The Ultimate Guide to Laser Cutter MDF: Precision, Efficiency, and Creativity

When it comes to modern manufacturing and crafting, few tools have revolutionized the industry as much as the laser cutter MDF. This versatile tool is a game-changer for hobbyists, professionals, and businesses alike, offering unparalleled precision and versatility. Whether you’re working on intricate designs or large-scale projects, a laser cutter MDF can handle it all with ease. In this article, we’ll explore everything you need to know about laser cutter MDF, including its benefits, features, applications, and why it’s the perfect choice for your next project.

What is a Laser Cutter MDF?

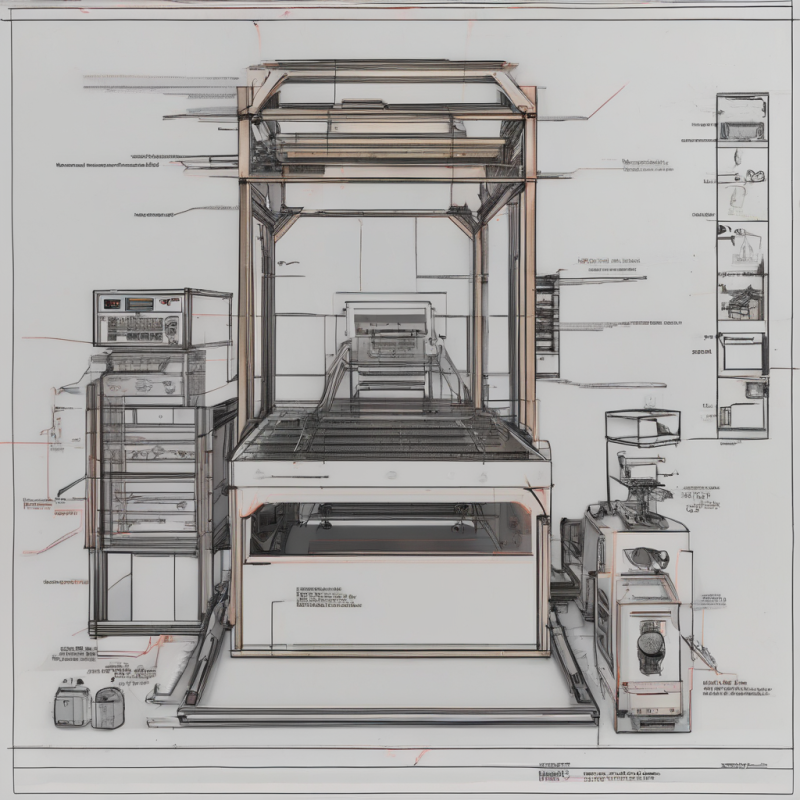

A laser cutter MDF is a cutting-edge tool designed to work with Medium Density Fiberboard (MDF), a popular material in woodworking and crafting. Unlike traditional cutting methods, which often require manual precision and time-consuming processes, a laser cutter uses a focused beam of light to cut through materials with incredible accuracy. This process is not only faster but also produces cleaner, more precise results than conventional tools.

The term “laser cutter MDF” refers specifically to machines that are optimized for cutting MDF sheets, which are widely used in furniture making, signage, decorative items, and more. These machines are equipped with advanced technology, including high-powered CO2 lasers, which are ideal for cutting through materials like wood, plastic, and even some metals. The result is a tool that is both efficient and versatile, capable of handling a wide range of projects.

Benefits of Using a Laser Cutter MDF

There are countless reasons to consider investing in a laser cutter MDF for your next project. Let’s break down some of the key benefits:

- Precision Cutting: Laser cutters are known for their ability to create precise, clean cuts with minimal material waste. This is especially important when working with materials like MDF, which can be tricky to handle with traditional tools.

- Speed and Efficiency: Compared to manual cutting methods, laser cutters significantly reduce the time it takes to complete a project. They are also capable of handling large-scale orders with ease, making them ideal for businesses.

