Title: Transforming Metal Signage: The Ideal Machine for Precision Cutting

Introduction

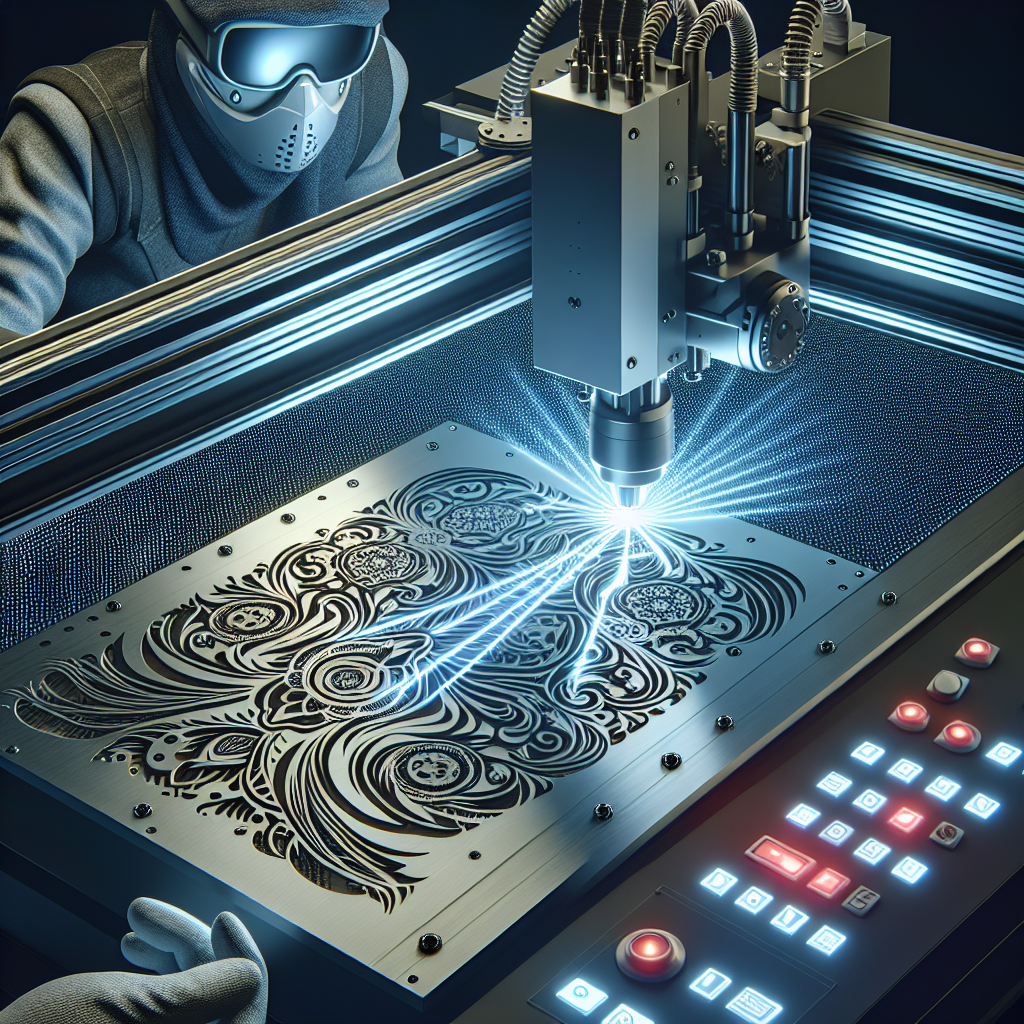

In the realm of modern craftsmanship, the ability to create intricate and precise designs is paramount. The advent of laser engraving technology has transformed how artists and manufacturers approach the creation of metal signs. A top-tier machine to cut metal signs not only enhances creativity but also boosts efficiency and cost-effectiveness in production. This article explores the remarkable capabilities and benefits of using laser engraving machines for this purpose.

