Title: How Much Does Laser Engraving Cost? Find Out Now

Understanding Laser Engraving Costs and Applications

Introduction

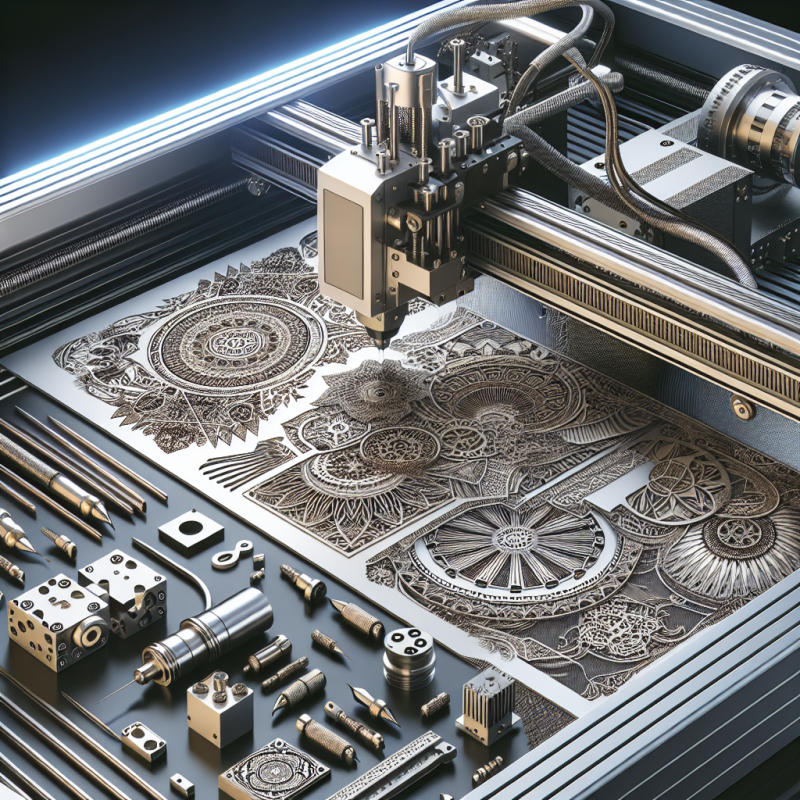

Laser engraving has emerged as a versatile and innovative technology with numerous applications across various industries. From creating intricate designs on wood to personalizing gadgets and crafting bespoke jewelry, the potential uses of a laser engraving machine are virtually limitless. Moreover, understanding how much does laser engraving cost is crucial for both hobbyists and professionals looking to invest in this technology. This article offers an exploration of laser engraving, focusing on technology, machine specifications, material compatibility, and associated costs while emphasizing industry best practices and safety considerations.

Laser Engraving Technology and Applications

Laser engraving technology utilizes a laser beam to create precise designs and patterns on various materials. The process is non-contact, meaning it does not physically interact with the material, reducing wear and tear. Laser engraving is extensively used in industries such as electronics, medical devices, automotive, and fashion, showcasing its versatility. Common applications include:

- Creating detailed art and designs on wood, glass, and acrylic.

- Marking electronics for identification and security purposes.

- Customizing jewelry, trophies, and awards for personalization.

- Engraving logos and labels on industrial products for branding.

Machine Specifications and Features

Before investing in a laser engraving machine, it’s vital to understand the key specifications and features that will impact your engraving projects. Several factors to consider include:

- Laser Power: Measured in watts, the laser power determines the machine’s ability to cut or engrave different materials. Higher power allows for deeper cuts and faster engraving speeds.

- Work Area: The size of the machine’s engraving area, which affects the types of projects that can be undertaken. Larger work areas allow for larger items or multiple engravings simultaneously.

- Resolution: Measured in dots per inch (DPI), higher resolution results in finer detail and better image quality.

- Speed: Typically measured in inches per second, speed can determine how quickly jobs are completed, affecting production efficiency.

- Software Compatibility: Ensures the machine can communicate effectively with design software, enabling precise control over the engraving process.

