The Ultimate Guide to 3D Printer Laser Engravers: Unveiling Their Potential

Are you curious about the fascinating world of 3D printer laser engravers? If so, you’ve come to the right place. In this comprehensive guide, we’ll explore everything you need to know about these innovative machines, their capabilities, and how they can transform your projects into masterpieces. Whether you’re a hobbyist, an artist, or a professional, this article will provide you with valuable insights into the world of laser engraving.

What is a 3D Printer Laser Engraver?

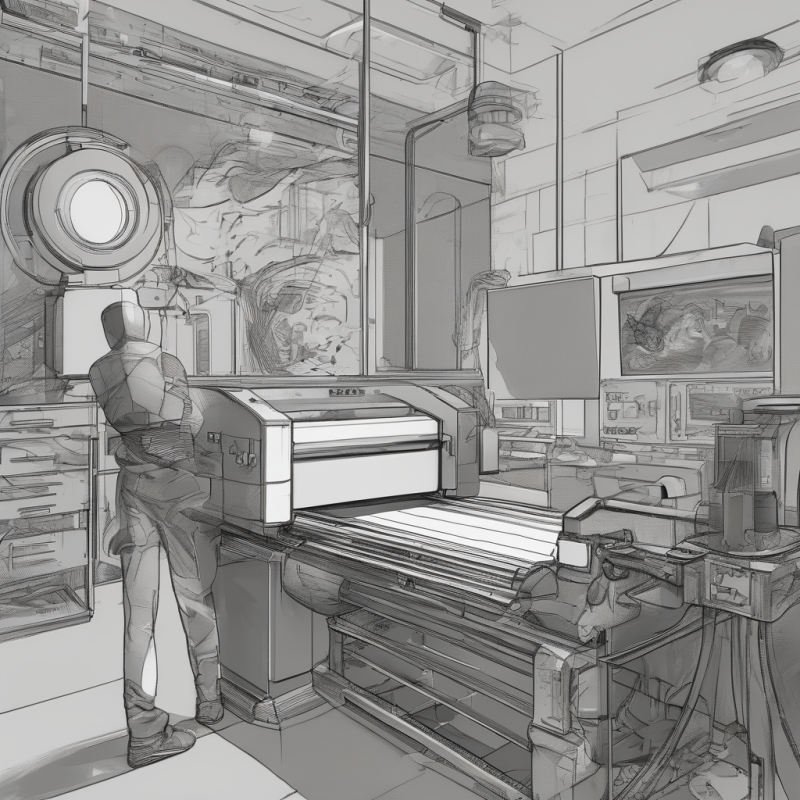

A 3D printer laser engraver is a cutting-edge tool that combines the precision of laser technology with the creativity of 3D printing. Unlike traditional engraving methods, which often involve manual carving or mechanical tools, laser engravers use focused light beams to etch intricate designs onto various materials. This process is not only faster but also more accurate, making it ideal for a wide range of applications.

The device works by directing a high-powered laser beam at the material’s surface. The laser heats and vaporizes the material, creating permanent marks without physically removing any material. This makes it perfect for delicate surfaces that might be damaged by traditional engraving methods. Whether you’re working with wood, metal, glass, or plastic, a 3D printer laser engraver can handle it all.

The Benefits of Using a 3D Printer Laser Engraver

Before diving into the technicalities, let’s discuss why you should consider investing in a 3D printer laser engraver. Here are some of its standout benefits:

- Precision and Accuracy: The laser beam is incredibly precise, allowing for intricate designs that would be nearly impossible to achieve manually.

- Versatility: It can work with a variety of materials, making it suitable for different projects and industries.

- Speed: Laser engraving is much faster than traditional methods, saving you time and effort.

- Durability: The markings created by the laser are permanent and resistant to wear and tear.

If you’re wondering, “What makes a 3D printer laser engraver stand out?”, it’s its ability to blend precision with versatility. Whether you’re creating custom jewelry, personalized gifts, or industrial components, this tool can handle it all with ease.

How Does a 3D Printer Laser Engraver Work?

To fully understand the capabilities of a 3D printer laser engraver, it’s essential to grasp how it works. The process involves several key steps:

- Design Creation: You start by creating or importing your design into specialized software. This software translates the design into instructions for the laser.

- Laser Setup: The machine is equipped with a high-powered laser that can be adjusted for intensity and focus depending on the material being engraved.

