The Ultimate Guide to At-Home Laser Cutter Machines

Have you ever wondered how to bring your creative ideas to life without leaving the comfort of your home? If so, an might be the perfect solution for you. These machines are revolutionizing the way people create, design, and craft intricate projects right from their homes. Whether you’re a hobbyist, a professional artist, or a small business owner, an at-home laser cutter can open up endless possibilities. But with so many options available, where do you start? This guide will walk you through everything you need to know about at-home laser cutter machines, including their benefits, types, and how to choose the right one for your needs.By the end, you’ll feel confident about diving into this exciting world and turning your ideas into reality.

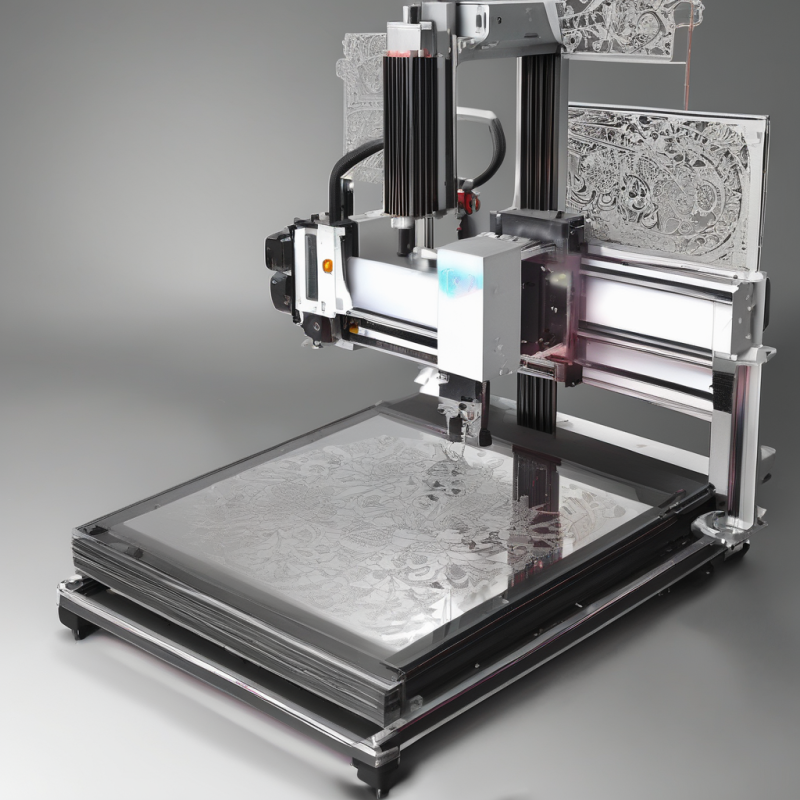

Imagine this: you’re sketching out a design for a custom wooden sign, a personalized leather wallet, or even a prototype for a new product. With an at-home laser cutter, you don’t need to send those ideas off to a workshop or wait weeks for someone else to make them. Instead, you can bring them to life yourself, tweaking and perfecting as you go. It’s like having a mini factory right at your fingertips! Let’s explore why these machines are such a game-changer and how you can find the perfect one for your creative journey.

Why Choose an At-Home Laser Cutter Machine?

The idea of having a high-tech tool like a laser cutter in your home might seem intimidating at first. However, modern at home laser cutter machine models are designed to be user-friendly and accessible for everyone. Here are some compelling reasons why you should consider investing in one:

- Creative Freedom: With a laser cutter, you can design and create custom items without relying on external services. From cutting intricate patterns to engraving detailed designs, the possibilities are endless.Want to make a one-of-a-kind gift for a friend? Done. How about a set of custom coasters for your living room? Easy. The only limit is your imagination.

- Cost-Effective: Hiring professional laser cutting services can be expensive, especially for small projects or one-off orders. Owning your own machine allows you to save money while maintaining control over your projects.Over time, the savings add up—especially if you’re someone who loves making things regularly.

- Time-Saving: No more waiting for shipping or external processing times. With an at-home laser cutter, you can complete your projects quickly and efficiently, fitting your schedule perfectly.Need something done by tomorrow? No problem—just fire up your machine and get to work.

- Versatility: Laser cutters can work with a variety of materials, including wood, metal, plastic, and even fabric. This makes them ideal for a wide range of applications, from crafting to prototyping.One day you’re etching a design onto glass, the next you’re cutting shapes out of acrylic. It’s like having a multi-tool for every creative task.

If you’re still unsure, ask yourself: Do I want to take my creative projects to the next level without leaving my home? If the answer is yes, then an at-home laser cutter machine could be your new best friend.