Laser Engraving Technology and Applications

Laser engraving technology has revolutionized industries by providing precise cuts and intricate designs on various materials. It uses concentrated light beams to etch and cut through metals, offering unparalleled precision. This accuracy allows artisans and engineers to create highly detailed and durable metal signs that stand out. The technology’s versatility opens up numerous applications beyond just artistic endeavors, including industrial labeling, promotional signs, and personalized gifts.

Machine Specifications and Features

A top-notch machine to cut metal signs, such as the LaserPecker LP3, boasts impressive specifications that ensure exceptional performance. Key features include high-speed engraving capabilities, adjustable power settings, and compatibility with various design software. These machines are crafted for user-friendly operation, featuring intuitive interfaces that make them accessible even to non-expert users. Additionally, advanced cooling systems prevent overheating, ensuring prolonged usage without performance dips.

Material Compatibility

The LaserPecker LP3 is highly compatible with a diverse range of materials, including plastics, wood, and leather, in addition to metals. This flexibility allows creators to explore mixed-material designs, enabling unique projects. When selecting a machine to cut metal signs, considering its material versatility ensures that users can achieve the best results across various applications.

Safety Considerations

While operating a laser engraver, safety is of utmost importance. Ensuring that safety features such as emergency stop buttons, protective encasings, and laser shielding are in place can prevent accidents. Operators should always wear protective gear, including goggles that shield their eyes from laser exposure. Proper ventilation is essential to avoid inhalation of fumes released during cutting operations. Always verify that the machine has appropriate safety certifications to ensure regulatory compliance.

Industry Best Practices

To maximize the efficacy of your laser engraving machine, adhering to industry best practices is crucial. Regular calibration of the laser for optimal focus and alignment, as well as maintaining a clean workspace, are essential steps. Additionally, routinely checking and adjusting power settings based on the thickness and type of material can prolong the machine’s lifespan and maintain consistent performance quality.

Cost-Benefit Analysis

Investing in a high-quality machine to cut metal signs, like the LaserPecker LP3, can yield significant cost benefits. Though the initial investment may appear substantial, the long-term savings in labor, material wastage, and time make it a cost-effective choice. The ability to create prototypes and adjust designs in-house, without needing to outsource, translates to reduced expenses and greater control over the production process.

Maintenance Tips

Maintaining your laser engraver is crucial for ensuring its longevity and functionality. Regular cleaning of machine components, particularly the lenses and mirrors, is essential to prevent debris buildup that could obstruct the laser beam. Lubricating moving parts minimizes friction and wear. Moreover, following the manufacturer’s maintenance schedule for regular checks and part replacements helps ensure that your machine operates at peak performance, preventing unexpected breakdowns.

Project Ideas and Tutorials

With a reliable machine to cut metal signs, the range of potential projects is vast and exciting. Consider creating custom metal signage for local businesses, intricate metal art pieces for home decor, or personalized metal plaques for awards. For new users, numerous online tutorials and community forums offer essential guidance, including step-by-step instructions and design files to help kickstart your laser engraving journey.

Frequently Asked Questions

What is the best material for laser engraving metal signs?

The ideal material often depends on the intended use. Metals like stainless steel and aluminum tend to yield excellent results in terms of durability and clarity.

How do I choose the right machine to cut metal signs?

Focus on the machine’s power, its compatibility with design software, and the range of materials it supports. The LaserPecker LP3 is a versatile option for various projects.

Is it difficult to operate a laser engraving machine?

Modern machines are designed to be user-friendly, featuring intuitive interfaces that make them accessible even to beginners.

What software is commonly used with these machines?

Most laser engravers are compatible with popular design software such as AutoCAD, Adobe Illustrator, and other proprietary applications.

How can I ensure safety when using laser technology?

Investing in personal protective equipment, ensuring proper ventilation, and strictly adhering to the machine’s safety protocols can significantly minimize risks when operating laser technology.

Conclusion

In summary, a state-of-the-art machine to cut metal signs provides an excellent combination of precision, versatility, and speed. Whether for personal projects or professional manufacturing, these machines represent a sound investment for anyone serious about craftsmanship. Embracing these technological advancements allows creators to push the boundaries of what’s possible, forging new paths in artistic and industrial applications alike.