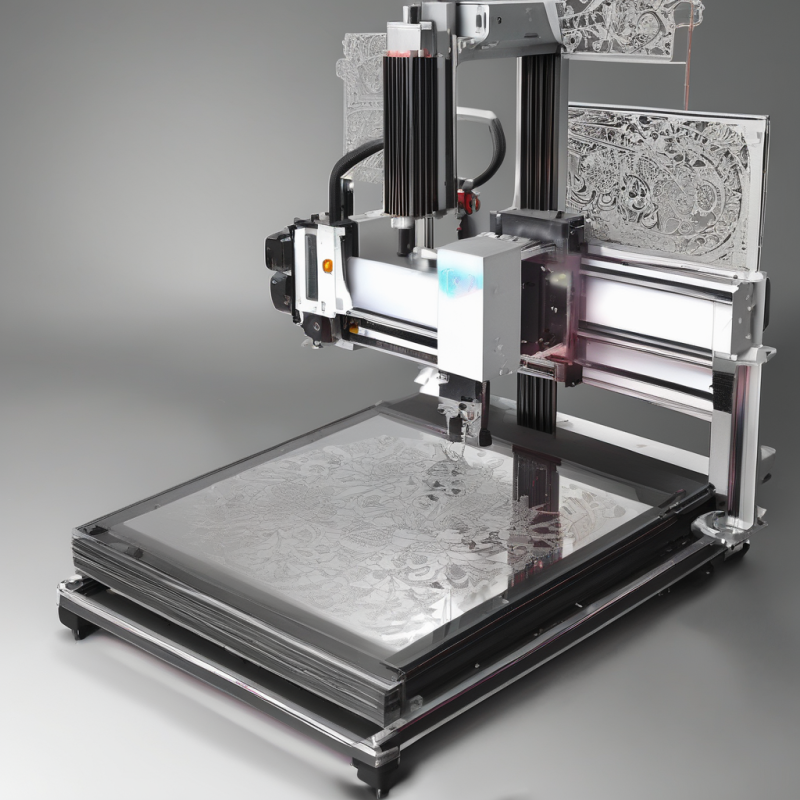

- Engraving Process: The laser beam scans across the surface of the material, precisely following the design. The heat from the laser vaporizes the material, creating the desired pattern or text.

- Post-Processing: After engraving, you may need to clean and finish the piece to enhance its appearance or durability.

If you’re asking yourself, “How does a laser engraver differ from a traditional printer?”, it’s all about the method of marking. While traditional printers use ink or toner, laser engravers use focused light beams to create permanent marks on various materials.

Applications of 3D Printer Laser Engravers

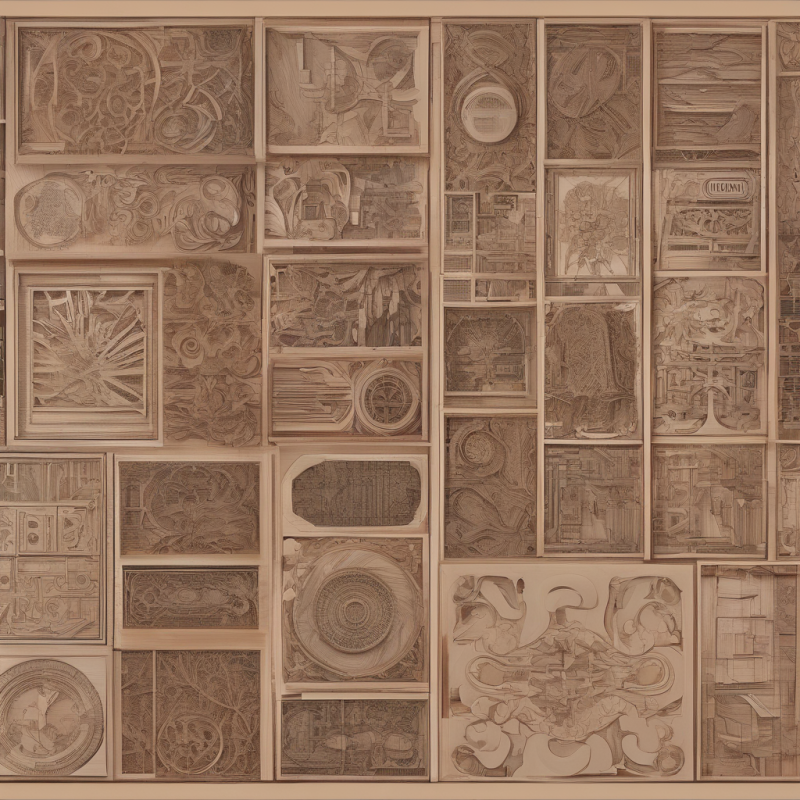

The versatility of a 3D printer laser engraver makes it applicable in numerous fields. Here are some of the most common uses:

- Crafts and Art: Create personalized jewelry, decorative items, and artistic masterpieces with intricate designs.

- Industrial Use: Mark serial numbers, logos, or other identifiers on machinery, tools, and components.

- Customization: Engrave names, dates, or custom messages on items like wedding rings, keychains, and plaques.

- Fabrication: Use the laser to cut or etch materials for prototyping, model making, or small-scale production.