Picture this: instead of scrolling through online stores for the perfect decor piece, you’re designing it yourself in an afternoon. Or maybe you’re testing a new product idea without spending a fortune on outsourcing. That’s the power of bringing laser cutting home—it’s not just a tool; it’s a lifestyle upgrade.

But it’s not all about creativity. These machines also bring practical benefits. For small business owners, they can cut production costs and speed up turnaround times. For parents, they’re a fun way to work on projects with kids (with proper supervision, of course). And for anyone who loves DIY, they’re a dream come true. Ready to see why so many people are jumping on this trend? Let’s dive deeper.

Types of At-Home Laser Cutter Machines

Before diving into the world of laser cutting, it’s important to understand the different types of machines available. Here are some common categories:

- Desktop Models: These compact machines are perfect for small spaces and light-duty projects. They are ideal for hobbyists and those who want to experiment with laser cutting without a significant investment.Think of them as the “starter pack” of laser cutters—small enough to fit on a desk but powerful enough to handle wood, acrylic, and even thin metal. Brands like the xTool D1 or Glowforge Spark are popular examples, offering work areas around 400 x 300 mm.

- Industrial-Grade Machines: If you’re running a small business or need high-capacity production, industrial-grade laser cutters offer powerful performance and precision. However, they usually come with a higher price tag and require more space.These machines can cut thicker materials and handle heavy workloads, making them perfect for entrepreneurs or serious crafters. Something like the Epilog Fusion Pro might be overkill for a beginner but a dream for a pro.

- Portable Units: For those who need flexibility, portable laser cutters are a great option. They can be moved easily and used in different settings, making them versatile for on-the-go projects.Weighing as little as 10-20 pounds, units like the xTool F1 are lightweight and compact, ideal for craft fairs or shared workspaces.

Your choice of machine will depend on your specific needs, budget, and the scale of your projects. What type of projects do you plan to work on? This is a crucial question to ask yourself before making a purchase.

If you’re just dipping your toes into laser cutting, a desktop model might be all you need. But if you’re dreaming of turning your hobby into a side hustle, you might want to think bigger. To help you visualize your options, here’s a handy comparison table:

Table 1: Types of At-Home Laser Cutters

| Type | Best For | Work Area (Avg.) | Power Range | Price Range |

|---|---|---|---|---|

| Desktop Models | Hobbyists, Small Projects | 400 x 300 mm | 10-40W | $500 – $2,000 |

| Industrial-Grade | Businesses, Heavy Use | 900 x 600 mm | 50-150W | $5,000 – $20,000 |

| Portable Units | Flexibility, On-the-Go | 300 x 200 mm | 5-20W | $300 – $1,500 |

This table gives you a snapshot of what each type offers. A desktop model might be perfect for cutting jewelry or small decor, while an industrial-grade machine could churn out dozens of items a day. Portable units? They’re your go-to if you’re always on the move. Think about your space, your goals, and how often you’ll use it—the right fit is out there waiting for you.

How to Choose the Right At-Home Laser Cutter Machine

Selecting the perfect laser cutter for your home can be overwhelming. Here are some tips to help you make an informed decision:

- Budget Considerations: Determine how much you’re willing to spend. Entry-level machines start at around $500, while high-end models can cost thousands of dollars. Remember that higher-priced machines often come with additional features and better build quality.For example, a $500 machine might cut thin wood and engrave glass, but a $2,000 model could handle thicker materials and offer faster speeds. Set a budget, but leave a little wiggle room for accessories like ventilation or extra lenses.

- Material Compatibility: Think about the types of materials you plan to work with. Different laser cutters are designed for specific materials, so make sure your machine can handle what you need.Diode lasers (common in cheaper models) are great for wood and acrylic but struggle with metal. CO2 lasers, found in mid-to-high-end machines, can tackle a broader range, including fabric and thin metals. Check the specs before you buy!

- Software Integration: Most modern laser cutters come with user-friendly software that allows you to design and control your projects. Check reviews to ensure the software is compatible with your skills and needs.Programs like LightBurn or xTool Creative Space are popular and intuitive, but some machines come with proprietary software that might have a learning curve. If you’re not tech-savvy, look for something plug-and-play.

- Size and Space: Measure your workspace to ensure the machine fits comfortably. Desktop models are great for small spaces, while larger machines may require dedicated areas.A desktop cutter might be 20 inches wide, but an industrial one could take up a whole corner of your room. Factor in extra space for ventilation and materials, too—you don’t want to feel cramped.

By evaluating these factors, you can narrow down your options and find an at-home laser cutter machine that perfectly suits your requirements. Are there specific features you prioritize? This is another important question to consider during your search.