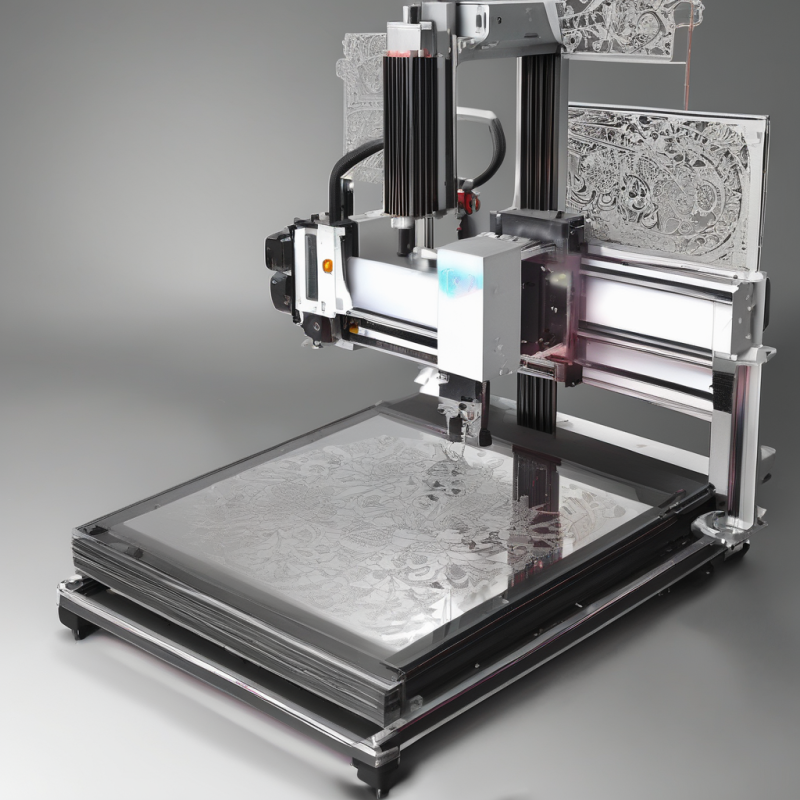

- Versatility: A laser cutter MDF isn’t limited to just cutting; it can also engrave intricate designs into materials, giving you endless creative possibilities. This makes it a must-have tool for artists and crafters alike.

- Cost-Effective: While the initial investment in a laser cutter may seem high, the long-term savings make it worth the price. By reducing material waste and increasing productivity, these machines can pay for themselves over time.

Key Features to Look For in a Laser Cutter MDF

If you’re in the market for a laser cutter MDF, there are several features you should consider before making your purchase. Here are some of the most important ones:

- Laser Power: The power of the laser is one of the most critical factors to consider. A higher wattage laser will be able to cut through thicker materials and work faster, but it may also come with a higher price tag.

- Cutting Speed: Look for machines that offer adjustable cutting speeds, allowing you to optimize performance based on the material and thickness of your project.

- Software Compatibility: A good laser cutter should be compatible with popular design software like Adobe Illustrator, CorelDRAW, or AutoCAD. This ensures that you can easily transfer your designs from your computer to the machine.

- Safety Features: Safety is paramount when working with lasers. Look for machines with features like emergency stop buttons, safety interlocks, and air filtration systems to protect both the operator and the environment.

Applications of Laser Cutter MDF

The laser cutter MDF has a wide range of applications across various industries. Here are just a few examples:

