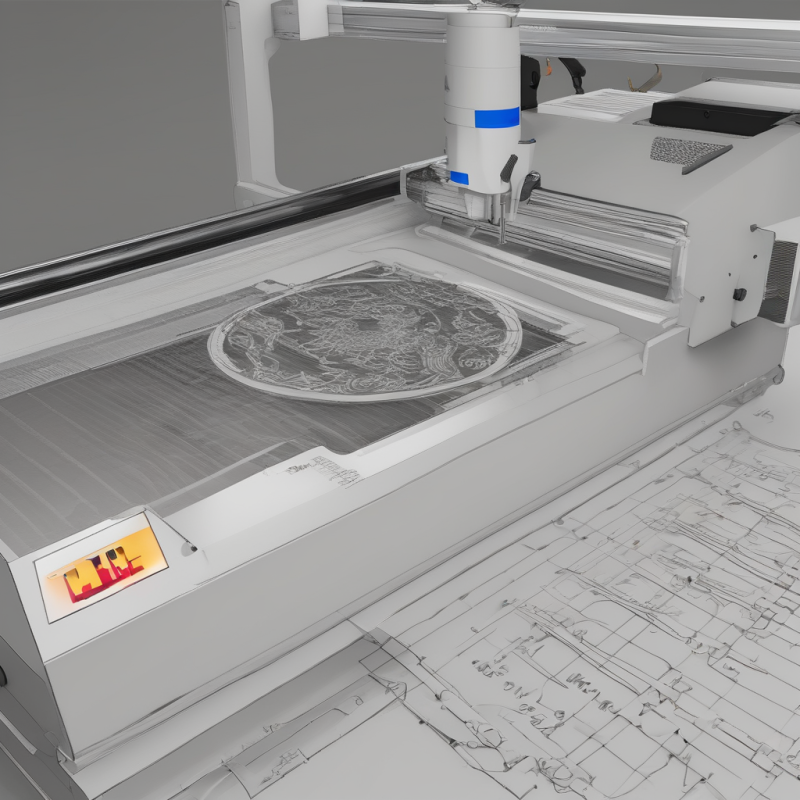

The Ultimate Guide to Laser Cutter Engraver: Precision Meets Innovation

Welcome to the world of precision craftsmanship with the . This cutting-edge tool is revolutionizing industries by combining precision and creativity into one powerful machine. Whether you’re a professional artist, a small business owner, or a hobbyist, this device offers unparalleled versatility and efficiency. In this comprehensive guide, we’ll explore everything you need to know about laser cutter engravers, their applications, benefits, and how to choose the right model for your needs.

What is a Laser Cutter Engraver?

