The Ultimate Guide to Choosing a Laser Engraving Machine for Jewelry

Introduction

Jewelry is not just an adornment; it is an expression of individuality, heritage, and sometimes, even love. With advancements in technology, creating personalized and intricate designs on jewelry has never been easier. A laser engraving machine for jewelry is revolutionizing the jewelry industry by offering unmatched precision, efficiency, and customization. Whether you are a seasoned jeweler, a jewelry manufacturer, or a passionate hobbyist, laser engraving machines open up a world of possibilities.

What is a Laser Engraving Machine for Jewelry?

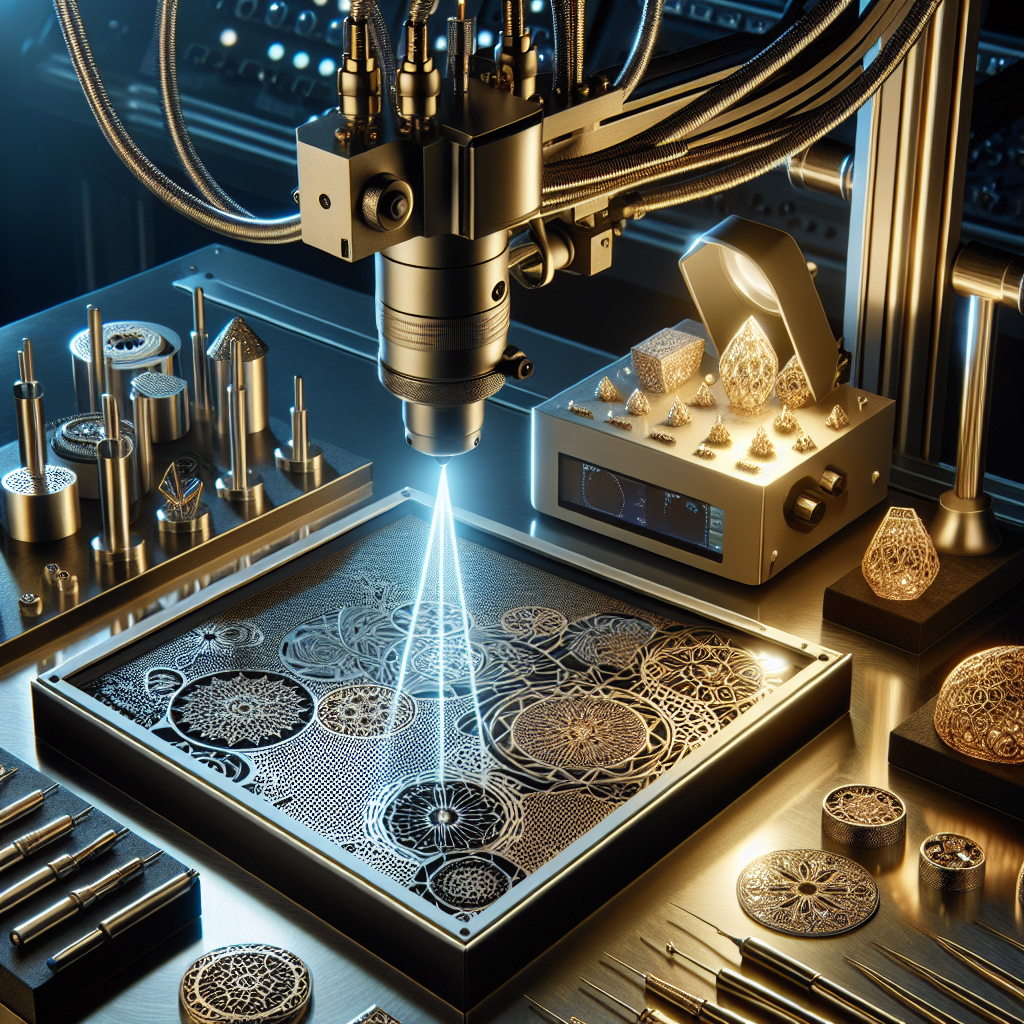

A laser engraving machine for jewelry is an advanced technology tool that uses focused laser beams to etch detailed patterns, text, or images onto a variety of surfaces. Unlike traditional engraving methods, which often involve tools physically touching the material, laser engraving is a contact-free process. This allows for higher precision and ensures that even the most delicate materials, such as gold or silver, remain unscathed during the process.

Modern laser engravers are equipped with features that make them highly adaptable, allowing users to design and execute anything from simple text engravings to complex artistic designs. This versatility has made them an essential tool for jewelers looking to add unique and intricate details to their creations.

