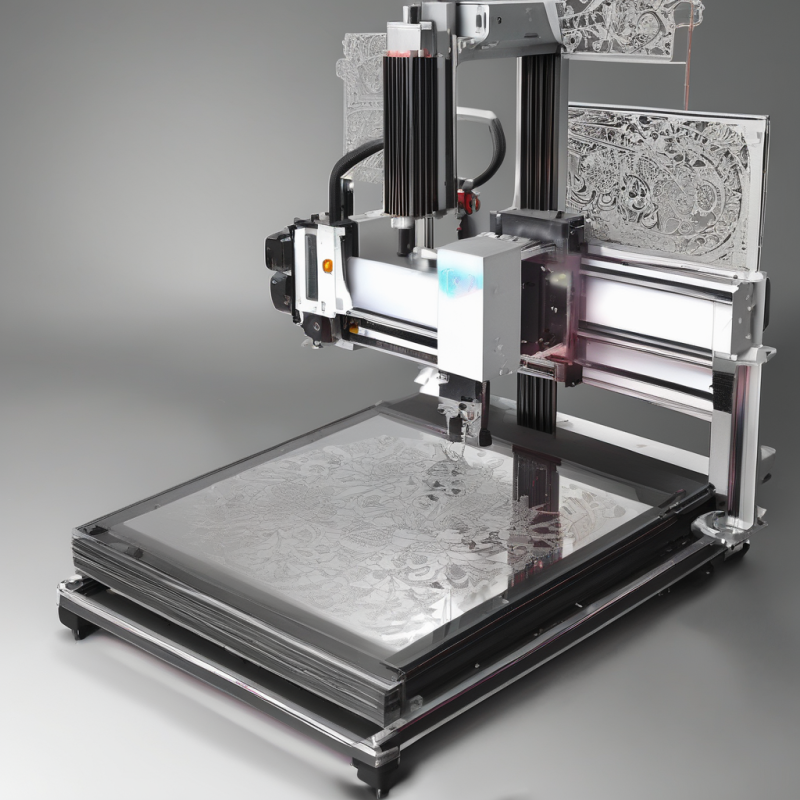

When it comes to precision cutting and engraving, the has become a go-to tool for professionals and hobbyists alike. This powerful machine offers exceptional versatility, allowing users to work with various materials such as wood, metal, plastic, and more. Whether you’re creating intricate designs or producing high-quality engravings, the RISD laser cutter is designed to deliver precise results every time. In this article, we’ll dive into its features, applications, benefits, and answer some frequently asked questions to help you decide if it’s the right tool for your projects.

Key Features of the RISD Laser Cutter

The is packed with features that make it a standout in its category. One of its most notable attributes is its high precision cutting capability, ensuring clean and accurate results even on delicate materials. The machine also boasts an intuitive interface, making it user-friendly for both beginners and experienced users. Additionally, the fiber laser technology used in this cutter provides efficient energy conversion, resulting in lower operating costs compared to traditional CO2 lasers.

Another highlight is its versatility. The RISD laser cutter can handle a wide range of materials, from thin paper to thick wood and metal sheets. This makes it an ideal choice for artists, crafters, and manufacturers looking for a multi-purpose tool. Furthermore, the machine’s adjustable focal length allows for consistent cutting and engraving across different material thicknesses, ensuring professional-grade results every time.

Applications of the RISD Laser Cutter

The applications of the are as diverse as they are impressive. One common use is woodworking, where it can create intricate designs, patterns, and engravings on wooden surfaces. This makes it a favorite among furniture makers, wood artists, and DIY enthusiasts. Another popular application is metal cutting, which is perfect for crafting custom signs, jewelry, and decorative metalwork.

Beyond materials like wood and metal, the RISD laser cutter can also work with plastics, acrylics, and even fabrics. This versatility opens up possibilities in industries such as signage production, jewelry making, prototype development, and artistic engraving. Whether you’re creating a small batch of custom items or working on large-scale projects, the RISD laser cutter is capable of handling it all with ease.

Benefits of Using the RISD Laser Cutter

There are numerous benefits to choosing the over traditional cutting methods. One of the most significant advantages is its precision. Unlike manual tools or older laser systems, the RISD cutter delivers extremely accurate cuts and engravings, minimizing waste and maximizing efficiency. This precision also allows for intricate designs that would be difficult to achieve with other tools.

Another key benefit is its ease of use. The machine’s intuitive interface and user-friendly controls make it accessible even to those who are new to laser cutting. Additionally, the fiber laser technology ensures lower maintenance costs and longer service life compared to CO2 lasers. This makes the RISD cutter a cost-effective investment for both small-scale and large-scale operations.

Maintenance and Safety Considerations

While the is designed to be durable, proper maintenance is essential for optimal performance and longevity. Regular cleaning of the optics and lenses is necessary to prevent dust or debris from affecting the machine’s accuracy. Additionally, it’s important to follow the manufacturer’s guidelines for lubrication and calibration to ensure smooth operation.

Safety should also be a top priority when using any laser cutting equipment. Always wear appropriate protective gear, such as goggles and gloves, and operate the machine in a well-ventilated area to avoid inhaling fumes from materials like wood or plastic. By adhering to safety protocols, you can maximize the machine’s lifespan while ensuring a safe working environment.

Frequently Asked Questions

If you’re considering purchasing the RISD laser cutter, you might have some questions about its capabilities and performance. Here are answers to some of the most common inquiries:

1. **What materials can the RISD laser cutter work with?**

The RISD laser cutter is capable of cutting and engraving a wide variety of materials, including wood, metal, plastic, acrylics, and fabrics. Its versatility makes it suitable for numerous applications across different industries.

2. **Is the machine user-friendly?**

Yes, the features an intuitive interface that makes it easy to operate, even for those who are new to laser cutting.

3. **How precise is the RISD laser cutter?**

The machine offers exceptional precision, with the ability to create intricate designs and clean cuts on various materials. This makes it ideal for both small-scale and large-scale projects.

4. **What are the maintenance requirements?**

Regular cleaning of optics, lenses, and other components is essential to ensure optimal performance. Follow the manufacturer’s guidelines for lubrication and calibration to maintain the machine’s efficiency.

Conclusion

The is a versatile and powerful tool that has become a favorite among professionals and hobbyists alike. Its precision, ease of use, and versatility make it an excellent choice for a wide range of applications, from woodworking to metal cutting and beyond. Whether you’re a seasoned or just starting out, this machine offers the performance and reliability needed to bring your creative visions to life.

If you’re looking for a high-quality laser cutter that can handle various materials with ease, the RISD laser cutter is definitely worth considering. Its combination of advanced technology, user-friendly design, and exceptional precision makes it a standout option in the market. Don’t hesitate to explore its capabilities and see how it can transform your projects into works of art.