The Ultimate Guide to CNC Laser Cutter Machines: A Comprehensive Overview

CNC laser cutter machines have revolutionized modern manufacturing by offering unparalleled precision and efficiency in cutting materials. These machines are essential tools for industries ranging from metalworking to electronics, enabling the creation of intricate designs with ease. If you’re curious about how these devices work or considering purchasing one, this guide will provide you with all the necessary information.

What is a CNC Laser Cutter Machine?

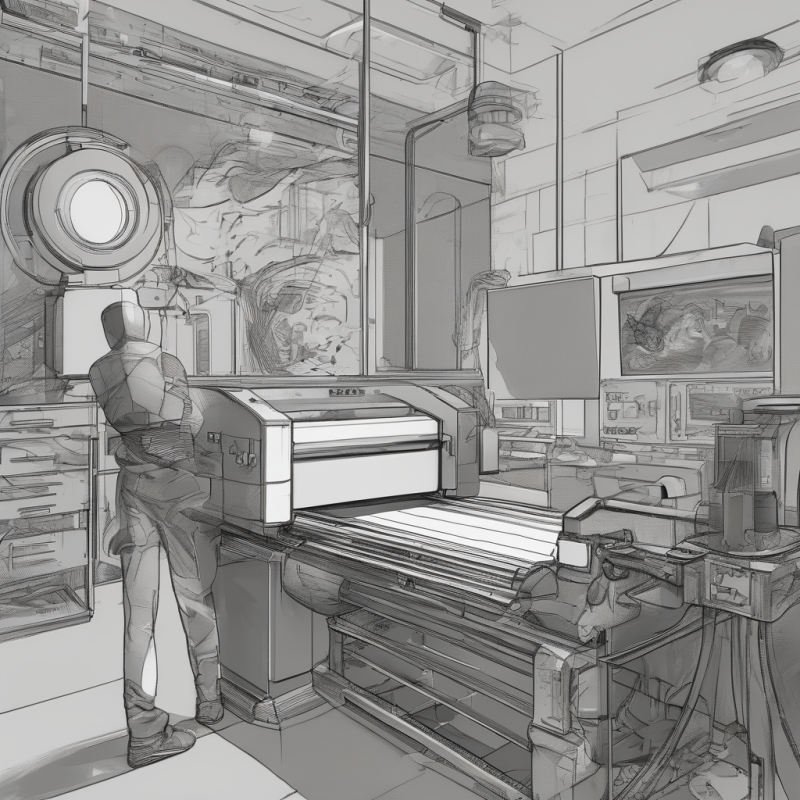

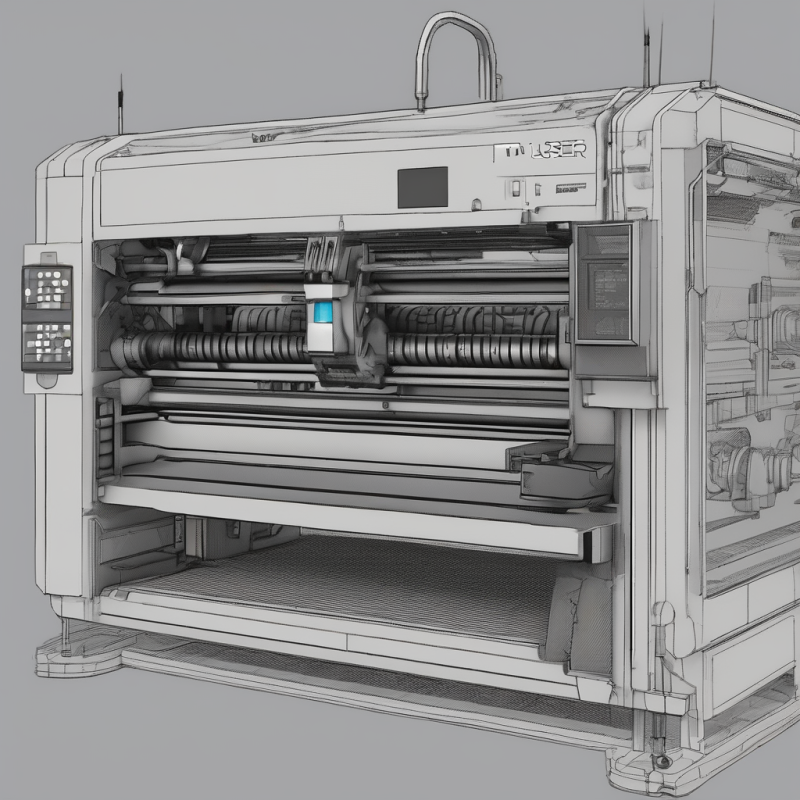

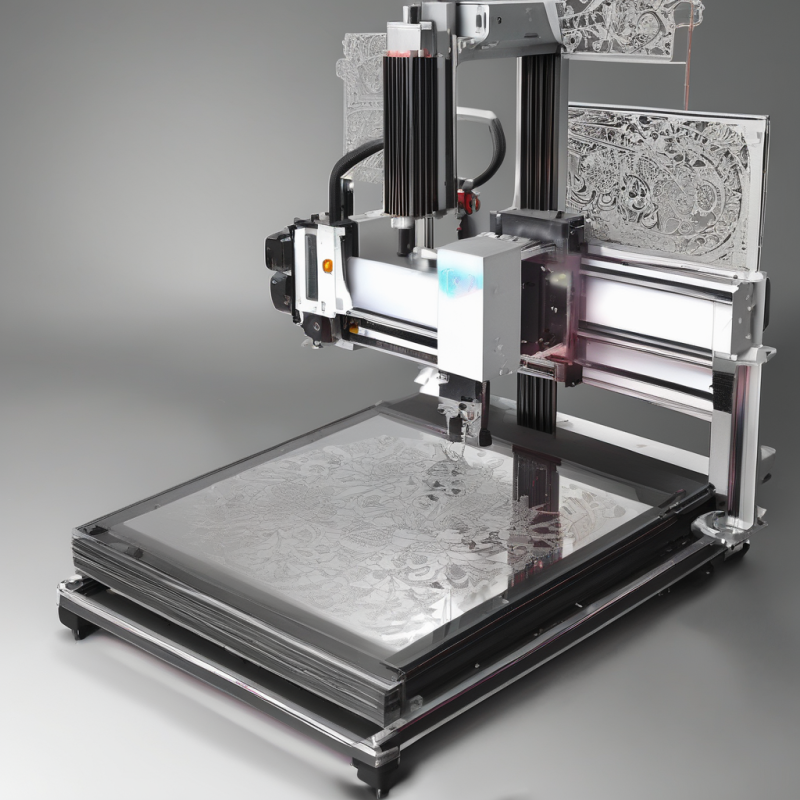

A CNC laser cutter machine stands for Computer Numerical Control Laser Cutter. It uses a focused laser beam to cut through various materials, including metal, plastic, wood, and glass. The machine is controlled by a computer that follows programmed instructions to achieve precise cuts. This technology combines the power of lasers with advanced software to create detailed patterns and shapes.

The process begins with designing the desired pattern on a computer-aided design (CAD) software. The CNC laser cutter then interprets these designs and executes the cuts with remarkable accuracy. This makes CNC laser cutting ideal for applications requiring high precision, such as medical devices or aerospace components.

Benefits of Using a CNC Laser Cutter Machine

There are numerous advantages to using a CNC laser cutter machine, making them a popular choice in industrial and artistic settings:

- Precision and Accuracy: The machines can achieve tolerances as low as ±0.001 inches, ensuring consistent quality across all cuts.

- Versatility: They can handle a wide range of materials and thicknesses, making them suitable for various industries.

- Speed: CNC laser cutters operate at high speeds, reducing production time and increasing efficiency.

- Reduced Waste: The precise cutting process minimizes material waste, contributing to cost savings and environmental sustainability.

- Complex Design Capabilities: Intricate designs that would be challenging or impossible with traditional methods can be easily achieved using CNC laser cutting.

These benefits make CNC laser cutter machines indispensable for businesses looking to enhance their production capabilities.

Industrial Applications of CNC Laser Cutter Machines

CNC laser cutter machines are employed across multiple industries due to their versatility and precision. Here are some key applications:

- Metalworking: Cutting sheet metal, stainless steel, and other metals for components in machinery and construction.

- Automotive Industry: Creating parts like brackets, panels, and decorative elements with high precision.

- Electronics: Cutting circuit boards and other delicate components requiring exact dimensions.

- Medical Devices: Manufacturing surgical instruments and prosthetics that demand extreme accuracy.

- Art and Crafts: Engraving and cutting intricate designs on materials like wood, glass, and acrylic for artistic purposes.

