The Ultimate Guide to Laser Cutter Engraver Machines: Precision at Your Fingertips

Laser cutter engraver machines have revolutionized industries by offering unparalleled precision, versatility, and efficiency. Whether you’re a hobbyist, artist, or business owner, these machines open up a world of possibilities for creating intricate designs, cutting materials with extreme accuracy, and engraving text or patterns that are both durable and visually appealing. In this comprehensive guide, we’ll explore everything you need to know about laser cutter engraver machines, including their benefits, applications, and how to choose the right one for your needs.

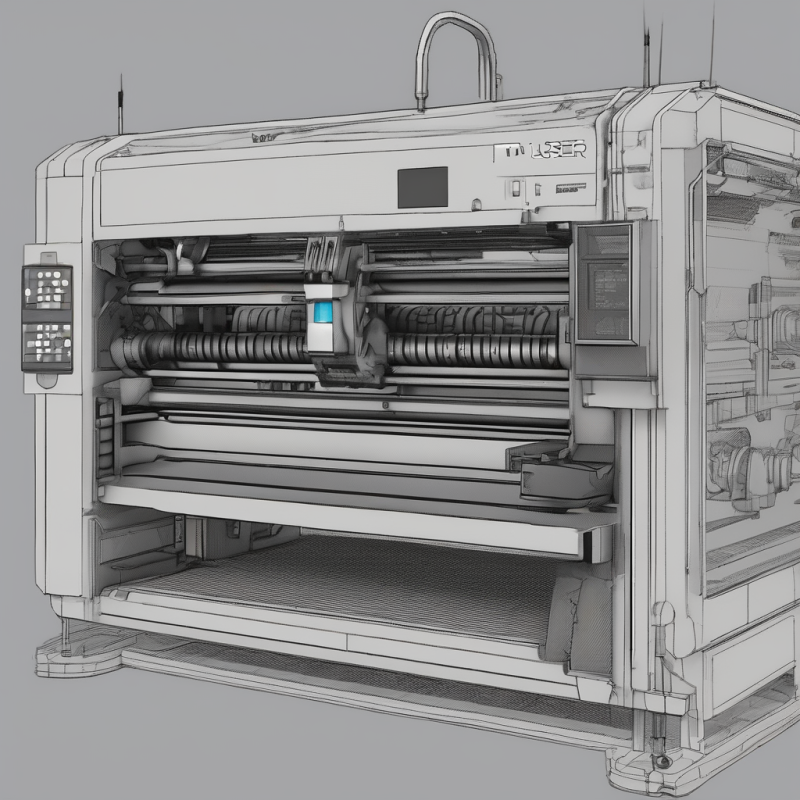

The Basics of Laser Cutter Engraver Machines

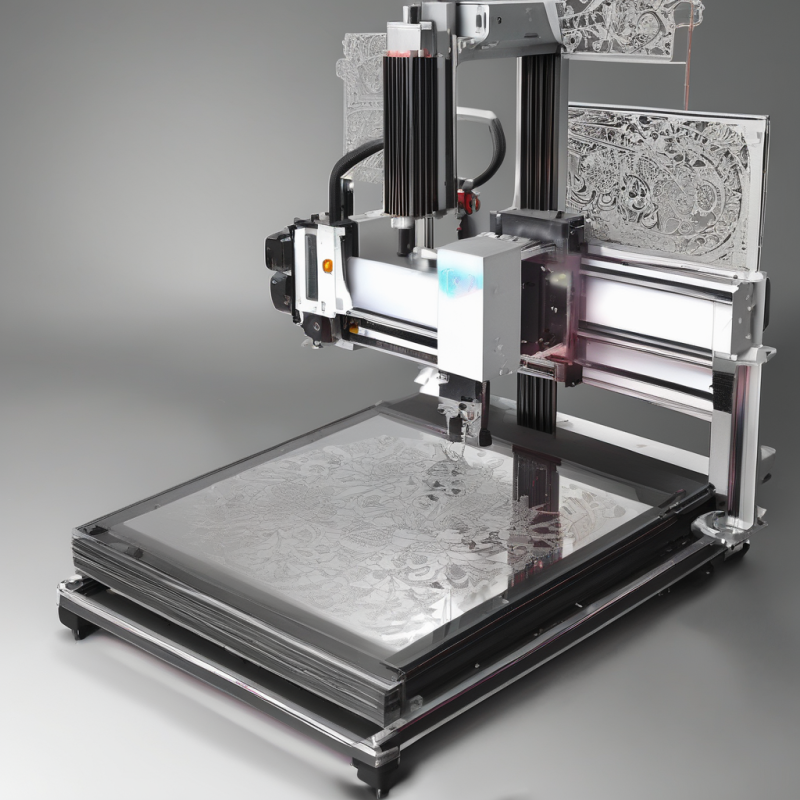

A laser cutter engraver machine is a cutting-edge tool that uses a focused beam of light to cut or engrave materials. The laser beam operates at high intensity, enabling it to precisely cut through various materials such as wood, metal, plastic, glass, and more. Unlike traditional tools, laser machines offer exceptional accuracy, allowing for intricate designs and patterns that are difficult or impossible to achieve manually.

One of the key advantages of these machines is their versatility. They can perform multiple functions, including cutting, engraving, and marking, making them an invaluable asset for a wide range of applications. Whether you’re creating custom signs, crafting jewelry, or manufacturing industrial parts, a laser cutter engraver machine can handle it all with ease.

How does a laser cutter engraver machine work? The process involves directing the laser beam through a series of mirrors and lenses to focus on the material being cut or engraved. The intense heat generated by the laser melts, burns, or vaporizes the material, creating precise cuts or engravings. Modern machines are often equipped with computer numerical control (CNC) technology, allowing for automated operations and complex design capabilities.

Benefits of Using a Laser Cutter Engraver Machine

The advantages of using a laser cutter engraver machine are numerous, making them a must-have tool for many industries. Here are some of the key benefits:

- Precision and Accuracy: Lasers provide unmatched precision, ensuring that every cut or engraving is exact and consistent.

- Versatility: These machines can work with a wide range of materials, making them suitable for various applications.

