The Ultimate Guide to Small Metal Laser Cutters

Laser cutting technology has revolutionized the way we shape and design materials, offering precision and efficiency that traditional methods simply cannot match. Among the many laser cutting tools available, the small metal laser cutter stands out as a versatile and compact solution for hobbyists, craftsmen, and small-scale manufacturers alike. In this article, we will explore what a small metal laser cutter is, its benefits, how it works, and how you can make the most of this innovative tool.

What Is a Small Metal Laser Cutter?

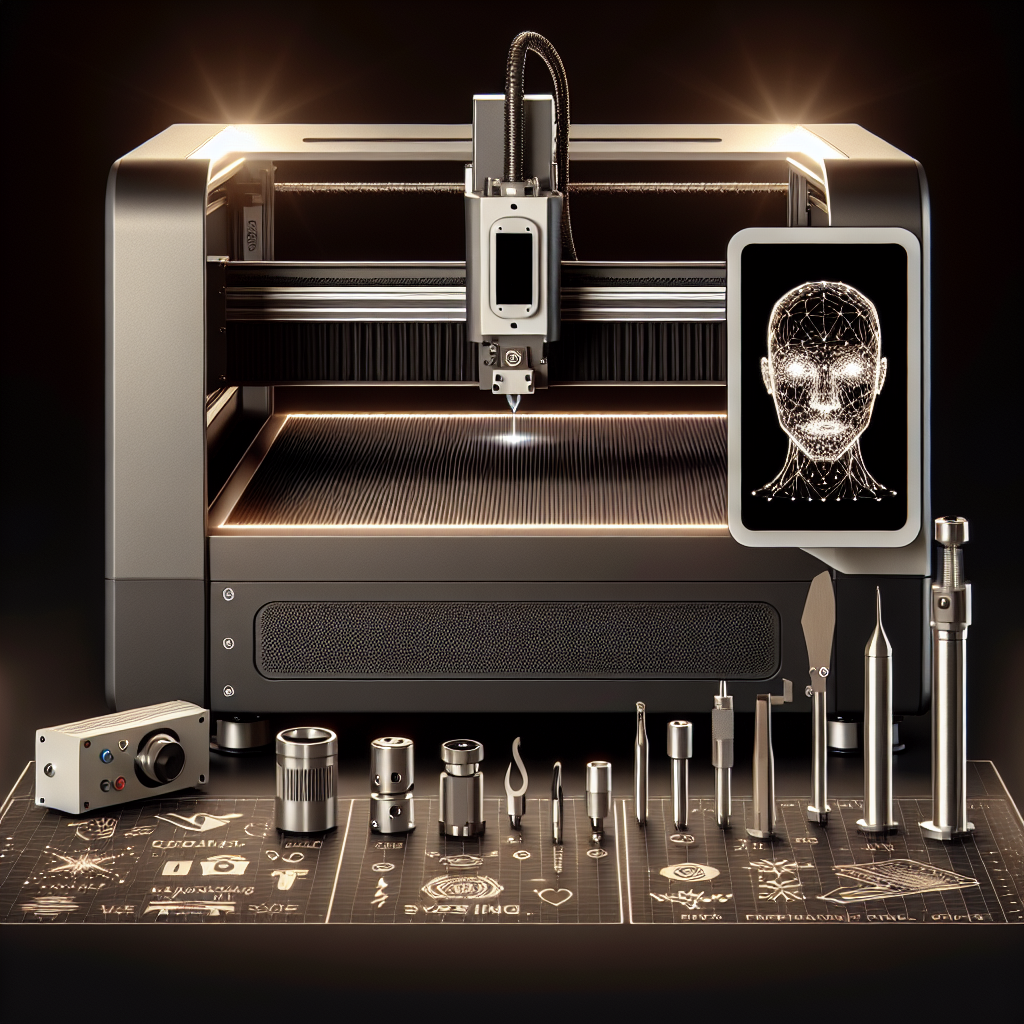

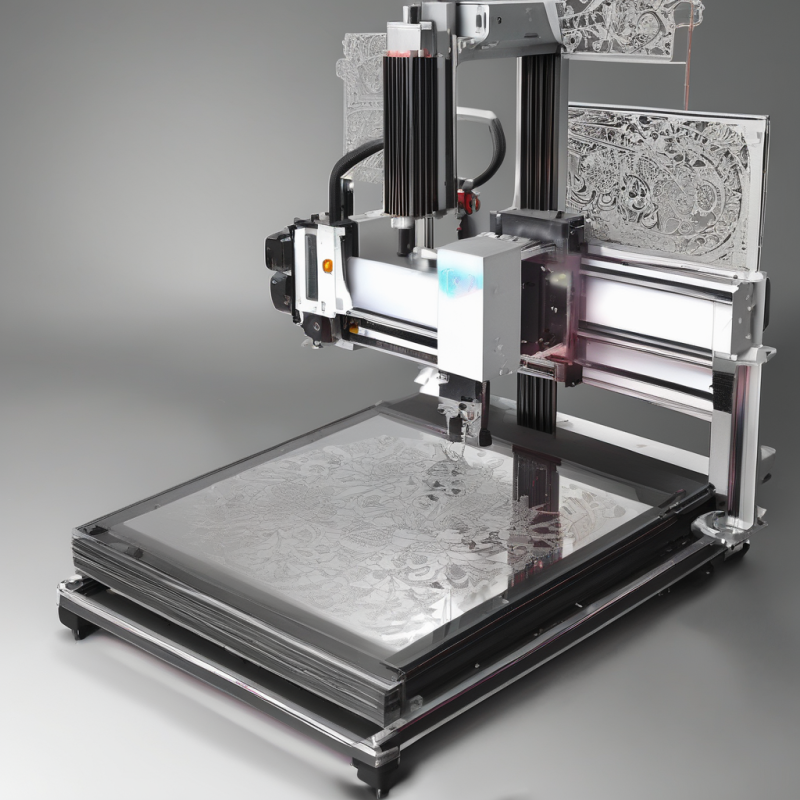

A small metal laser cutter is a compact machine designed to cut and engrave various materials, including metal, with extreme precision. Unlike larger industrial laser cutters, these devices are tailored for home or small workshop use, making them accessible to individuals who may not have the space or budget for heavy-duty machinery. The device uses a focused laser beam to melt, burn, or vaporize material, leaving behind clean and precise cuts.

