The Ultimate Guide to Laser Engraving Machines for Metal

Are you looking for a precise and efficient way to engrave metal? If so, you’ve probably come across the term laser engraver for metal. But what exactly is it, and how can it benefit your projects? In this article, we’ll explore everything you need to know about laser engraving machines for metal, including their features, applications, advantages, and more. Let’s dive in!

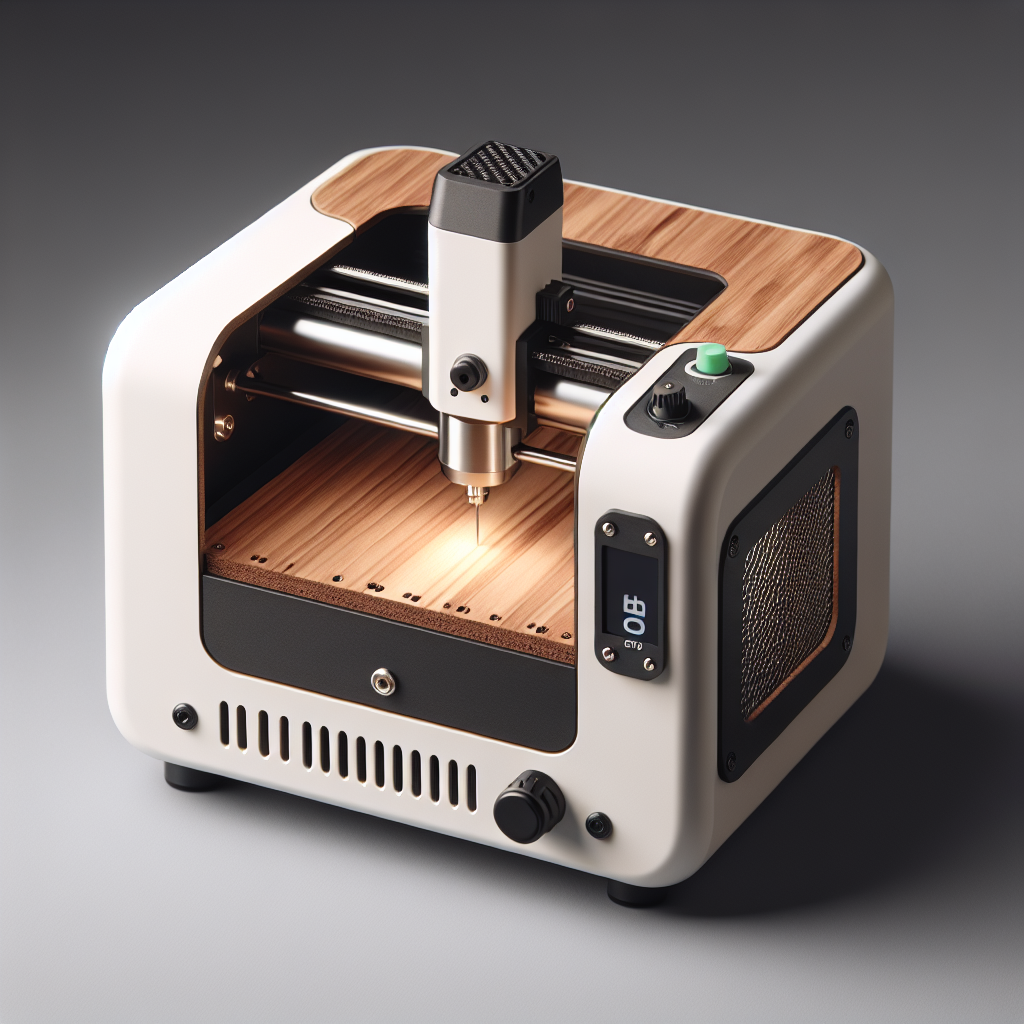

What Is a Laser Engraver for Metal?

A laser engraver for metal is a machine that uses high-powered lasers to etch or cut intricate designs onto metallic surfaces. Unlike traditional engraving methods, laser engraving offers unparalleled precision and versatility. Whether you’re working on jewelry, automotive parts, or industrial components, this tool can handle it all with ease.

One of the key advantages of a laser engraver for metal is its ability to work on a wide range of materials. From stainless steel to aluminum, titanium, and even gold, these machines are designed to handle various metals with precision. Plus, they’re ideal for both small-scale projects and large industrial applications.