- Speed: Laser cutting and engraving are much faster than traditional methods, saving time and increasing productivity.

- Durability: The engravings created by laser machines are permanent and resistant to wear and tear.

- Cost-Effective: With minimal material waste and the ability to handle large-scale production, these machines offer excellent value for money.

Why should you invest in a laser cutter engraver machine? If you’re looking to enhance your creative projects, improve efficiency, or expand your business capabilities, this investment is well worth considering. The versatility and precision of these machines make them ideal for both small-scale hobbies and large-scale industrial applications.

Applications of Laser Cutter Engraver Machines

The applications of laser cutter engraver machines are vast and varied, catering to multiple industries and use cases. Here are some common scenarios where these machines shine:

- Creative Design: Artists and designers can use laser machines to create intricate patterns, logos, and custom designs on various materials.

- Jewelry Making: Laser engraving is perfect for adding detailed engravings to jewelry pieces, ensuring each design is unique and precise.

- Signage and Marking: Businesses can produce high-quality signs, plaques, and tags with durable laser-engraved text and logos.

- Industrial Manufacturing: Industrial applications include cutting metal sheets, creating complex parts, and marking components for identification.

- Crafts and Hobbies: Hobbyists can use these machines to create personalized gifts, decorate items, or experiment with new designs.

What industries rely most on laser cutter engraver machines? From manufacturing and automotive to electronics and woodworking, the demand for laser technology spans across multiple sectors. The ability to handle diverse materials and produce high-quality results makes these machines indispensable in modern workflows.

Choosing the Right Laser Cutter Engraver Machine

Selecting the right laser cutter engraver machine depends on your specific needs, budget, and intended use. Here are some factors to consider when making your choice:

- Type of Material: Determine which materials you’ll be working with most frequently. Different machines are optimized for specific types of materials, such as wood, metal, or plastic.

- Powder Size and Power: The power of the laser determines its ability to cut through thicker or tougher materials. Higher-powered lasers are typically better for industrial applications.