Maybe you want a built-in camera for precise alignment, or perhaps speed is your top concern. To make things even clearer, here’s a table of popular models based on recent reviews (as of early 2025):

Table 2: Popular At-Home Laser Cutters (2025)

| Model | Type | Power | Work Area | Key Feature | Price |

|---|---|---|---|---|---|

| xTool D1 Pro | Desktop | 20W | 430 x 400 mm | Affordable Precision | $999 |

| Glowforge Plus | Desktop | 40W | 495 x 279 mm | Easy-to-Use Software | $4,995 |

| xTool F1 | Portable | 10W | 115 x 115 mm | Ultra-Portable Design | $1,299 |

| Epilog Zing 24 | Industrial | 50W | 610 x 305 mm | High-Volume Capacity | $12,000 |

This table highlights real-world options you might come across. The xTool D1 Pro is a budget-friendly powerhouse for beginners, while the Glowforge Plus offers premium features for a higher cost. The xTool F1 is perfect for portability, and the Epilog Zing 24 is a beast for serious users. Match these to your needs, and you’re halfway to picking a winner.

But don’t stop at the basics. Think about extras like air assist (for cleaner cuts) or rotary attachments (for engraving round objects like mugs). Talk to other users online—Reddit forums or YouTube reviews can give you unfiltered insights. The goal? Find a machine that feels like an extension of your creativity, not a hassle.

Maintenance and Safety Tips

Like any high-tech tool, an at-home laser cutter machine requires proper maintenance and safety precautions. These machines use powerful lasers to cut and engrave, so treating them with care is non-negotiable. Here are some tips to keep your machine running smoothly and your workspace safe:

- Regular Cleaning: Dust and debris can accumulate inside the machine over time. Clean it regularly to ensure optimal performance.Use a soft brush or compressed air to clear out the bed and exhaust areas after every few uses. A clean machine cuts better and lasts longer—think of it like dusting your furniture, but with a high-tech twist.

- Lens Care: The laser lens is a critical component of your machine. Handle it with care and avoid touching the surface to prevent scratches or smudges.Clean it weekly with a microfiber cloth and lens cleaner (check your manual for specifics). A dirty lens can weaken your cuts, so treat it like the delicate gem it is.

- Follow Safety Guidelines: Always wear protective eyewear when operating the machine. Keep flammable materials away from the work area, and ensure proper ventilation to avoid inhaling fumes.Laser cutters can produce smoke, especially with materials like wood or plastic, so a fume extractor or an open window is a must. Never leave the machine running unattended—fires can start in seconds.

- Software Updates: Keep your machine’s software up to date to access the latest features and improvements.Manufacturers often release patches to fix bugs or enhance performance, so check for updates monthly. It’s like updating your phone—small effort, big payoff.

Taking these steps will not only extend the life of your machine but also ensure a safe and efficient working environment. Are you ready to take the plunge into the world of laser cutting?

To give you a clearer picture, here’s a maintenance schedule based on typical use:

Table 3: Laser Cutter Maintenance Schedule

| Task | Frequency | Tools Needed | Why It Matters |

|---|---|---|---|

| Clean Machine Bed | After Every Use | Brush, Compressed Air | Prevents Debris Buildup |

| Clean Lens | Weekly | Microfiber Cloth, Cleaner | Maintains Cutting Precision |

| Check Ventilation | Monthly | Visual Inspection | Ensures Safe Fume Removal |

| Update Software | Monthly | Internet Connection | Keeps Features Current |

Stick to this schedule, and your machine will thank you with years of reliable service. Safety-wise, always read your manual—different models have quirks. For example, some need specific cool-down times after heavy use. And if you’re cutting tricky materials like PVC (which releases toxic fumes), just don’t—stick to safe options like wood or acrylic. With a little care, you’ll be lasering like a pro in no time.

Conclusion

An at home laser cutter machine is more than just a tool—it’s a gateway to creativity, efficiency, and endless possibilities. Whether you’re crafting personalized gifts, prototyping new products, or simply exploring your artistic side, having a laser cutter at home can elevate your projects to new heights. With the right research and preparation, you can find the perfect machine that fits your needs and budget. So why wait? Start your journey into the fascinating world of laser cutting today!

Think about it: in a single afternoon, you could go from an idea scribbled on a napkin to a finished product in your hands. That’s the magic of at-home laser cutting—it’s empowering, practical, and downright fun. Whether you’re a beginner etching your first design or a seasoned maker scaling up production, there’s a machine out there for you. Dive into reviews, join online communities, and start small if you’re nervous. Before you know it, you’ll wonder how you ever lived without one. Ready to make your mark? The laser’s waiting!