Material Compatibility

One of the significant advantages of laser engraving is its compatibility with a wide range of materials, including:

- Wood: Ideal for creating detailed carvings and burn marks for artistic applications.

- Acrylic: Perfect for producing distinct and sharp engravings, often used in signage and displays.

- Glass: Enables etching delicate patterns without the risk of breakage, used in decorative arts and gifts.

- Metals: Laser engravers can mark and cut certain metals, useful in industries such as automotive and electronics.

- Leather: Allows for intricate patterns and customization in fashion and accessories.

Understanding the specific capabilities of your machine with different materials is essential for achieving optimal results.

Safety Considerations

Operating a laser engraving machine requires strict adherence to safety protocols to prevent accidents and injuries. Important safety considerations include:

- Eye Protection: Always wear protective eyewear designed for use with lasers to prevent eye damage.

- Ventilation: Ensure proper ventilation in the work area to avoid inhaling smoke and fumes produced during engraving.

- Material Safety: Verify that the materials being engraved do not emit hazardous fumes when burned.

- Equipment Maintenance: Regularly maintain and clean the machine to avoid malfunctions that could lead to safety hazards.

Industry Best Practices

To maximize the efficiency and effectiveness of a laser engraving machine, it’s crucial to adhere to industry best practices. These include:

- Conducting routine maintenance checks to ensure all components are functioning correctly.

- Calibrating the machine regularly to maintain precision and accuracy.

- Keeping a log of conducted jobs and settings for consistency in repeatable tasks.

- Experimenting with different speeds and power settings to find the optimal balance for specific materials and designs.

Cost-Benefit Analysis

When considering how much does laser engraving cost, it’s important to conduct a cost-benefit analysis. While the initial investment for a laser engraving machine may be significant, the benefits often outweigh the costs due to increased productivity, precision, and versatility. Some key factors to evaluate include:

- The potential for increased creativity and product offerings.

- The ability to customize products, thus attracting a broader customer base.

- Reducing production time and labor costs through efficient automation.

- The durability and longevity of the machine, providing a prolonged return on investment.

Maintenance Tips

Proper maintenance of a laser engraving machine can enhance its performance and extend its lifespan. Important maintenance tips include:

- Regularly cleaning the lens and mirrors to ensure clear and precise laser paths.

- Lubricating moving parts to prevent wear and improve motion smoothness.

- Replacing worn components, such as belts and bearings, to avoid disruptions in operations.

- Inspecting the cooling system to prevent overheating, which can damage internal components.

Project Ideas and Tutorials

Engaging with laser engraving projects can stimulate creativity and demonstrate the machine’s capabilities. Here are some project ideas to get you started:

- Customized Gifts: Design unique gifts such as personalized photo frames or engraved jewelry.

- Home Décor: Craft decorative items like engraved glassware or wooden signs.

- Business Branding: Create branded merchandise like engraved keychains or custom business cards.

- Educational Projects: Design educational tools or models for classroom settings.

Tutorials and guided projects can provide detailed insights into specific engraving techniques and help users refine their skills.

Conclusion

Laser engraving technology presents numerous opportunities for businesses and individuals alike, with applications spanning various industries. Understanding how much does laser engraving cost involves evaluating machine specifications, material compatibility, and safety considerations. By adhering to industry best practices and embracing creative projects, users can unlock the full potential of their laser engraving machines.

Additionally, considering the financial implications while thinking about how much does laser engraving cost will empower users to make informed decisions that benefit their business or personal projects. Approaching the topic systematically allows individuals to assess how much does laser engraving cost with a clear perspective.

Embracing this technology offers immense potential for creativity and innovation across various fields. As you navigate the considerations of investing in laser engraving technology, remember that how much does laser engraving cost encompasses not just the initial purchase but also the benefits derived from improved efficiency and unique product offerings.

Engaging in laser engraving opens up a realm of possibilities, and understanding how much does laser engraving cost can help you leverage this technology to its fullest extent, enhancing both personal craft projects and professional business ventures. With this knowledge, potential customers and users can confidently explore the various dimensions of laser engraving and ensure they make the best choices suited to their needs.