Title: Transforming Leather Craft with Laser Technology

Introduction

In the realm of craftsmanship, particularly when working with leather, the fusion of precision and creativity is essential. The advancement of technology has brought forth the machine to cut leather, revolutionizing how artisans engage with their materials. These innovative machines serve as collaborative partners, enhancing both creativity and technical execution in leatherwork.

Understanding Laser Engraving Technology

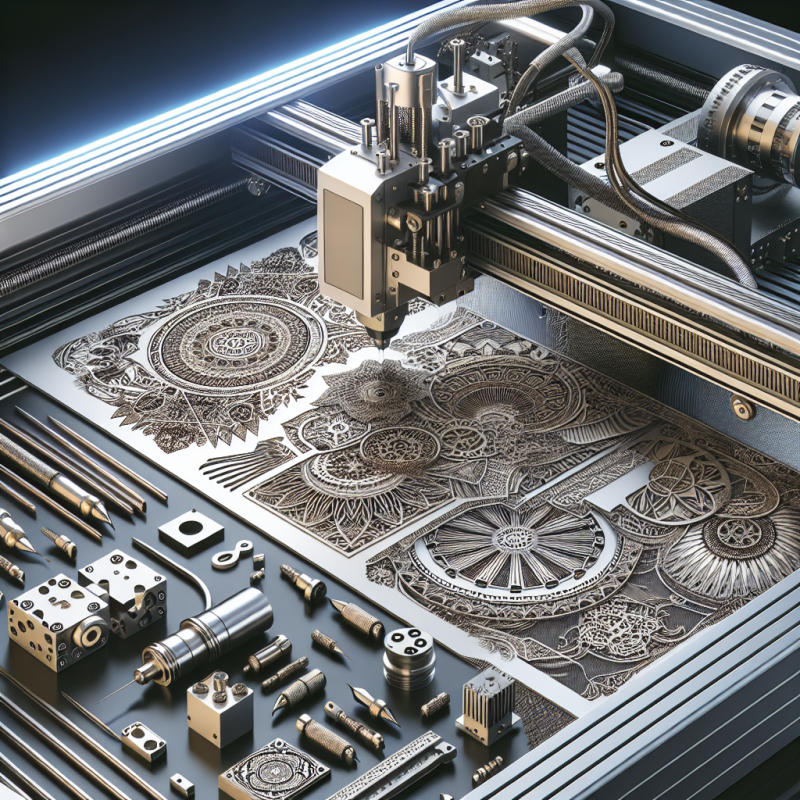

Laser engraving machines operate by utilizing highly concentrated beams of light to cut or etch various materials with remarkable precision. Their adaptability spans numerous applications, catering to hobbyists and large-scale industrial production alike. In the world of leatherworking, these machines enable the creation of intricate designs that would otherwise demand substantial manual labor. The machine to cut leather truly embodies this shift in craftsmanship, providing artisans with tools to produce stunning results efficiently.

Applications of Laser Engraving in Leather

Laser engraving machines fulfill a multitude of roles in the leather industry. From custom designs for leather handbags to intricate detailing on jackets, they allow artisans to execute complex ideas swiftly. Their precision makes them invaluable for individual craftsmen and larger manufacturing operations alike, making the machine to cut leather an optimal choice for diverse projects.

Key Specifications of Laser Machines

To fully harness the potential of a laser engraving machine, it is important to understand its specifications and features. For instance, the LaserPecker LP3 is designed for top-tier precision and boasts advanced functionalities. This model excels in fine engraving on various materials, which is especially advantageous for leather workers who seek efficiency coupled with detailed creative expression.

Key features of the LaserPecker LP3 include:

- High-precision laser technology for intricate cutting and engraving tasks.

- Compatibility with a variety of materials such as leather, metals, and plastics.

- An intuitive interface designed for user-friendly experiences.

- A compact design that optimizes workspace.

These features enhance the usability of the machine to cut leather, establishing it as a favored choice among creatives and industrial users alike.

Material Versatility

A prominent feature of the machine to cut leather is its capability to handle various materials. While leather is its primary focus, this machine can also cut and engrave other substances such as metal and plastic. This compatibility broadens the creative horizons for craftsmen, empowering them to experiment and innovate across multiple projects.

Can intricate designs be engraved on more challenging materials like metal? Absolutely—thanks to the LaserPecker LP3’s versatility, users can achieve superb results on different substrates without sacrificing precision or detail.

Safety Protocols for Laser Engraving

Safety is paramount when operating a laser engraving machine. Implementing appropriate safety measures protects users and maximizes the longevity of the equipment. Here are some essential safety practices:

- Always use protective eyewear to guard against laser exposure.

- Ensure a well-ventilated workspace to reduce harmful fumes produced during engraving.

- Place the laser machine on a stable surface to avoid accidents.

- Regularly inspect the equipment for wear or damage to prevent malfunctions.

By incorporating these precautions, users can focus on their craftsmanship while prioritizing safety.

Best Practices for Optimal Performance

To maximize the functionality and output quality of a machine to cut leather, adhering to industry best practices is essential. Knowing the specifications of the leather type and its thickness greatly impacts the final outcomes. Adjusting laser settings to align with the leather’s texture can enhance precision in both cutting and engraving significantly.

Why is this calibration important? Proper calibration ensures accurate cuts and engravings, minimizing waste while maximizing fidelity in design.

Evaluating Costs and Benefits

Investing in a laser engraving machine such as the LaserPecker LP3 requires a cost-benefit analysis. While the initial investment may appear substantial, the long-term advantages, including reduced manual labor, enhanced production speed, and decreased material waste, often outweigh the costs.

How does this investment compare to traditional leather cutting methods? Over time, the efficiency and precision provided by the machine to cut leather can surpass the operational costs associated with manual techniques, delivering both economic and creative benefits.

Maintenance and Care Tips

Regular maintenance of your laser engraving machine is crucial for ensuring its longevity and consistent performance. Preventative care not only preserves the machine’s aesthetics but also sustains its functionality over time. Key maintenance recommendations include:

- Keep the laser lens clean to guarantee optimal laser efficiency.

- Execute software updates as needed to benefit from the latest features and optimizations.

- Regularly inspect power sources and connections to prevent electrical issues.

- Lubricate moving parts as necessary to ensure smooth operation.

Adopting these maintenance practices can significantly extend the lifespan of your machine to cut leather while maintaining its high performance.

Creative Project Ideas with Laser Machines

The versatility of a laser engraving machine opens up a plethora of project possibilities. Whether you are a hobbyist or a seasoned professional, consider exploring creative ventures such as:

- Custom leather wallets and phone cases featuring unique engravings.

- Personalized belts with intricate designs.

- Decorative leather coasters and bookmarks.

- Artistic engravings on leather jackets.

How can tutorials enhance your skills with the machine? Engaging with online tutorials offers invaluable step-by-step guidance in operating the machine to cut leather, which helps users refine their techniques and uncover new possibilities in their craft.

Conclusion

In summary, integrating laser engraving technology into leather craftsmanship has unlocked a myriad of opportunities for artisans and businesses alike. The advanced capabilities provided by machines like the LaserPecker LP3 empower users to elevate their creative expressions with unmatched precision and efficiency. Whether you are an accomplished leatherworker or just starting out, the machine to cut leather will not only enhance your productivity but also enrich your artistry and creative potential.