Understanding Laser Engraving Pricing: A Comprehensive Guide

Introduction

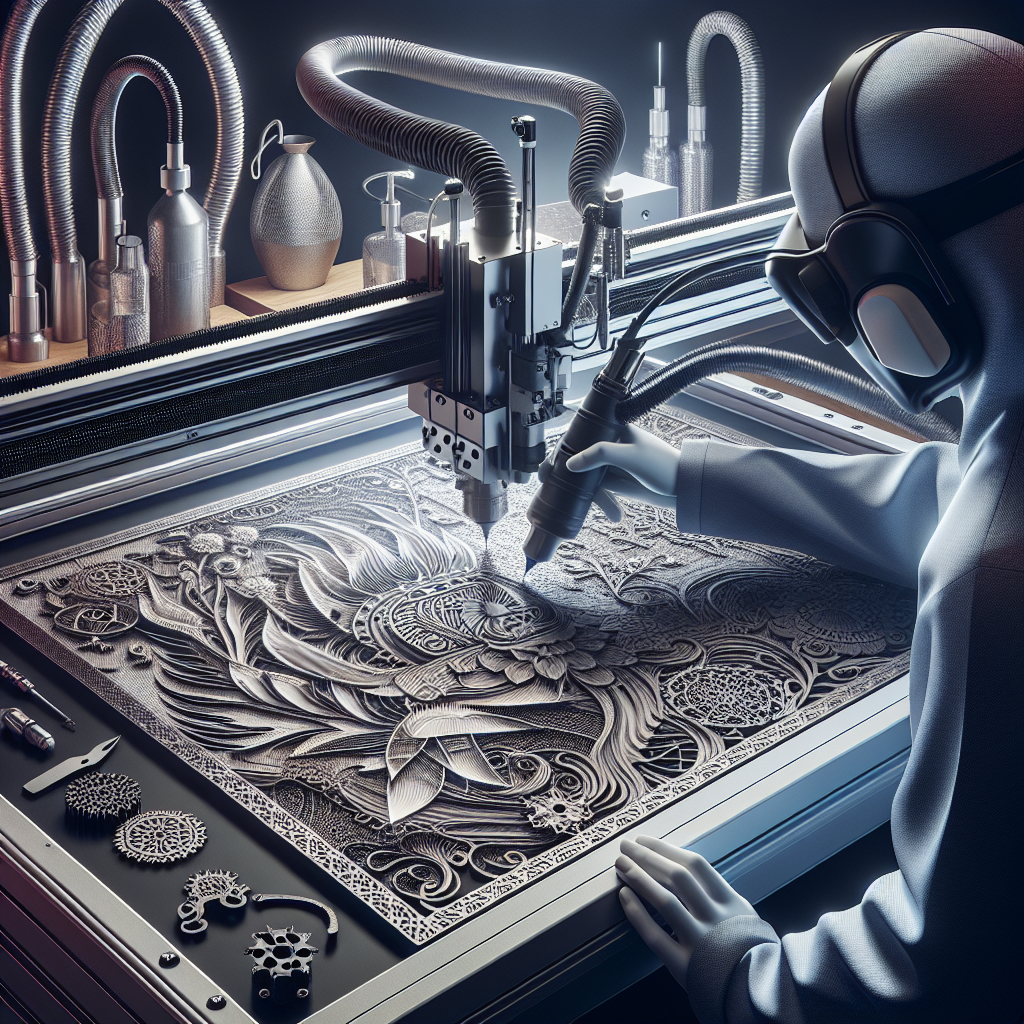

Laser engraving is a pivotal technology that allows for precise and high-quality personalization and marking across numerous industries. With the growing demand, understanding laser engraving pricing is essential for both businesses and hobbyists. This article dissects the intricacies of laser engraving machines, detailing their applications, material compatibility, and the transformative potential they hold for various projects.

Laser Engraving Technology and Applications

Laser engraving utilizes concentrated laser beams to etch designs onto surfaces, offering considerable flexibility for creating intricate patterns and texts across diverse materials. Its applications range from personalizing gifts and jewelry to industrial-grade markings, underscoring the importance of understanding laser engraving pricing for effective budget planning.

Machine Specifications and Features

Key specifications are pivotal in determining laser engraving pricing. Important features include:

- Power Output: Higher wattage enables deeper engravings and speedy processing.

- Engraving Area: Defines the maximum dimensions of materials that can be engraved.

- Speed and Precision: Vital for production efficiency and quality of engravings.

- Software Compatibility: Advanced software can enhance design manipulation and usability.

These features impact both performance and laser engraving pricing, guiding informed purchasing decisions.

Material Compatibility

One appealing aspect of laser engraving is its compatibility with a broad range of materials, assisting in managing laser engraving pricing and optimizing material use. Common materials include:

- Wood: Known for crafts and personalized items; lends a rustic charm.

- Leather: Offers sophistication and durability, suitable for personalized apparel and accessories.

- Metal: Ideal for industrial applications demanding durability and precision.

- Glass and Acrylic: Create elegant designs ideal for awards and signage.

Unique settings for each material affect laser engraving pricing due to different costs and processing necessities.

Safety Considerations

Strict adherence to safety protocols is mandatory when operating laser engraving machines to prevent accidents and extend equipment life. Essential safety practices include:

- Ensure proper ventilation to dispel fumes.

- Wear protective eyewear to safeguard against laser emissions.

- Regularly inspect and maintain laser alignment and focus.

Proper safety measures protect the operator and avert unforeseen expenses, thereby affecting laser engraving pricing.

Industry Best Practices

Adopting industry best practices is crucial for quality and efficiency in laser engraving. Precision is key to successful engraving, and regular machine calibration alongside surface preparation enhances results, justifying the laser engraving pricing.

Cost-Benefit Analysis

Conducting a cost-benefit analysis is essential to understanding laser engraving pricing. Material consumption rates, power usage, labor, and production timelines all influence overall costs.

The benefits, such as increased customization options, rapid production rates, and enhanced precision, often justify the initial investment and ongoing expenses of operating a laser engraving machine.

Maintenance Tips

Regular maintenance is critical for the longevity and efficiency of laser engraving machines. Maintenance tips include:

- Clean the laser lens and mirrors routinely to sustain optimal beam quality.

- Inspect belts and motors for wear to avert breakdowns.

- Keep the machine’s software regularly updated to exploit new features and improvements.

Proactive maintenance ensures consistent quality, minimizes downtime, and optimizes laser engraving pricing over time.

Project Ideas and Tutorials

The versatility of laser engraving offers endless creative opportunities. Consider these project ideas:

- Personalized leather notebooks

- Customized wooden signage

- Intricate metal jewelry engravings

- Etched glass awards and trophies

Exploring various projects not only highlights the value of laser engraving but also provides insights into optimizing laser engraving pricing across different applications.

Conclusion

Understanding laser engraving pricing involves assessing machine features, material compatibility, and operational benefits. By evaluating these factors in conjunction with maintenance practices and creative applications, both individuals and businesses can make informed investment decisions, ultimately enhancing their projects and increasing operational efficiency.