The Ultimate Guide to Engraving Machine Laser: Your All-in-One Solution for Precision Etching

Engraving has been a cherished art form for centuries, allowing creators to leave lasting impressions on various materials. With the advent of modern technology, traditional engraving tools have evolved into sophisticated devices like the engraving machine laser. This article delves into the world of laser engraving, exploring its capabilities, benefits, and applications. Whether you’re a hobbyist, an artist, or a professional, this guide will provide you with everything you need to know about laser engraving machines.

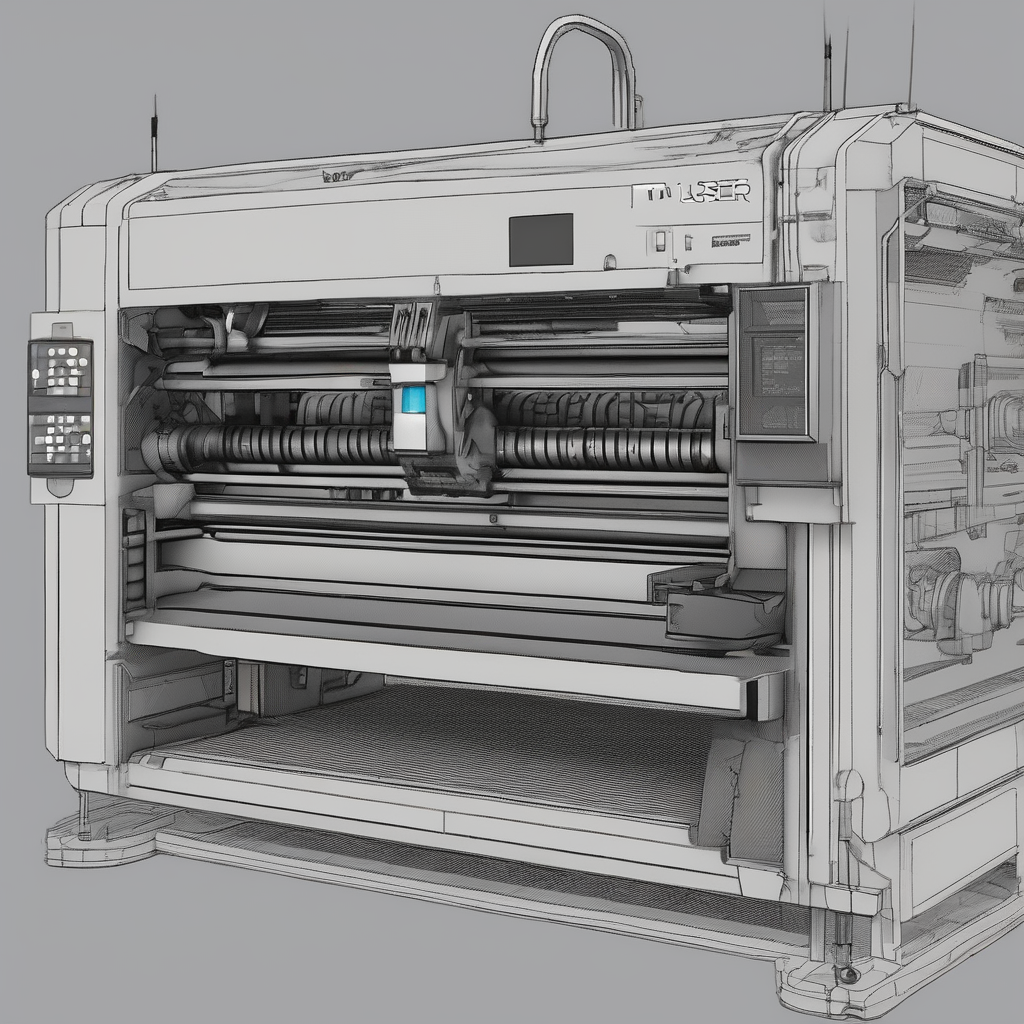