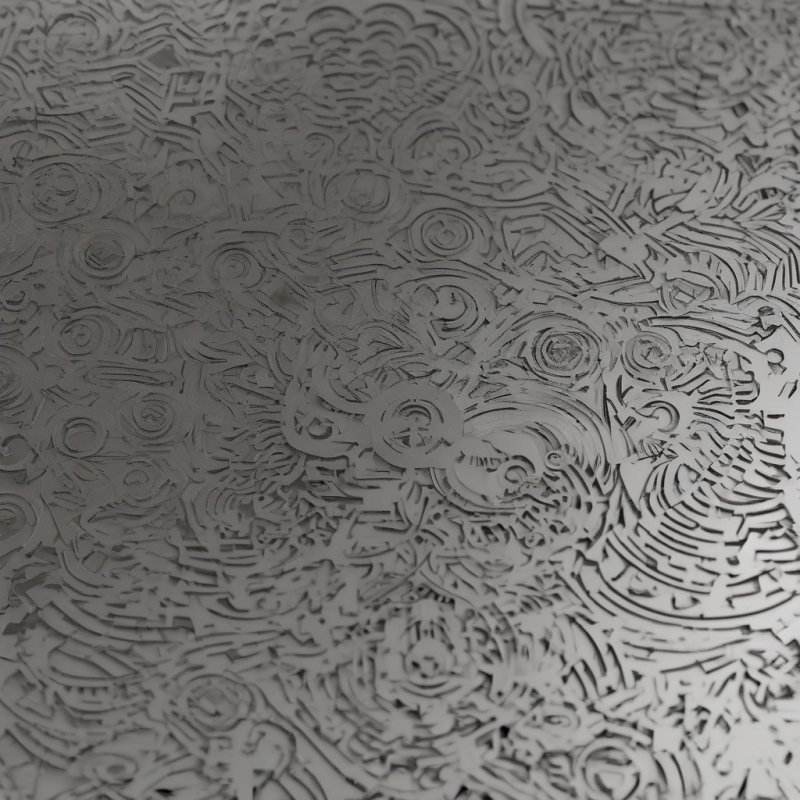

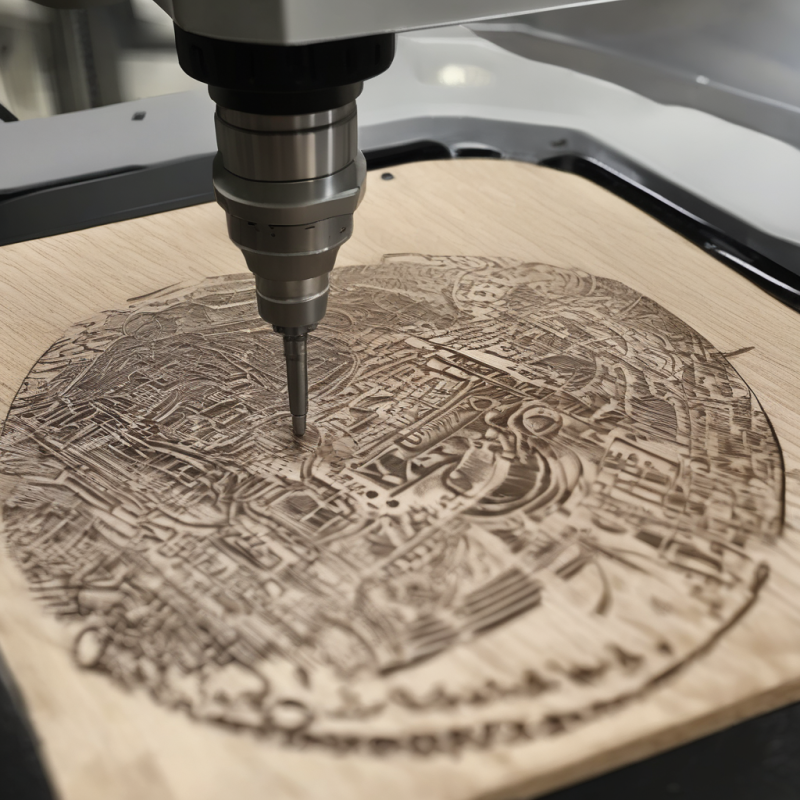

A is a multifunctional tool designed to cut and engrave various materials with high precision. It uses a focused laser beam to create intricate designs, patterns, and text on surfaces such as wood, metal, plastic, and more. Unlike traditional methods that require physical contact, this machine operates with non-contact technology, ensuring minimal material waste and maximum accuracy.

The fiber laser technology used in these engravers is known for its high power, longevity, and low maintenance. This makes it ideal for both small-scale projects and large-volume production. Whether you’re creating custom jewelry, decorative items, or industrial parts, this machine can handle it all with ease.

Key Features of a Laser Cutter Engraver

The comes packed with features that set it apart from traditional tools. Here are some of its standout characteristics:

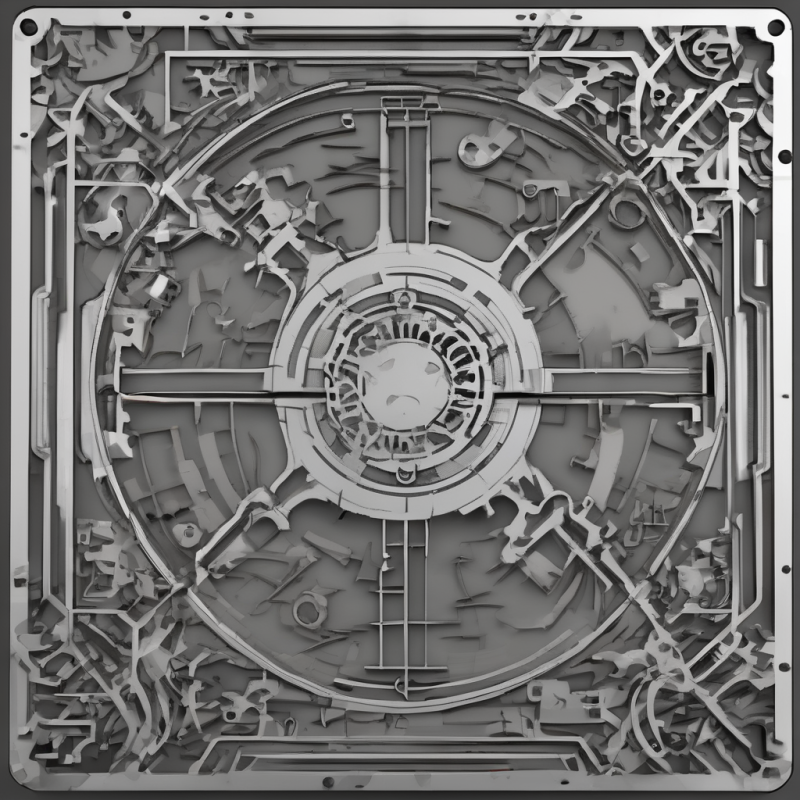

- Precision Cutting and Engraving: The machine can achieve detailed engravings with a precision of up to 0.1 mm, making it perfect for intricate designs.