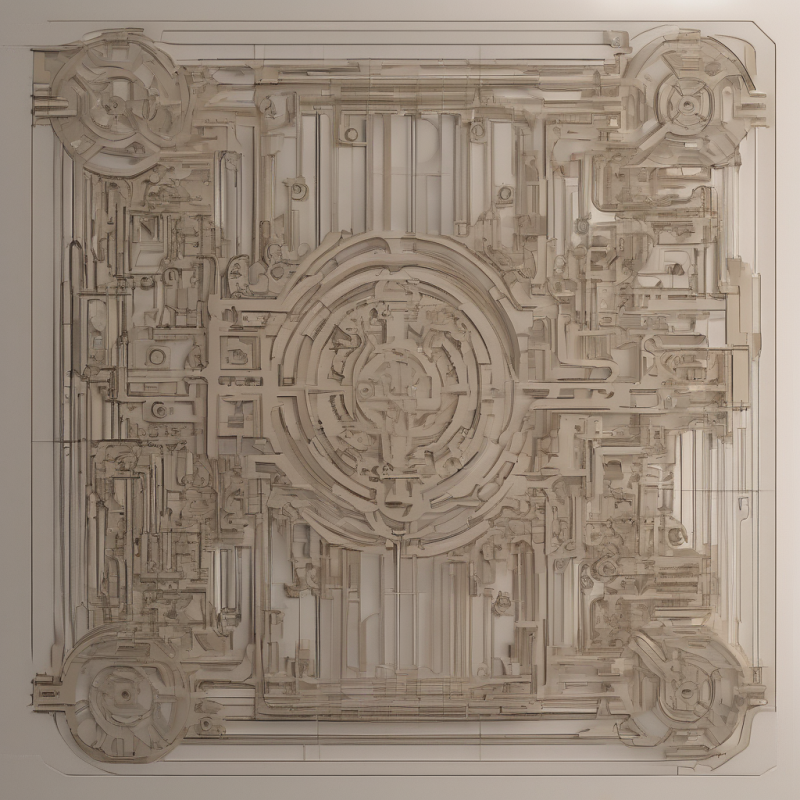

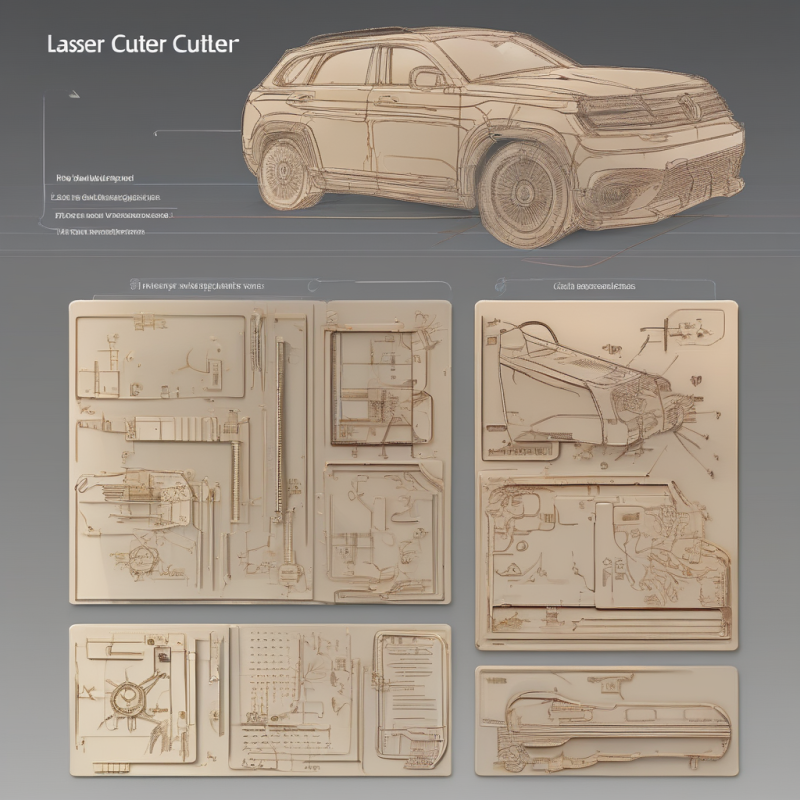

- Furniture Making: From cutting intricate designs into tabletops to creating custom cabinetry, laser cutters are an essential tool for furniture manufacturers.

- Signage and Displays: Laser cutting is ideal for creating signage, including letters, numbers, and decorative elements. It’s also perfect for producing high-quality display cases and shelving units.

- Art and Craft Projects: Artists and crafters can use laser cutters to create detailed designs, patterns, and decorative items. This tool is especially popular among those who work with wood, leather, or metal.

- Prototyping: For businesses in the product development phase, a laser cutter MDF is an invaluable tool for creating prototypes quickly and efficiently.

Why Choose a Laser Cutter MDF Over Traditional Tools?

If you’re wondering whether to invest in a laser cutter or stick with traditional cutting tools, here are some compelling reasons to make the switch:

- Improved Accuracy: Laser cutters offer unparalleled precision, ensuring that every cut is exactly as intended. This reduces the risk of mistakes and minimizes material waste.

- Increased Productivity: With the ability to handle large-scale projects quickly, laser cutters can significantly boost your productivity and output.

- Better Design Flexibility: Laser cutting allows for intricate designs and patterns that would be nearly impossible to achieve with manual tools. This opens up a world of creative possibilities for artists and designers.

- Long-Term Savings: While the upfront cost of a laser cutter may seem high, it’s a one-time investment that can save you money in the long run by reducing material waste and increasing efficiency.

Frequently Asked Questions About Laser Cutter MDF

If you’re new to the world of laser cutters, you might have some questions. Here are answers to some of the most common ones:

- Q: Can a laser cutter MDF be used for materials other than MDF?

- A: Yes! While these machines are optimized for cutting MDF, they can also work with wood, plastic, acrylic, and even some metals. This makes them incredibly versatile.

- Q: Is laser cutting safe?

- A: Yes, as long as you follow proper safety protocols. Look for machines with built-in safety features, and always wear protective eyewear when operating the machine.

- Q: How easy is it to learn how to use a laser cutter MDF?

- A: Most modern laser cutters are designed with user-friendly interfaces and come with comprehensive training materials. With a little practice, you’ll be able to master the basics in no time.

Conclusion

The laser cutter MDF is an indispensable tool for anyone looking to take their crafting or manufacturing projects to the next level. Its precision, versatility, and efficiency make it a must-have addition to any workshop or studio. Whether you’re a seasoned professional or just starting out, investing in a laser cutter can open up a world of possibilities and help you achieve your creative goals with ease.

If you’re ready to take the plunge and purchase your own laser cutter MDF, be sure to check out our top recommendations. You won’t regret it!