Mastering the LaserPecker LP2: Your Ply Cutting Machine

Introduction

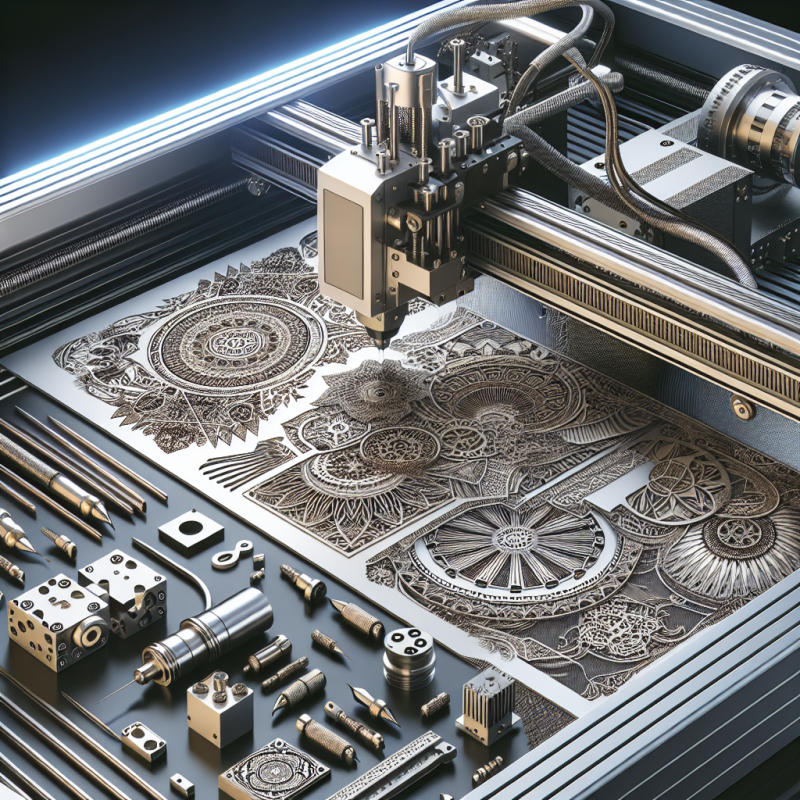

In the dynamic world of manufacturing and art, laser engraving technology stands at the forefront of precision and creativity. For those looking to make detailed and intricate designs, a ply cutting machine such as the LaserPecker LP2 offers an invaluable tool. This article delves into the multifaceted uses, specifications, safety considerations, and maintenance of laser engraving machines, with a specific focus on the LaserPecker LP2.

Laser Engraving Technology and Applications

Laser engraving technology utilizes focused light, allowing users to inscribe or cut designs smoothly onto a variety of materials. This method surpasses traditional techniques in speed, accuracy, and versatility. The ply cutting machine like LaserPecker LP2 particularly shines in applications ranging from creating personalized gifts to intricate industrial components.

Artists and craftsmen benefit immensely as the machine simplifies the work, enabling them to focus on innovation while ensuring each piece achieves a professional finish. Such technology is also increasingly employed in educational settings, providing students a hands-on experience with cutting-edge engineering.

Machine Specifications and Features

The LaserPecker LP2 is not just any laser engraver; it’s a ply cutting machine designed with portability and ease of use in mind. Key features include:

- Portable Design: Its compact, handheld design means you can take your creativity anywhere, making it ideal for both studio and fieldwork.

- High Precision: With a carefully calibrated laser, it allows for minute details and fine lines, which is crucial for complex designs.

- Multiple Modes: Adjustable settings cater to both engraving and cutting, offering versatility across projects.

- Smart Interface: The user-friendly app enables effortless customization and control. Simply upload designs, adjust settings, and let the machine do the work.

Material Compatibility

The versatility of a ply cutting machine like the LaserPecker LP2 is evident in its ability to work across numerous materials. This machine can engrave and cut on:

- Wood

- Leather

- Glass

- Plastic

- Fabric

- Paper and Cardboard

These options make it suitable for a broad range of projects, from fashion design to personalized home decor. However, it’s important to note that the material’s thickness and composition can affect the outcome, so adjustments to settings may be necessary for optimal results.

Safety Considerations

Safety is paramount when operating any laser machine. Before starting, users should ensure they understand and adhere to safety protocols. Here are some vital points to consider:

- Protective Gear: Always wear protective eyewear to prevent eye damage from laser exposure.

- Ventilation: Operate the machine in a well-ventilated area to avoid inhaling fumes, particularly when cutting plastic or other synthetic materials.

- Material Flammability: Be aware of the flammability of materials, as the heat generated by lasers can be a fire hazard.

- Child Safety: Keep the machine out of reach of children and educate any younger operators on the importance of safety procedures.

Industry Best Practices

For those new to using a ply cutting machine, understanding industry best practices can significantly impact the quality and efficiency of projects. Consider the following tips:

- Test Runs: Always start with a test piece of the same material to calibrate settings.

- Plan Your Design: Thoroughly prepare and preview designs digitally before engraving to catch any potential errors.

- Regular Maintenance: Keep the machine clean and perform regular maintenance checks to ensure optimal performance.

- Software Updates: Regularly update machine software to benefit from the latest features and security improvements.

Cost-Benefit Analysis

Investing in a ply cutting machine like the LaserPecker LP2 can initially seem substantial, but the long-term benefits often outweigh the costs. Consider the advantages:

- Precision and Quality: Achieving the fine details that manual methods often fail to deliver.

- Increased Productivity: Faster turnaround times on projects can directly translate into profitability.

- Material Efficiency: Minimal waste occurs with precision cuts, saving money on materials.

- Creative Freedom: With customization capabilities, you can offer clients unique, tailor-made products.

Maintenance Tips

Regular maintenance is key to prolonging the life of your ply cutting machine. Here are essential tips to follow:

- Dust and Debris: Frequently clear away dust and debris from the laser head and bed.

- Alignment Checks: Regularly check and correct the alignment to ensure the laser cuts accurately.

- Lubrication: Lubricate moving parts as per the manufacturer’s guidelines.

- Component Replacement: Replace worn parts promptly to avoid strain on other components.

- Firmware Updates: Keep the machine’s firmware updated to maintain compatibility with software and hardware developments.

Project Ideas and Tutorials

Getting the most from a ply cutting machine involves exploring a wide variety of projects. Here are some ideas to spark your creativity:

- Customized Gifts: Personalize items such as phone cases, coasters, or jewelry with unique engravings.

- Home Decor: Craft intricate wall art or decorative panels.

- Industrial Prototyping: Rapidly prototype components for manufacturing.

- Educational Tools: Create engaging learning aids tailored to specific educational topics.

- Fashion and Textiles: Experiment with laser-cut patterns on fabrics for bespoke clothing.

Consider joining online forums and attending workshops to exchange ideas and enhance your skills. Many communities provide tutorials that cater to both beginners and seasoned professionals.

Conclusion

The LaserPecker LP2 proves to be more than just a ply cutting machine; it’s a gateway to endless possibilities in art, design, and manufacture. By understanding its technology, application, and best practices, users can harness its full potential safely and effectively. Whether for personal enjoyment or professional endeavors, laser engraving and cutting empower you to bring your visions to life with unmatched precision.