One of the key features of a small metal laser cutter is its ability to work with multiple materials, including steel, stainless steel, aluminum, brass, and even non-metallic materials like wood and plastic. This versatility makes it an invaluable tool for a wide range of applications, from creating custom jewelry to prototyping small mechanical parts.

The Benefits of Using a Small Metal Laser Cutter

Before diving into the specifics of how a small metal laser cutter works, let’s first consider why you might want to invest in one. Here are some of the primary benefits:

- Precision and Accuracy: The laser beam is highly focused, ensuring clean and precise cuts with minimal material waste.

- Versatility: Capable of cutting a wide range of materials, including metal, wood, plastic, and more.

- Compact Design: Perfect for home workshops or small-scale production environments where space is limited.

- Cost-Effective: Compared to larger industrial machines, these devices are more affordable and require less energy to operate.

- User-Friendly: Many models come with intuitive software and interfaces, making them easy to use even for beginners.

These benefits make a small metal laser cutter an excellent choice for anyone looking to bring professional-level precision into their home or small workshop. But how exactly does this technology work?

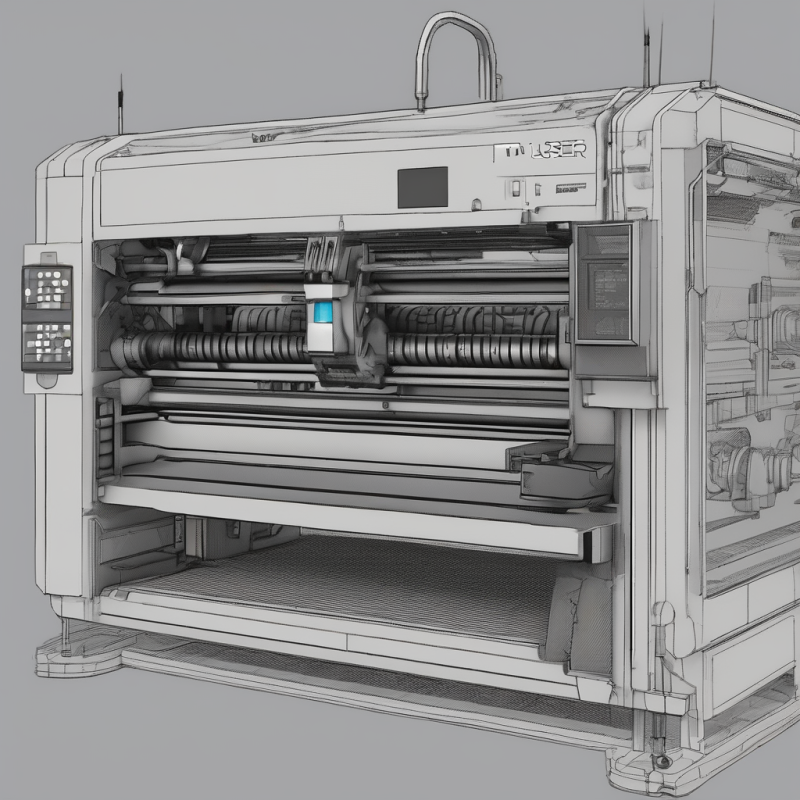

How Does a Small Metal Laser Cutter Work?

