Understanding Laser Engraving Prices: A Comprehensive Guide

Laser engraving has become a popular method for creating precise, durable, and visually appealing designs on various materials. Whether you’re working with metals, plastics, wood, or other surfaces, laser engraving offers unparalleled precision and efficiency. However, one of the most common questions people have is about laser engraving prices. What factors influence these costs? How can you ensure you’re getting a fair deal? This article will walk you through everything you need to know about laser engraving pricing and how to choose the right service for your needs.

Factors Affecting Laser Engraving Prices

The cost of laser engraving varies depending on several factors, including:

- The type of material being engraved

- The complexity and size of the design

- The number of items or projects

- The equipment used (industrial vs. desktop laser engravers)

- The expertise of the service provider

Let’s break down each factor to understand how they impact the laser engraving price.

Material Type: Different materials have varying levels of difficulty when it comes to laser engraving. For instance, metals like stainless steel or aluminum require more power and precise control compared to softer materials like wood or plastic. As a result, engraving on metal surfaces often costs more than engraving on wood.

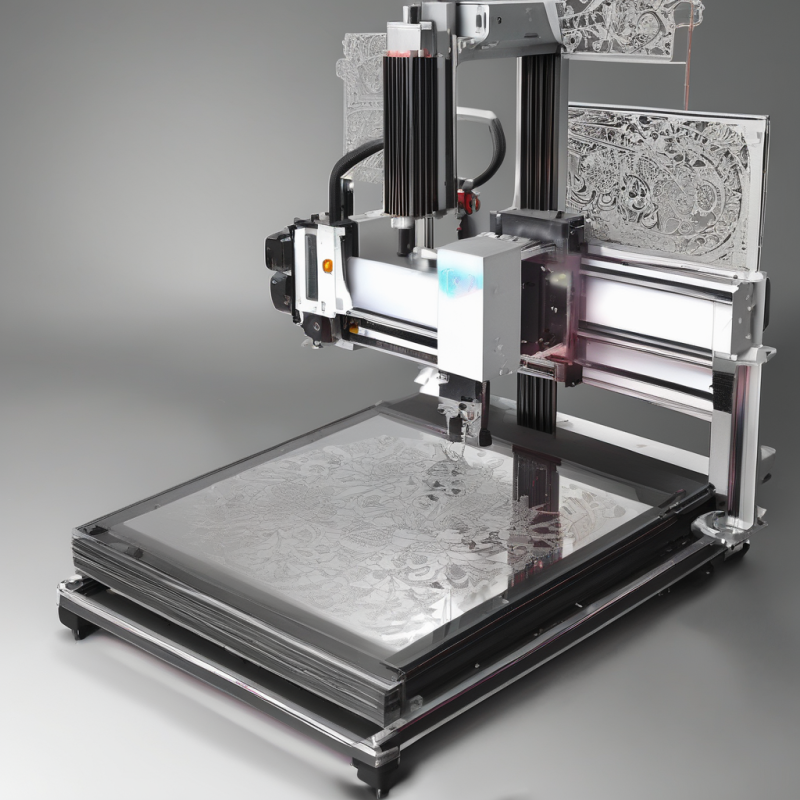

Complexity and Size: The complexity of the design plays a significant role in determining the price. Intricate designs with fine details take longer to execute and may require more adjustments, which can increase the overall cost. Similarly, larger designs or projects that cover extensive areas will naturally be more expensive than smaller, simpler ones.

Volume: If you’re engraving a large batch of items, you might qualify for bulk pricing discounts. On the other hand, single-piece projects or small batches typically cost more per unit due to setup and operational costs.

Industrial vs. Desktop Laser Engravers

Another critical factor influencing laser engraving prices is whether you’re using an industrial-grade laser cutter or a desktop machine. Industrial laser cutters, like the one offered at , are designed for high-volume, precision work. They can handle larger materials and more complex designs, making them ideal for businesses or professionals.

