The Ultimate Guide to Laser Engraving Machines: Precision, Efficiency, and Creativity

Laser engraving machines have revolutionized the way we create intricate designs, patterns, and text on various materials. These machines are not only efficient but also offer unparalleled precision, making them indispensable in industries such as jewelry, signage, electronics, and more. If you’re considering investing in a laser engraving machine, it’s essential to understand how they work, their applications, and the benefits they bring to your projects. In this article, we’ll explore everything you need to know about laser for engraving machine technology and how it can transform your creativity into reality.

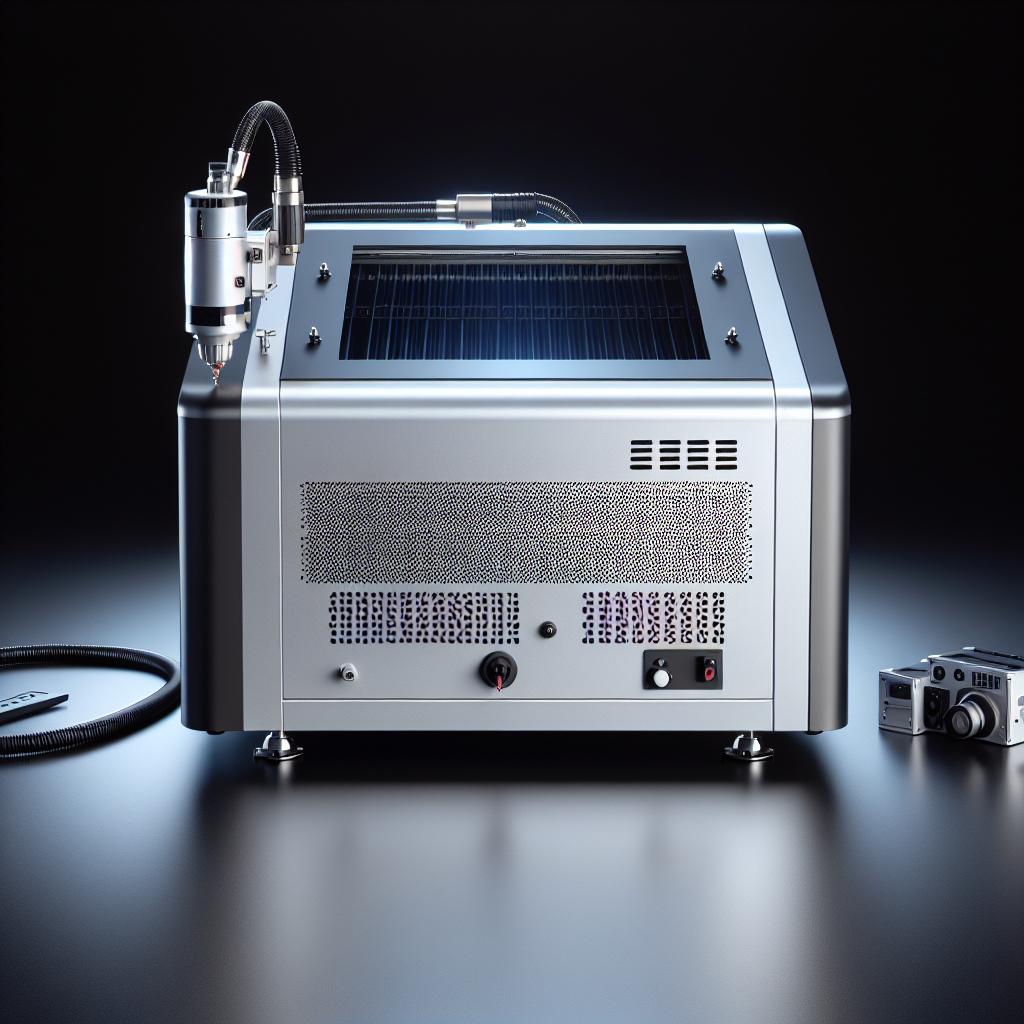

What is a Laser Engraving Machine?