If you’re curious about “What industries benefit most from laser engraving?”, the answer is almost any industry that requires precise and permanent markings. From fashion and automotive to electronics and aerospace, the applications are endless.

Choosing the Right 3D Printer Laser Engraver

With so many options available, selecting the right 3D printer laser engraver can be overwhelming. Here are some factors to consider:

- Budget: Determine how much you’re willing to spend, as prices vary widely depending on features and capabilities.

- Material Compatibility: Ensure the machine can work with the materials you plan to use. Some lasers are better suited for certain materials than others.

- Software Support: Look for machines that come with user-friendly software or are compatible with popular design programs like Adobe Illustrator or AutoCAD.

- Maintenance and Support: Check the availability of replacement parts, technical support, and maintenance services.

If you’re wondering, “What’s the best laser engraver for beginners?”, it’s one that offers simplicity in operation while still providing enough power for basic projects. Many models come with preloaded designs or templates to help you get started.

Tips for Getting Started with Laser Engraving

If you’re new to laser engraving, here are some tips to help you get started:

- Practice First: Start with simple designs and inexpensive materials to familiarize yourself with the machine’s capabilities.

- Experiment with Materials: Test different materials to see how they react to the laser. This will give you a better understanding of what works best for your projects.

- Use Protective Gear: Always wear safety goggles and ensure proper ventilation when operating the machine, as it produces fumes during the engraving process.

- Follow Instructions: Read the user manual carefully and follow all safety guidelines to avoid accidents or damage to the equipment.

If you’re asking, “How long does it take to learn laser engraving?”, the answer depends on your dedication and practice. With consistent effort, you can master the basics in a few weeks.

Frequently Asked Questions About 3D Printer Laser Engravers

Q: Can I use a laser engraver for both cutting and engraving?

A: Yes, many 3D printer laser engravers are capable of both cutting and engraving, depending on the settings and power levels used.

Q: Is it safe to use a laser engraver at home?

A: As long as you follow safety precautions, such as wearing protective gear and ensuring good ventilation, using a laser engraver at home is perfectly safe.

Q: What’s the difference between a laser cutter and a laser engraver?

A: While both use lasers, cutters are designed for cutting through materials entirely, whereas engravers are used to create surface markings without cutting all the way through.

Conclusion

In conclusion, a 3D printer laser engraver is an incredibly versatile and powerful tool that can elevate your projects to new heights. Whether you’re a hobbyist looking for a creative outlet or a professional seeking precise and permanent markings, this machine has something to offer everyone.

If you’re ready to take the plunge into the world of laser engraving, do some research, read reviews, and choose a model that best fits your needs. With practice and patience, you’ll be creating stunning designs in no time!

Introduction

A 3D printer laser engraver is an innovative tool that combines printing and engraving capabilities, enabling users to create intricate designs on various materials. This guide provides insights into its applications, benefits, and considerations for choosing the right machine.

—

What Is a 3D Printer Laser Engraver?

A 3D printer laser engraver uses lasers to etch or cut detailed patterns onto surfaces, offering precision and versatility across multiple industries.

—

Applications of 3D Printer Laser Engravers

1. **Crafts and Art**: Ideal for creating personalized jewelry, decorative items, and artistic pieces.

2. **Industrial Use**: Useful for marking serial numbers, logos, or identifiers on machinery and tools.

3. **Customization**: Engrave names, dates, or messages on products like wedding rings or keychains.

4. **Fabrication**: Cut or etch materials for prototyping and small-scale production.

—

Benefits of Using a 3D Printer Laser Engraver

– **Precision and Detail**: Creates intricate designs with high accuracy.

– **Versatility**: Works on various materials, including wood, metal, and plastic.

– **Efficiency**: Fast and automated process suitable for both small-scale projects and large production runs.

—

How to Choose the Right 3D Printer Laser Engraver

1. **Budget**: Determine your budget as prices vary widely based on features.

2. **Material Compatibility**: Ensure the machine works with your preferred materials.

3. **Software Support**: Look for user-friendly software or compatibility with design programs like Adobe Illustrator.

4. **Maintenance and Support**: Check availability of parts, technical support, and maintenance services.

—

Tips for Getting Started

1. **Practice First**: Start with simple designs on inexpensive materials.

2. **Experiment with Materials**: Test different materials to understand their reactions to the laser.

3. **Safety Gear**: Always wear protective gear and ensure proper ventilation.

4. **Follow Instructions**: Read the manual and adhere to safety guidelines.

—

FAQs

– **Q: Can a laser engraver both cut and engrave?**

Yes, many models can perform both tasks depending on settings.

– **Q: Is it safe for home use?**

Absolutely, provided you follow safety precautions.

– **Q: What’s the difference between a laser cutter and engraver?**

Cutters are for cutting through materials entirely, while engravers create surface markings.

—