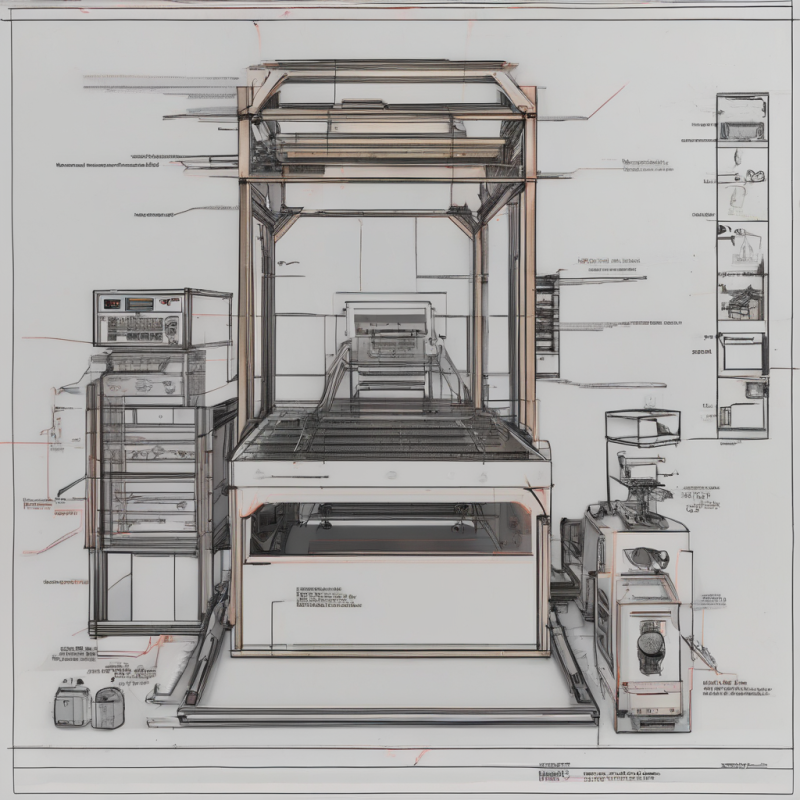

What is a Laser Engraving Machine?

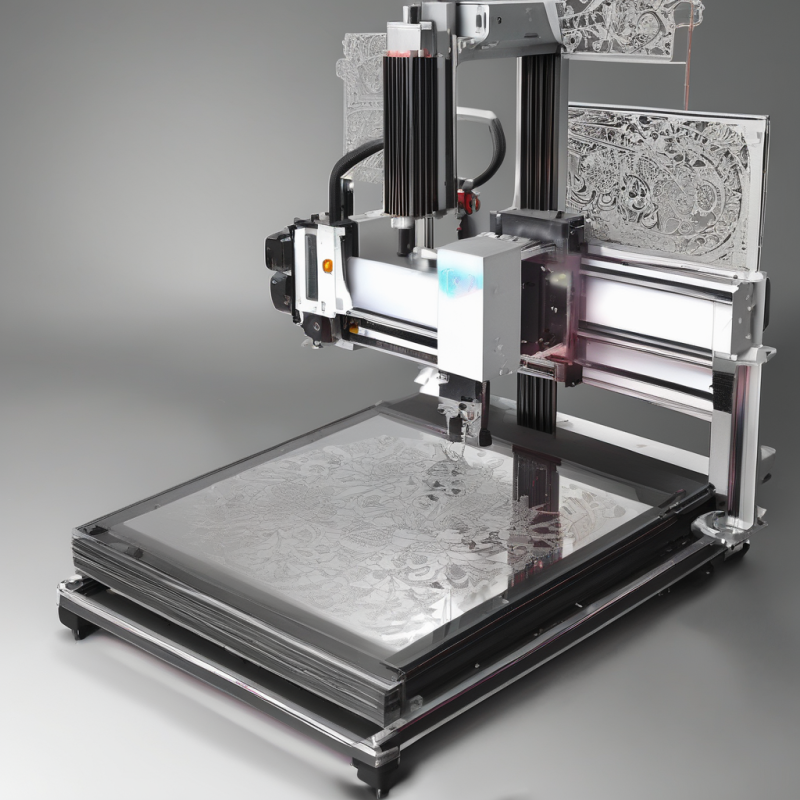

A laser engraving machine uses focused light beams to etch designs, patterns, or text onto various materials. Unlike traditional engraving tools, which rely on mechanical cutting, laser engravers offer unparalleled precision and versatility. The engraving machine laser operates by directing a high-powered laser at the material’s surface, vaporizing or removing layers to create intricate details. This method is not only faster but also more accurate, making it ideal for both small-scale projects and large-scale production.