Why Use a Laser Engraver for Metal?

If you’ve ever wondered why professionals prefer laser engravers over traditional tools, here are some compelling reasons:

- Precision: Laser engraving machines offer micron-level accuracy, ensuring that even the most detailed designs are rendered perfectly.

- Speed: Compared to manual engraving, laser engravers significantly reduce production time while maintaining quality.

- Versatility: These machines can handle a variety of metals and materials, making them suitable for diverse industries.

- Cost-Effective: Over time, laser engravers save money by reducing material waste and minimizing the need for rework.

These benefits make laser engravers for metal a must-have tool for any serious metalworker or artist.

Features of a Laser Engraver for Metal

Browse through the features of , and you’ll notice several standout capabilities:

- High-Power Laser: Equipped with powerful lasers, these machines can handle thick or tough metals with ease.

- CNC Control: Computer Numerical Control allows for precise programming of designs and patterns.

- User-Friendly Interface: Modern laser engravers come with intuitive software that simplifies the design process.

- Dust Extraction System: Built-in systems ensure a clean workspace by removing debris during operation.

- Multiple Processing Modes: Capable of both engraving and cutting, these machines offer versatility for various projects.

These features make laser engravers not only efficient but also easy to use, even for those who are new to the technology.

Applications of Laser Engraving in Metalworking

The applications of laser engravers for metal are vast and varied. Here are some of the most common uses:

- Jewelry Making: Create intricate designs on wedding rings, pendants, and other precious metals.

- Automotive Industry: Engrave custom logos, serial numbers, or decorative patterns on car parts.

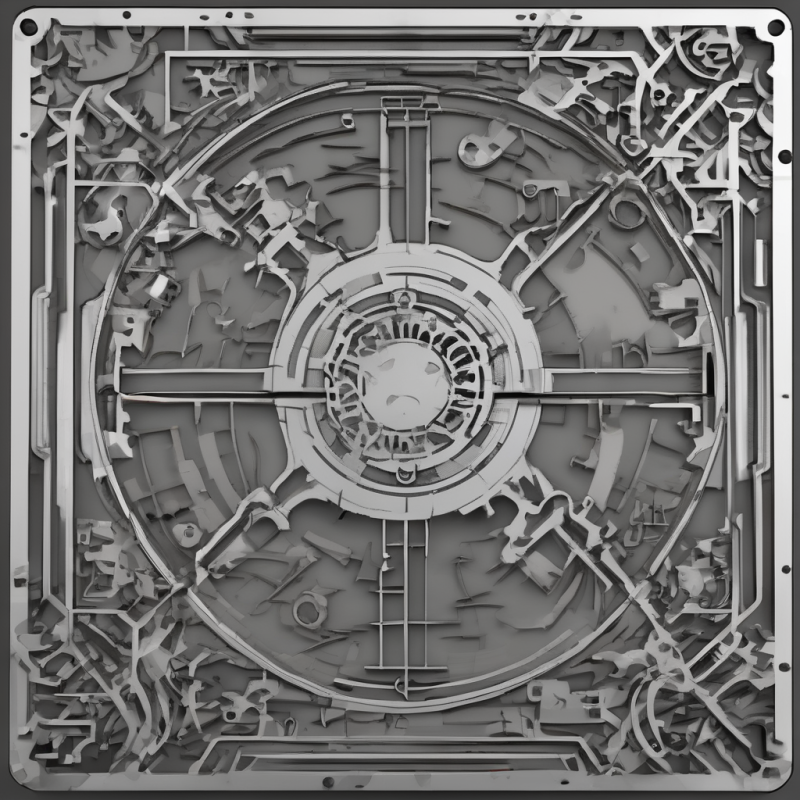

- Industrial Manufacturing: Use laser engravers to mark components with barcodes, QR codes, or identification numbers.