A laser engraving machine uses a focused beam of light to etch or cut designs, patterns, or text onto materials like wood, metal, plastic, glass, and more. Unlike traditional methods, which often require physical contact with the material, laser engraving is a non-contact process. This makes it ideal for delicate or hard-to-reach surfaces. The machine uses a high-powered laser to remove material layer by layer, creating precise and durable markings.

The laser for engraving machine is controlled by a computer or CNC (Computer Numerical Control) system, allowing users to input designs and patterns with ease. This level of automation ensures consistency and accuracy in every project, whether it’s a small batch or a large-scale production.

Applications of Laser Engraving Machines

Laser engraving machines are incredibly versatile and can be used in a wide range of industries. Here are some of the most common applications:

- Jewelry Making: Engraving intricate designs on rings, necklaces, and other precious metals.

- Signage: Creating custom signs, plaques, and nameplates with sharp, permanent text and graphics.

- Electronics: Marking circuit boards, components, and devices with precise details.

- Medical Devices: Engraving medical equipment and implants with patient-specific information.

- Furniture: Adding decorative patterns or personal engravings to wood surfaces.

The versatility of laser engraving machines makes them a valuable tool for both small-scale hobbyists and large industrial operations. Whether you’re creating custom gifts, producing marketing materials, or manufacturing high-tech components, these machines can handle it all.

How Does a Laser Engraving Machine Work?

To understand the capabilities of a laser engraving machine, let’s break down how it works:

- Laser Source: The machine generates a high-powered laser beam, typically using CO2 or fiber lasers depending on the material being engraved.

- Focusing Optics: The laser beam is focused through lenses to create an intense, pinpoint beam capable of melting, burning, or vaporizing the material surface.

- CNC Control: A computer or CNC system directs the laser’s movements based on pre-designed patterns or text. This ensures precise placement and alignment of each engraving.

- Material Removal: As the laser beam interacts with the material, it removes layers to create the desired design. The depth and intensity of the laser can be adjusted for different effects.

This process allows for an incredible level of detail and customization, making laser engraving machines a favorite among artists, engineers, and manufacturers alike.

Advantages of Using a Laser Engraving Machine

There are numerous benefits to using a laser engraving machine over traditional methods:

- Precision and Accuracy: The laser’s focused beam ensures that every detail is captured with pinpoint accuracy, even on complex designs.

- Versatility: Capable of working with a wide range of materials, from softwoods to steel, these machines are incredibly adaptable.

- Speed and Efficiency: Once programmed, the machine can complete tasks quickly, reducing production time and costs.

- Durability: Laser engravings are permanent and resistant to wear, making them ideal for long-lasting products.

- Non-Contact Process: No physical pressure is applied to the material, minimizing the risk of damage or distortion.

These advantages make laser engraving machines a top choice for businesses looking to enhance their production capabilities and deliver high-quality products to their customers.

Frequently Asked Questions About Laser Engraving Machines

If you’re new to laser engraving technology, you might have some questions. Let’s address the most common ones:

- What materials can I engrave with a laser machine?

The laser for engraving machine can work with various materials, including wood, metal, plastic, glass, and even some types of stone. The specific material compatibility depends on the type of laser used (CO2 or fiber). - Is laser engraving safe?

Yes, when operated correctly, laser engraving machines are safe. However, it’s important to follow safety guidelines, such as wearing protective eyewear and ensuring proper ventilation in the workspace. - How easy is it to learn how to use a laser engraving machine?

Most machines come with user-friendly software that simplifies the design and programming process. With some practice, even beginners can create stunning engravings.

Maintenance and Care for Laser Engraving Machines

To ensure your laser engraving machine operates at peak performance, regular maintenance is essential. This includes cleaning the optics, checking the alignment of the laser beam, and replacing consumable parts as needed. Proper care will extend the lifespan of your machine and maintain its precision over time.

Conclusion

Laser engraving machines are a game-changer for anyone looking to create detailed, durable, and customized designs. Their versatility, precision, and efficiency make them an invaluable tool in both artistic and industrial applications. Whether you’re a hobbyist or a business owner, investing in a high-quality laser for engraving machine can open up endless possibilities for your projects.

If you’re ready to take your creativity to the next level, it’s time to explore the world of laser engraving. With the right machine and a little practice, you’ll be able to produce stunning results that impress clients and customers alike!