How Does a Laser Engraving Machine Work?

To understand how a laser engraving machine works, let’s break down the process:

- The machine generates a laser beam, which is amplified and focused through lenses to create an intense light source.

- The laser beam is directed at the material’s surface, where it either melts, burns, or vaporizes the material to create the desired design.

- Modern machines often come with software that allows users to input designs, which are then translated into precise laser movements.

- The machine’s X-Y axis system ensures accurate positioning, enabling intricate patterns and text to be etched seamlessly.

This process is entirely digital, allowing for easy adjustments and corrections before the final engraving begins. The result is a clean, polished finish that traditional methods often struggle to achieve.

Types of Laser Engraving Machines

Laser engraving machines come in various forms, each tailored to specific needs:

- Handheld Laser Engravers: Compact and portable, these devices are perfect for on-the-go projects or small-scale work. They offer flexibility but may lack the precision of larger units.

- Benchtop Laser Engravers: Designed for home use, these machines are ideal for hobbyists and small businesses. They strike a balance between portability and precision.

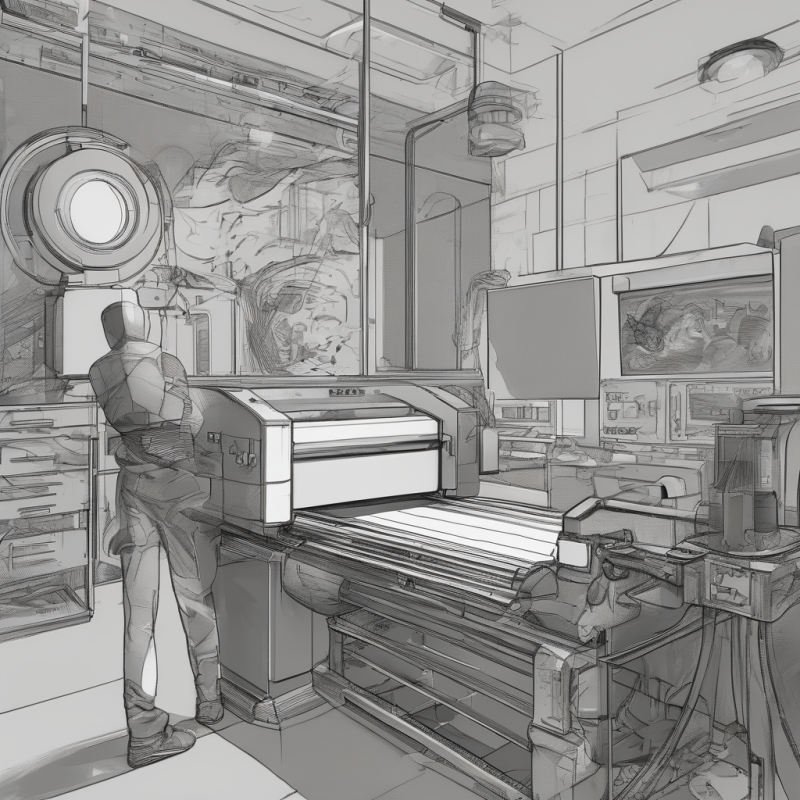

- Industrial Laser Engravers: These large-scale machines are used in manufacturing and production environments. They offer high-speed engraving with exceptional accuracy.

The handheld laser engraver mentioned earlier is a prime example of how technology has made laser engraving accessible to everyone, regardless of their skill level or budget.

Benefits of Using a Laser Engraving Machine

Switching from traditional engraving methods to a laser engraving machine comes with numerous advantages:

- Precision and Detail: Laser beams are incredibly precise, allowing for intricate designs that would be challenging to achieve manually.

