Title: Mastering Jewelry Laser Cutting: A Comprehensive Guide

Are you intrigued by the precision and artistry of laser cutting in jewelry design? If so, you’re likely wondering how a jewelry laser cutter can revolutionize your craft. This article delves into the world of jewelry laser cutting, exploring its benefits, applications, and considerations to help you make informed decisions.

Understanding Jewelry Laser Cutting

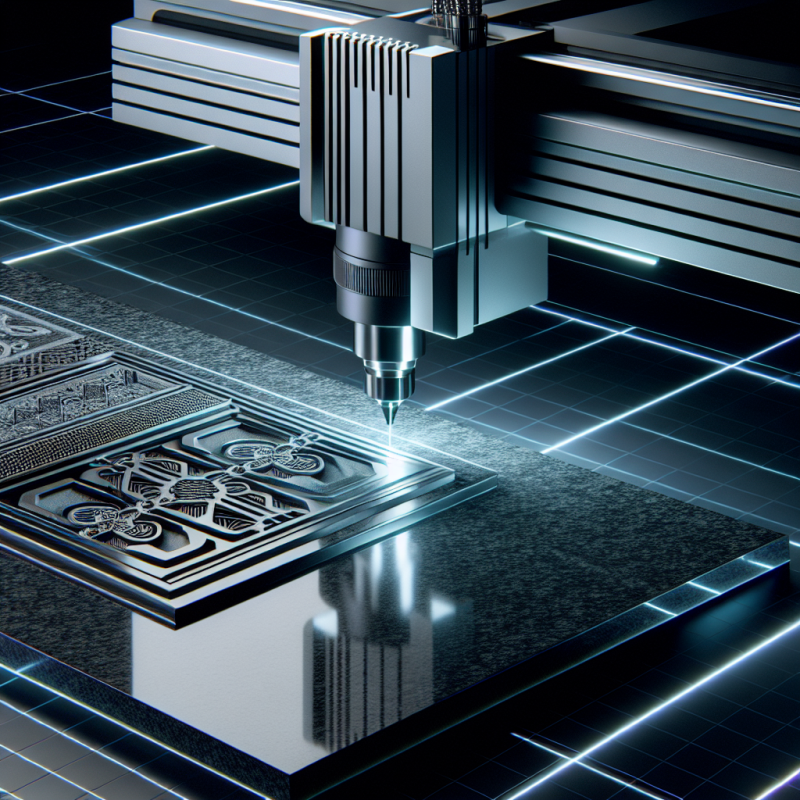

Jewelry laser cutting is a cutting-edge technology that uses high-powered lasers to create intricate designs on various materials. Unlike traditional methods, this process offers unparalleled precision, making it ideal for delicate jewelry pieces. Whether shaping metal, plastic, or stone, the jewelry laser cutter ensures intricate details and clean cuts every time.

Benefits of a Jewelry Laser Cutter

The advantages of using a jewelry laser cutter are manifold:

- Precision: Capable of cutting intricate designs with micrometer accuracy, ideal for complex jewelry patterns.

- Speed: Reduces production time by enabling rapid prototyping and mass production without compromising quality.

- Versatility: Suitable for a wide range of materials, from gold and silver to titanium and resin.

- Cost-Effective: Lowers material waste compared to traditional methods, enhancing profitability.

- Eco-Friendly: Minimizes waste and reduces the need for harmful chemicals used in other cutting processes.

How Does a Jewelry Laser Cutter Work?