- Machine Size: Consider the size of your workspace and the scale of your projects. Smaller machines may be sufficient for personal use, while larger ones are needed for commercial or industrial purposes.

- Software Compatibility: Ensure that the machine is compatible with the software you’ll be using to design and control it. Advanced CNC software can greatly enhance functionality and ease of use.

Where can I find a reliable laser cutter engraver machine? Many online retailers and specialty stores offer high-quality machines tailored to different needs. For example, [insert your website or product name] provides a range of options designed to meet the demands of both hobbyists and professionals.

Maintenance and Safety Tips for Laser Cutter Engraver Machines

To ensure optimal performance and longevity of your laser cutter engraver machine, proper maintenance and safety measures are essential. Here are some tips to keep in mind:

- Cleanliness: Regularly clean the machine to remove dust, debris, and residue that can accumulate during operation.

- Lens Care: Keep the laser lenses free from scratches and dirt to maintain beam quality and prevent damage to your materials.

- Proper Ventilation: Ensure adequate ventilation in your workspace to handle fumes generated during cutting or engraving, especially when working with certain materials like plastics.

- Safety Gear: Always wear appropriate safety gear, including goggles and gloves, to protect yourself while operating the machine.

How often should you service your laser cutter engraver machine? Routine maintenance, such as cleaning and inspecting components, should be done after each use or at least weekly. More extensive servicing may be required every few months depending on usage frequency.

Future Trends in Laser Cutter Engraver Technology

The world of laser technology is constantly evolving, with new innovations emerging to enhance the capabilities and efficiency of laser cutter engraver machines. Some of the trends to watch for include:

- Improved Precision: Advances in laser optics and control systems are leading to even higher levels of precision and detail.

- Automation: Integration with CNC software and automated systems is streamlining operations, reducing manual intervention, and boosting productivity.

- Sustainability: Eco-friendly designs and energy-efficient laser machines are becoming more popular as sustainability becomes a priority in manufacturing.

- AI Integration: Artificial intelligence is being used to optimize laser cutting patterns, reduce waste, and improve overall efficiency.

What does the future hold for laser cutter engraver machines? As technology continues to advance, these machines are likely to become faster, more precise, and capable of handling an even broader range of materials and applications. Stay ahead of the curve by exploring the latest innovations in laser cutting technology.

Frequently Asked Questions

1. How much does a laser cutter engraver machine cost?

The price varies depending on the size, power, and features of the machine. Entry-level models can range from $500 to $2,000, while industrial-grade machines may cost upwards of $10,000 or more.

2. Can I use a laser cutter engraver machine for both cutting and engraving?

Yes, most machines are designed to perform both functions. However, the specific capabilities depend on the type of laser and its power output.

3. Is it difficult to learn how to operate a laser cutter engraver machine?

While some technical knowledge is required, many machines come with user-friendly interfaces and software that make them accessible even for beginners. Training resources are also widely available online.

4. What materials can I cut or engrave with a laser machine?

Common materials include wood, plastic, metal, glass, leather, and acrylic. The specific compatibility depends on the type of laser and its settings.

5. How long does it take to complete a project using a laser cutter engraver machine?

The time required depends on the complexity of the design and the size of the material being cut or engraved. Simple projects may take just a few minutes, while more intricate designs could take hours.

Conclusion

A laser cutter engraver machine is an invaluable tool for anyone looking to bring their creative ideas to life with precision and efficiency. Whether you’re a hobbyist, DIY enthusiast, or professional craftsman, these machines offer unparalleled versatility and performance. By investing in a high-quality laser cutter engraver, you can unlock new possibilities for your projects and achieve results that are both stunning and durable.

If you’re ready to take your crafting skills to the next level, why not explore our range of laser cutter engraver machines today? With the right tools at your fingertips, there’s no limit to what you can create!

A laser cutter engraver machine is a powerful tool that combines cutting and engraving capabilities, enabling users to work with various materials like wood, plastic, metal, and glass. It offers precision and efficiency, making it suitable for both small-scale projects and industrial applications.