- Versatility: Unlike traditional tools, which may require multiple blades or bits, a laser engraver can handle various materials with ease. This includes wood, metal, plastic, glass, and even leather.

- Speed: Laser engraving is significantly faster than manual methods, reducing production time and increasing efficiency.

- No Physical Contact: Since the laser beam doesn’t make physical contact with the material, there’s no risk of damage or wear to the tool itself.

- Eco-Friendly: Many laser engraving machines use minimal energy and produce less waste compared to traditional methods. Some models even allow for recycling materials during the engraving process.

These benefits make laser engravers a must-have tool for anyone looking to elevate their craft or streamline their production.

Applications of Laser Engraving Machines

The applications of laser engraving machines are virtually limitless. Some popular uses include:

- Jewelry Making: Creating custom designs, engravings, and patterns on metals like gold, silver, and platinum.

- Woodworking: Etching detailed wood grain patterns, logos, or artistic designs on furniture, decorative items, and musical instruments.

- Customization: Adding personalized touches to products such as nameplates, trophies, and promotional items.

- Electronic Components: Engraving circuit boards, PCBs, and other components with precise markings.

- Medical Devices: Laser engraving is used to create detailed markings on surgical instruments and implants for identification purposes.

Whether you’re working in a small workshop or a large manufacturing facility, a laser engraving machine can be tailored to meet your specific needs. The handheld laser engraver is particularly popular for its ease of use and versatility.

Choosing the Right Laser Engraving Machine

With so many options available, selecting the right laser engraving machine can be overwhelming. Here are some factors to consider:

- Budget: Determine how much you’re willing to spend, as prices vary widely depending on the machine’s size, power, and features.

- Type of Work: Consider the scale and complexity of your projects. Handheld machines are great for small-scale work, while benchtop or industrial units are better suited for larger jobs.

- Material Compatibility: Ensure the machine can handle the materials you’ll be working with. Different lasers have varying wavelengths that suit different materials.

- User-Friendliness: Look for machines with intuitive software and controls, especially if you’re new to laser engraving.

- Maintenance and Support: Check the availability of replacement parts and customer support in case issues arise.

By evaluating these factors, you can choose a machine that best fits your requirements. The handheld laser engraver is an excellent starting point for those looking to dip their toes into the world of laser engraving.

Tips for Using a Laser Engraving Machine

To get the most out of your laser engraving machine, follow these tips:

- Always Use Proper Safety Gear: Laser beams can be harmful to the eyes and skin. Wear protective goggles and gloves when operating the machine.

- Familiarize Yourself with the Software: Take time to learn how to use the accompanying software, as it plays a crucial role in creating your designs.

- Test on Scrap Material First: Before engraving your final piece, test your design on scrap material to ensure accuracy and adjust settings if necessary.

- Experiment with Different Materials: Don’t be afraid to try out various materials to see how they respond to the laser. This can lead to unexpected and creative results.

- Keep the Machine Clean: Regularly clean your laser engraving machine to maintain optimal performance and prevent dust buildup, which can interfere with the laser’s accuracy.

By adhering to these guidelines, you can maximize the potential of your laser engraving machine and produce stunning, high-quality work.

The Future of Laser Engraving

As technology continues to advance, so does the field of laser engraving. Innovations such as higher-powered lasers, improved software interfaces, and eco-friendly designs are making these machines more accessible and efficient than ever before.

Additionally, the rise of CNC (Computer Numerical Control) laser engravers is enabling even greater precision and automation in the production process. These advancements are opening up new possibilities for artists, craftsmen, and manufacturers alike.

Whether you’re a seasoned professional or just starting out, investing in a laser engraving machine like the handheld laser engraver can be a game-changer for your projects. With its versatility and precision, it’s no wonder that laser engraving is becoming an essential tool in workshops worldwide.

In conclusion, if you’re looking to take your craftsmanship or production to the next level, consider adding a laser engraving machine to your arsenal. It’s a powerful tool that offers endless creative possibilities and can help you achieve results that were once unimaginable. So why wait? Start exploring the world of laser engraving today and unlock your full potential!