The ability to handle diverse materials and produce complex shapes makes CNC laser cutters a cornerstone of modern manufacturing.

Factors to Consider When Purchasing a CNC Laser Cutter Machine

If you’re considering investing in a CNC laser cutter machine, several factors should guide your decision:

- Budget: Determine how much you can afford, as prices vary based on power, size, and additional features.

- Laser Power: Higher wattage lasers are suitable for thicker materials but may be unnecessary for thinner cuts.

- Material Compatibility: Ensure the machine can handle the types of materials you’ll be working with.

- Software and Controls: User-friendly software and intuitive controls enhance productivity and ease of use.

- Maintenance Requirements: Regular maintenance is crucial for optimal performance; consider the availability of spare parts and support.

By evaluating these factors, you can choose a CNC laser cutter that best fits your needs and budget.

Maintenance and Safety Tips for CNC Laser Cutter Machines

To ensure longevity and reliable operation, proper maintenance is essential:

- Regular Cleaning: Dust and debris can affect performance; clean the machine regularly.

- Lens Care: Keep the laser lens free from scratches and contamination to maintain beam quality.

- Firmware Updates: Stay updated with software patches to enhance functionality and security.

- Safety Protocols: Always follow safety guidelines, such as wearing protective eyewear and ensuring adequate ventilation.

Prioritizing maintenance not only extends the life of your CNC laser cutter but also ensures consistent performance over time.

Frequently Asked Questions About CNC Laser Cutter Machines

Here are answers to some common questions about CNC laser cutter machines:

- Q: How much does a CNC laser cutter machine cost?

- A: Prices vary widely, ranging from $10,000 for smaller units to over $100,000 for high-power industrial models.

- Q: Can I cut all types of materials with a CNC laser cutter?

- A: While they can handle many materials, some substances like certain plastics may emit harmful fumes when cut. Always consult the machine’s specifications.

- Q: How easy is it to learn to use a CNC laser cutter?

- A: With basic computer skills and training, most users can operate a CNC laser cutter efficiently. Training programs are often available from manufacturers.

By addressing these questions, you can make informed decisions about purchasing and using a CNC laser cutter.

Conclusion

CNC laser cutter machines are powerful tools that have transformed manufacturing by offering precision, versatility, and efficiency. Whether for industrial production or artistic projects, they provide solutions to various cutting challenges. By understanding their capabilities, applications, and maintenance requirements, you can harness the full potential of a CNC laser cutter machine.

If you’re ready to explore the benefits of CNC laser cutting, consider visiting for high-quality machines and expert advice. Their expertise can help you select the perfect CNC laser cutter to meet your needs.