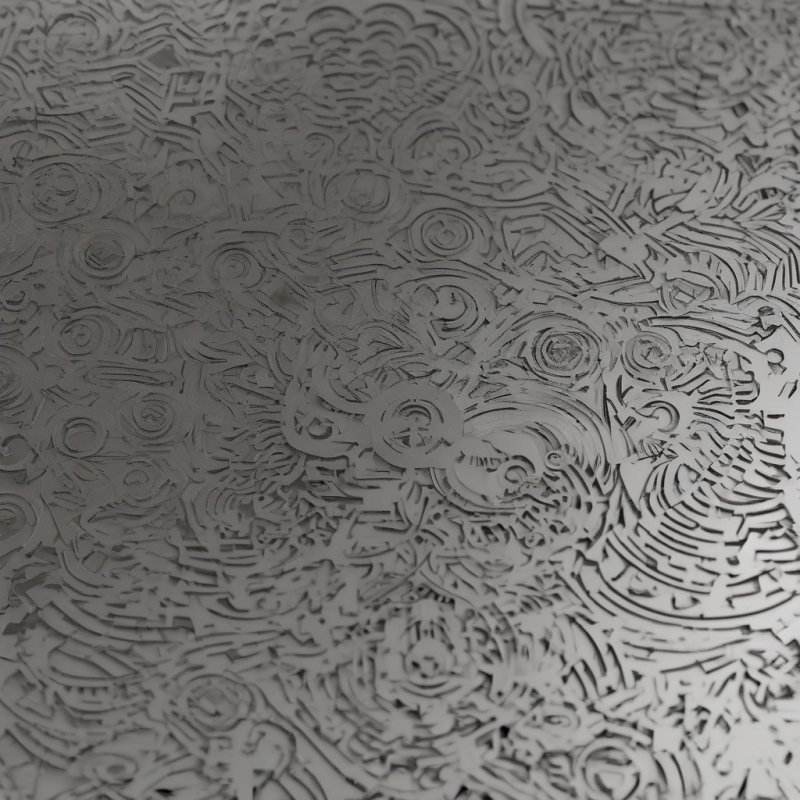

- Art and Design: Produce unique metal art pieces, sculptures, and custom decorations.

- Medical Devices: Engrave precise markings on surgical instruments and medical equipment.

No matter the industry, a laser engraver for metal can help you achieve professional-grade results with minimal effort.

Advantages of Laser Engraving Over Traditional Methods

Compared to traditional engraving methods like mechanical or chemical etching, laser engraving offers several advantages:

- Better Precision: Lasers can create intricate details that are impossible with manual tools.

- Faster Processing: Laser engravers complete tasks in a fraction of the time required by traditional methods.

- Non-Contact Process: Since lasers don’t physically touch the material, there’s no risk of damaging the metal during engraving.

- Eco-Friendly: Laser engraving produces less waste and doesn’t require harmful chemicals.

- Cost Savings: Over time, laser engravers reduce material costs and minimize labor expenses.

These benefits make laser engraving a preferred choice for industries where precision, speed, and efficiency are paramount.

How to Choose the Right Laser Engraver for Metal

If you’re in the market for a laser engraver for metal, there are several factors to consider:

- Laser Power: Higher power lasers can handle thicker metals and faster processing speeds.

- Software Compatibility: Ensure the machine supports popular design software like AutoCAD or Illustrator.

- Build Quality: Look for machines with durable construction to withstand long-term use.

- Dust Management: A good dust extraction system is essential for maintaining a clean workspace.

- Customer SupportEnsure the manufacturer offers reliable customer service and technical support.

By evaluating these factors, you can choose a laser engraver for metal that best fits your needs and budget.

Maintenance Tips for Laser Engravers

To keep your laser engraver for metal in optimal condition, follow these maintenance tips:

- Clean Regularly: Remove dust and debris after each use to prevent buildup.

- Inspect Lasers: Check the laser optics regularly for dirt or damage.

- Calibrate Often: Periodically recalibrate the machine to ensure accurate engraving.

- Update Software: Keep the software updated to access new features and improvements.

- Replace Consumables: Replace items like filters, lenses, and nozzles as needed.

Proper maintenance ensures your laser engraver remains efficient and produces high-quality results for years to come.

Frequently Asked Questions About Laser Engravers for Metal

Here are some common questions about laser engravers for metal:

- Q: Can I use a laser engraver on all types of metal?

A: Yes, but different metals may require adjustments in power and focus. Always test on scrap material first. - Q: Is laser engraving safe?

A: When used properly with safety precautions, yes. Wear protective eyewear and ensure good ventilation. - Q: How long does it take to learn how to use a laser engraver?

A: With modern software and user-friendly interfaces, you can start using one in just a few hours. - Q: Can I engrave intricate designs with a laser?

A: Absolutely. Lasers are capable of creating highly detailed patterns that are impossible with traditional methods.