Key Features of Laser Engraving Machines for Jewelry

When it comes to choosing the right laser engraving machine for jewelry, understanding the machine’s features is crucial. Here are some key aspects to look for:

- Precision and Accuracy: Jewelry engraving demands incredible precision, as even the smallest design flaw can be visible. Look for machines that offer high-resolution engraving capabilities.

- Compatibility with Various Materials: Jewelry involves a mix of precious metals (gold, silver, platinum) and non-metal materials (gemstones, acrylic, wood), so your machine should handle diverse materials effortlessly.

- Speed Settings: Adjustable speed options allow you to work on both intricate designs and bulk production without compromising quality.

- Advanced Software Integration: Look for machines compatible with professional design software like AutoCAD, CorelDRAW, or Adobe Illustrator. This ensures seamless design-to-engraving execution.

- Compact Size: If space is a concern, portable yet powerful laser engraving machines are perfect choices for small studios.

Applications of a Laser Engraving Machine for Jewelry

Laser engraving technology has a broad spectrum of applications in the jewelry industry. Some of the most common uses include:

- Engraving names or special dates on wedding bands and engagement rings

- Etching logos or brand names for jewelry businesses

- Creating intricate patterns and designs on pendants, bracelets, and earrings

- Engraving serial numbers or authenticity marks for certification purposes

- Customizing gifts with personal messages or images

Regardless of the project’s complexity, the versatility of a laser engraving machine for jewelry ensures that you’ll achieve a professional finish every time.

Material Compatibility: Can a Laser Engraving Machine Handle All Metals?

One of the most exciting aspects of laser engraving machines is their ability to work with a variety of materials. A high-quality laser engraving machine for jewelry can typically engrave materials such as:

- Gold: Perfect for engraving delicate and expensive jewelry pieces like wedding bands.

- Silver: A popular material used in necklaces, bracelets, and other accessories.

- Platinum: A durable and luxurious option for high-end jewelry items.

- Titanium: Often used in contemporary jewelry designs, titanium is ideal for engraving due to its hardness.

- Non-metals: Some machines also support acrylic, wood, and even some gemstones, expanding design possibilities.

It’s important to note that not all laser engraving machines are compatible with every material. Carefully review the machine’s specifications to ensure it meets your specific needs.

Safety First: Guidelines for Laser Engraving Jewelry Safely

Using a laser engraving machine for jewelry offers phenomenal results, but safety should always come first. Here are some tips to ensure a safe engraving experience:

- Wear Protective Gear: Always use safety glasses to protect your eyes from laser light.

- Provide Adequate Ventilation: Laser engraving produces fumes and vapors, particularly if you’re engraving coated metals. Use an exhaust system for proper airflow.

- Follow Manufacturer Instructions: Understand the machine’s capabilities and limitations to avoid accidents.

- Keep Materials Secure: Ensure the material you’re engraving is firmly positioned to avoid any movement during the process.

- Monitor the Machine: Avoid leaving the machine unattended while in operation.

How Much Does a Laser Engraving Machine for Jewelry Cost?

Cost is often a significant consideration when investing in new technology. While a laser engraving machine for jewelry might seem expensive upfront, its long-term benefits often outweigh the initial investment. Factors influencing price include:

- Machine’s power and features

- Brand reputation

- Compatibility with various materials

- Warranty and post-purchase support

For jewelers aiming to scale their business, the return on investment is significant. The ability to create custom designs at a rapid pace can help attract new customers and diversify your offerings.

Maintenance Tips for Prolonging the Longevity of Your Machine

Proper maintenance ensures that your laser engraving machine for jewelry performs optimally for years. Here are some actionable tips:

- Regular Cleaning: Remove dust and debris from the laser lens and other components to maintain precision.

- Calibrate Periodically: Check the focus and alignment of the laser to ensure consistent performance.

- Replace Worn-Out Parts: Regularly inspect and replace components like belts and nozzles, as necessary.

- Software Updates: Keep the machine’s software up-to-date to access new features and improve compatibility with design programs.

Creative Project Ideas for Jewelers

If you’re new to using a laser engraving machine for jewelry, starting with simple but creative projects can help you master the craft:

- Personalized wedding band inscriptions

- Custom pendant designs featuring initials or dates

- Engraved charms and keepsakes

- Complex geometric or floral patterns on metal bracelets

- Engraving gemstones with tiny symbols for added flair

The sky’s the limit when it comes to creating unique and meaningful jewelry designs!

Final Thoughts

A laser engraving machine for jewelry is not just a tool; it’s a gateway to boundless creativity and precision. By investing in this technology, you’ll unlock the potential to offer personalized and high-quality jewelry that stands out in today’s competitive market. Pairing advanced features with regular maintenance will ensure that your laser engraving machine serves your business or hobby for years to come.

Are you ready to elevate your jewelry creations to new heights? If so, why not explore the latest options and take your first step into the future of jewelry engraving?