On the other hand, desktop laser engravers are compact and user-friendly, perfect for small-scale projects or hobbyists. While they’re more cost-effective upfront, their capabilities are limited compared to industrial machines.

Which one should you choose? If you’re running a business with consistent demand for laser engraving services, investing in an industrial-grade machine is likely the better option. However, if you’re just starting out or only need occasional engraving work, a desktop model might be sufficient.

Comparing Laser Engraving to Other Methods

Before deciding on laser engraving, it’s essential to compare it with other engraving methods in terms of cost and quality. Traditional engraving methods like mechanical or chemical etching are often more labor-intensive and less precise than laser engraving. While they might be cheaper upfront, the lack of precision and customization can lead to higher costs in the long run due to rework or unsatisfied clients.

Laser engraving stands out for its ability to produce high-quality, permanent marks with minimal setup time. It’s also highly customizable, allowing you to create intricate designs that would be difficult or impossible to achieve with traditional methods.

Applications of Laser Engraving

Understanding the applications of laser engraving can help you better assess its value and determine whether it’s worth the investment. Some common uses include:

- Customized Products: Engraving names, logos, or designs on jewelry, tools, firearms, or promotional items.

- Industrial Marking: Adding serial numbers, barcodes, or safety information to machinery and components.

- Fine Art: Creating detailed artistic engravings on wood, metal, or stone.

How does this affect pricing? The application often determines the complexity of the design and the materials used, both of which influence the laser engraving price. For example, custom firearm engraving requires high precision and attention to detail, making it a more costly service compared to simpler projects like logo engraving on metal signs.

Choosing the Right Laser Engraving Service

When selecting a laser engraving service, there are several considerations to keep in mind:

- Experience and Reputation: Look for a company with a proven track record of delivering high-quality work. Reading reviews or asking for references can help you gauge their reliability.

- Customization Options: Ensure they offer the design flexibility you need to bring your vision to life.

- Pricing Transparency: A trustworthy service provider should provide a clear, upfront estimate of costs based on your project’s requirements.

Why choose industrial laser engraving? Industrial-grade machines like the one mentioned earlier at offer superior precision, speed, and versatility, making them ideal for both small and large-scale projects.

Tips to Reduce Laser Engraving Costs

If you’re on a tight budget but still want high-quality results, here are some tips to minimize your expenses:

- Simplify Your Design: Avoid overly intricate patterns that require extensive time and effort.

- Opt for Bulk Orders: Many providers offer discounts for larger quantities, so consider combining multiple projects into a single order.

- Choose Less Expensive Materials: Select materials like wood or plastic if your project allows, as they are easier and cheaper to engrave than metals.

By making smart choices about your design, materials, and volume, you can enjoy the benefits of laser engraving without breaking the bank.

Frequently Asked Questions About Laser Engraving Prices

1. How much does laser engraving typically cost?

The cost varies widely depending on the factors discussed earlier. On average, you can expect to pay between $50 and $300 per project, though this can go higher for complex or large-scale work.

2. Can I get a discount for bulk orders?

Yes! Many laser engraving services offer volume discounts, especially for businesses with recurring projects. Be sure to ask about their pricing structure when inquiring about your project.

3. Is laser engraving more expensive than other methods?

While the upfront cost of laser engraving can be higher than traditional methods, it often proves more economical in the long run due to its precision and durability. It also allows for greater creativity and customization, which can add value to your products or projects.

Conclusion

Understanding laser engraving prices is essential for making informed decisions about your project. By evaluating factors like material type, design complexity, and equipment quality, you can better estimate the costs involved and choose a service that meets both your budget and quality expectations. Remember, investing in an industrial-grade laser cutter, such as the one available at this affordable option, can provide long-term savings and superior results for your engraving needs.

Ready to get started? Contact a trusted laser engraving service today to discuss your project and receive a personalized quote.