If you have more questions, consult the manufacturer or reach out to experienced users for guidance.

Conclusion

A laser engraver for metal is a powerful tool that offers precision, versatility, and efficiency. Whether you’re working in jewelry design, automotive manufacturing, or medical device production, laser engraving can help you achieve professional-grade results with minimal effort. By choosing the right machine and maintaining it properly, you can unlock new possibilities in your creative projects.

So why wait? Invest in a laser engraver for metal today and take your craftsmanship to the next level!

The Power of Laser Engraving: Transforming Metalworking with Precision and Efficiency

In the ever-evolving world of manufacturing and design, precision and creativity go hand in hand. Among the tools that have revolutionized these fields is the laser engraver for metal—a device that combines cutting-edge technology with artistic flair to produce intricate designs and markings on metal surfaces. This article explores the capabilities, applications, and benefits of laser engravers, offering insights into why they are indispensable in modern metalworking.

Understanding Laser Engraving Technology

Laser engraving is a non-contact process that uses focused light beams to etch or cut materials. Unlike traditional methods like mechanical or chemical etching, laser engraving offers unparalleled precision and speed. The technology involves directing a high-powered laser at the surface of the metal, creating permanent markings with exceptional detail.

Key Features of Laser Engravers for Metal

Modern laser engravers come equipped with advanced features that enhance their functionality:

- CNC Control: Computer Numerical Control allows users to program precise designs and patterns, ensuring consistency across multiple pieces.

- User-Friendly Software: Intuitive design software simplifies the creation of complex patterns and engravings, making it accessible even for those new to laser technology.

- Dust Extraction System: Built-in systems manage debris efficiently, maintaining a clean and safe workspace.

- Multiple Processing Modes: Capable of both engraving and cutting, these machines offer versatility for various projects.

Applications Across Industries

The versatility of laser engravers makes them indispensable in numerous industries:

- Jewelry Making: Craft intricate designs on precious metals like gold and silver, creating unique pieces such as wedding rings and pendants.

- Automotive Industry: Engrave custom logos, serial numbers, or decorative patterns on car parts, enhancing both functionality and aesthetics.

- Industrial Manufacturing: Mark components with barcodes, QR codes, and identification numbers for traceability and quality control.

- Art and Design: Produce one-of-a-kind metal art pieces and sculptures, pushing the boundaries of creativity.

- Medical Devices: Engrave precise markings on surgical instruments and medical equipment, ensuring clarity and precision.

Advantages Over Traditional Methods

Laser engraving stands out for several reasons:

- Precision: Capable of creating intricate details that manual tools cannot achieve.

- Speed: Completes tasks faster than traditional methods, enhancing productivity.

- Non-Contact Process: Eliminates the risk of damaging the material during engraving.

- Eco-Friendly: Produces less waste and avoids harmful chemicals, aligning with sustainable practices.

Choosing the Right Laser Engraver

When selecting a laser engraver for metal, consider:

- Laser Power: Higher power accommodates thicker metals and faster processing.

- Software Compatibility: Ensure compatibility with design software like AutoCAD or Illustrator.

- Build Quality: Opt for durable construction to ensure longevity.

- Dust Management: Effective systems are crucial for maintaining a clean workspace.

Maintenance Tips

To keep your laser engraver in top condition:

- Clean Regularly: Remove dust and debris after each use.

- Inspect Lasers: Check optics regularly for dirt or damage.

- Calibrate Often: Recalibrate to maintain accuracy.

- Update Software: Keep software current for optimal performance.

Frequently Asked Questions

- Q: Can I use a laser engraver on all types of metal?

- – Yes, but adjustments may be needed based on the metal type. Test on scrap material first.

- Q: Is laser engraving safe?

- – Safe when proper precautions are taken, including protective eyewear and good ventilation.

- Q: How long does it take to learn to use a laser engraver?

- – With user-friendly interfaces, you can start using one within a few hours.

- Q: Can I engrave intricate designs with a laser?

- – Absolutely, offering details impossible with traditional methods.

Conclusion

Laser engravers for metal are indispensable tools in modern craftsmanship. They offer precision, versatility, and efficiency across industries, from jewelry to medical devices. By investing in this technology and maintaining it properly, you can elevate your projects to new heights of creativity and quality.

Embrace the future of metalworking with a laser engraver—unlock endless possibilities and take your craft to unprecedented levels today!