- Versatile Material Compatibility: It supports a wide range of materials, including wood, metal, plastic, leather, and acrylic.

- User-Friendly Interface: Most models come with an intuitive software interface that allows even beginners to create professional-quality designs.

- High-Speed Processing: The machine can handle large-scale projects quickly, saving you time and increasing productivity.

- Energy Efficiency: Fiber laser technology is known for its low energy consumption, making it an eco-friendly choice.

Applications of a Laser Cutter Engraver

The versatility of the makes it suitable for a wide range of applications. Here are some of the most common uses:

- Crafts and Artwork: Create custom designs, logos, and patterns on wood, metal, or other materials for artistic projects.

- Jewelry Making: Engrave delicate details on jewelry pieces with precision and ease.

- Industrial Prototyping: Use the machine to prototype parts and components quickly and accurately.

- Signage and Marking: Create professional-grade signs, labels, and markings for businesses or personal use.

- Fashion Accessories: Engrave custom designs on leather goods, watches, and other fashion accessories.

If you’re wondering, “What can I do with a laser cutter engraver?” the answer is simple: almost anything! This machine opens up a world of possibilities for both personal and commercial projects.

Benefits of Using a Laser Cutter Engraver

Investing in a comes with numerous benefits that can transform your workflow. Let’s explore some of the key advantages:

- High Precision: The machine delivers unmatched accuracy, ensuring every cut and engraving is perfect.

- Time Efficiency: With its high-speed processing capabilities, you can complete projects faster than with traditional methods.

- Cost-Effective: Minimal material waste and low energy consumption make it a cost-effective solution in the long run.

- Customization: The ability to create custom designs gives you endless creative freedom.

- Durable Performance: Fiber laser technology ensures long-lasting performance with minimal maintenance needs.

These benefits make the a valuable addition to any workshop, studio, or business.

How to Choose the Right Laser Cutter Engraver

Selecting the right depends on your specific needs and budget. Here are some factors to consider:

- Power Output: Higher power output is ideal for cutting thicker materials, while lower power is sufficient for engraving delicate surfaces.

- Material Compatibility: Ensure the machine supports the types of materials you plan to work with.

- Software and Controls: Look for user-friendly software that offers design flexibility and easy control over the machine’s settings.

- Budget: Determine your budget and compare models within that range, keeping in mind the long-term cost savings.

By evaluating these factors, you can find a machine that meets your requirements and helps you achieve professional-quality results.

Maintenance and Safety Tips

To ensure optimal performance and longevity of your , follow these maintenance and safety tips:

- Regular Cleaning: Keep the machine clean to prevent dust buildup, which can affect performance.

- Proper Lubrication: Follow the manufacturer’s guidelines for lubricating moving parts to ensure smooth operation.

- Safety Gear: Always wear safety goggles and gloves when operating the machine to protect yourself from laser exposure and heat.

- Software Updates: Keep the software updated to take advantage of new features and improvements.

By taking good care of your machine, you can enjoy years of reliable performance and high-quality results.

Frequently Asked Questions

What is the difference between a laser cutter and an engraver?

A laser cutter is designed primarily for cutting materials, while an engraver focuses on creating detailed designs and text. However, many modern machines combine both functionalities, allowing you to cut and engrave with the same tool.

Can I use a laser cutter engraver at home?

Absolutely! Many models are designed for home use, making them accessible for hobbyists and small-scale projects. Just ensure you have the necessary safety precautions in place.

How long does it take to learn how to use a laser cutter engraver?

With user-friendly software and intuitive controls, most users can get started within a few hours. Practice and experimentation will help you master advanced techniques over time.

Conclusion

The is a versatile and powerful tool that has revolutionized the way we create and customize products. Its precision, versatility, and efficiency make it an essential addition to any workshop or business. Whether you’re a hobbyist, artist, or industrial professional, this machine offers endless possibilities for bringing your ideas to life.

If you’re ready to take your projects to the next level, consider investing in a . With proper care and use, it will serve you well for years to come. Happy creating!