The operation of a small metal laser cutter relies on the principles of laser ablation, where a high-powered laser beam is directed at the material being cut. The intense heat generated by the laser causes the material to melt, burn, or vaporize, creating a clean and precise cut. The process involves several key components:

- Laser Source: This is the heart of the machine, producing the focused beam of light that does the cutting.

- Focusing Lens: The lens concentrates the laser beam to a pinpoint, ensuring maximum intensity at the point of contact.

- CNC Control System: Most modern small metal laser cutters are equipped with CNC (Computer Numerical Control) systems that allow for precise programming and automation of cutting patterns.

- Motion System: This includes the X, Y, and Z axes that move the laser head or the material to create intricate designs and shapes.

The machine is typically controlled via software that allows users to design or import patterns, which are then translated into cutting instructions for the CNC system. The result is a highly efficient and accurate cutting process that can handle even the most complex designs.

Applications of Small Metal Laser Cutters

The versatility of a small metal laser cutter means it can be used in a wide variety of applications. Here are some common uses:

- Jewelry Making: Create intricate designs and patterns on precious metals like gold, silver, and platinum.

- Crafts and Artwork: Engrave or cut custom designs into metal, wood, or plastic for artistic projects.

- Prototyping: Quickly produce prototypes of small mechanical parts or components.

- Signage and Advertising: Cut letters and symbols from metal sheets to create customized signs.

- Home Improvement: Customize metal fixtures, handles, and other decorative elements for your home.

These applications highlight the versatility of a small metal laser cutter, making it a valuable tool for both creative and practical projects. Whether you’re a hobbyist looking to explore new artistic possibilities or a small business owner seeking an efficient production method, this machine has something to offer.

Choosing the Right Small Metal Laser Cutter

If you’re considering purchasing a small metal laser cutter, there are several factors to keep in mind. First and foremost, consider your specific needs and the types of materials you plan to work with. For example, if you primarily intend to cut thicker metals, you’ll need a machine with a higher power output compared to someone who focuses on thinner materials or non-metallic substances.

Another important consideration is the size and weight of the machine. While these devices are designed to be compact, they still require adequate space for operation. Additionally, look into the software and controls provided—user-friendly interfaces and robust design tools can make a significant difference in your experience with the machine.

Finally, don’t overlook the importance of customer support and after-sales service. A reliable manufacturer or seller can provide valuable assistance if you encounter any issues or need guidance on optimizing your cuts. For those looking for a high-quality option, the is an excellent choice. With its advanced features and user-friendly design, it’s ideal for both beginners and experienced users alike.

Tips for Getting the Most Out of Your Small Metal Cutter

To ensure you get the best results from your small metal laser cutter, here are some tips to keep in mind:

- Practice on Scrap Material: Before tackling your final project, practice your cuts on scrap material to perfect your technique and settings.

- Use the Right Settings: Adjust the laser power, speed, and focus according to the type and thickness of the material you’re cutting.

- Maintain Proper Alignment: Regularly check and adjust the alignment of your laser head to ensure precise cuts.

- Keep It Clean: Dust and debris can interfere with the machine’s performance, so clean it regularly and keep the work area tidy.

By following these tips, you can maximize the efficiency and longevity of your small metal laser cutter, ensuring that it remains a reliable tool for years to come.

Frequently Asked Questions About Small Metal Laser Cutters

If you’re new to the world of laser cutting, you might have some questions about how these machines work and what they can do. Here are answers to some common queries:

- Can I cut thick metals with a small metal laser cutter?

While most small metal laser cutters are capable of cutting through metal, the thickness you can achieve depends on the machine’s power output. Higher wattage machines are better suited for thicker materials. - Is it safe to use at home?

Yes, but like any power tool, proper safety precautions should be taken, such as wearing protective eyewear and ensuring adequate ventilation in your workspace. - Do I need special software to operate it?

Most machines come with their own software or are compatible with popular design programs like AutoCAD. However, some models may require additional software for advanced features.

By addressing these common concerns upfront, you can make an informed decision about whether a small metal laser cutter is right for your needs.

The Future of Laser Cutting Technology

As technology continues to evolve, so does the capabilities of small metal laser cutters. Innovations such as higher-powered lasers, more intuitive software, and improved CNC systems are making these machines even more accessible and efficient for users at all levels.

In addition, advancements in artificial intelligence and machine learning are opening up new possibilities for automated cutting and design optimization. As these technologies become more mainstream, we can expect to see small metal laser cutters becoming even more versatile and user-friendly.

Conclusion

A small metal laser cutter is a powerful tool that combines precision, versatility, and ease of use, making it an excellent choice for hobbyists, craftsmen, and small-scale manufacturers. Whether you’re creating custom jewelry, prototyping mechanical parts, or simply exploring your creative side, this machine has the potential to transform your projects into something truly special.

If you’re ready to take the plunge into the world of laser cutting, consider investing in a high-quality small metal laser cutter such as the . With its advanced features and user-friendly design, it’s sure to become an invaluable part of your toolkit.