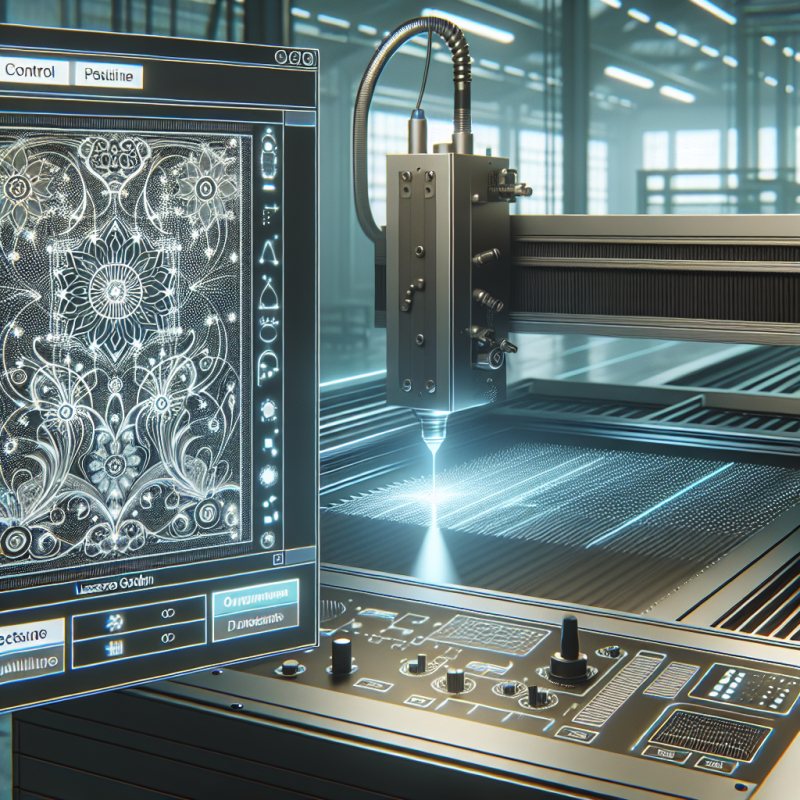

The process involves directing a focused laser beam at the material, which heats and vaporizes it to create precise cuts. Advanced software controls the laser’s path, allowing for intricate designs. Key components include:

- Laser Source: Generates the high-powered beam.

- Focusing Optics: Directs the laser precisely onto the material.

- Motion Control: Moves the laser or material for accurate cutting.

This technology is particularly beneficial for creating delicate, custom jewelry pieces with intricate details that would be challenging to achieve manually.

Applications in Jewelry Design

Jewelry laser cutters are versatile and find applications in:

- Custom Designs: Enabling unique, personalized jewelry creations.

- Repairs: Allowing precise adjustments to damaged pieces.

- Engraving: Adding detailed engravings and patterns.

- Prototyping: Quickly producing design samples for testing.

- Mass Production: Efficiently manufacturing identical pieces with high precision.

Challenges and Considerations

While beneficial, jewelry laser cutting presents challenges:

- Cost: High initial investment in equipment and setup.

- Learning Curve: Requires training to operate effectively.

- Material Limitations: Not suitable for all materials, especially reflective ones without proper settings.

- Maintenance: Regular upkeep is essential for optimal performance.

Selecting the Right Jewelry Laser Cutter

Choosing the right cutter involves evaluating:

- Type of Laser: CO2 or fiber lasers, each suited to different materials and applications.

- Power Output: Higher power suits thicker or harder materials but must be adjusted for delicate ones.

- Precision Requirements: Ensure the cutter meets your design needs, especially for intricate details.

- Build Quality and Software Compatibility: Look for durable equipment with compatible software for ease of use.

- Budget and Customer Support: Consider costs and availability of support for troubleshooting and maintenance.

Maintenance and Safety Tips

To maximize your cutter’s lifespan:

- Regularly clean the machine to prevent dust buildup, which can affect performance.

- Calibrate frequently to maintain precision and avoid misalignment issues.

- Ensure proper ventilation in the workspace to handle fumes from cutting materials.

Frequently Asked Questions

1. Can a jewelry laser cutter be used for all types of metals?

Not all, but many can with appropriate settings and precautions, especially non-ferrous metals like gold and silver.

2. Is it difficult to learn how to use one?

While training is needed, modern cutters come with intuitive software, making them accessible even for newcomers.

Conclusion

A jewelry laser cutter is a transformative tool for designers and manufacturers, offering precision, speed, and versatility. Despite challenges like initial costs and learning curves, its benefits make it a worthwhile investment. By understanding how to choose, use, and maintain this technology, you can elevate your jewelry designs to new heights.

Ready to explore the possibilities? Visit our site to learn more and find the perfect cutter for your needs!