3D Laser Printer Engraver: Revolutionizing Laser Engraving Technology

Introduction

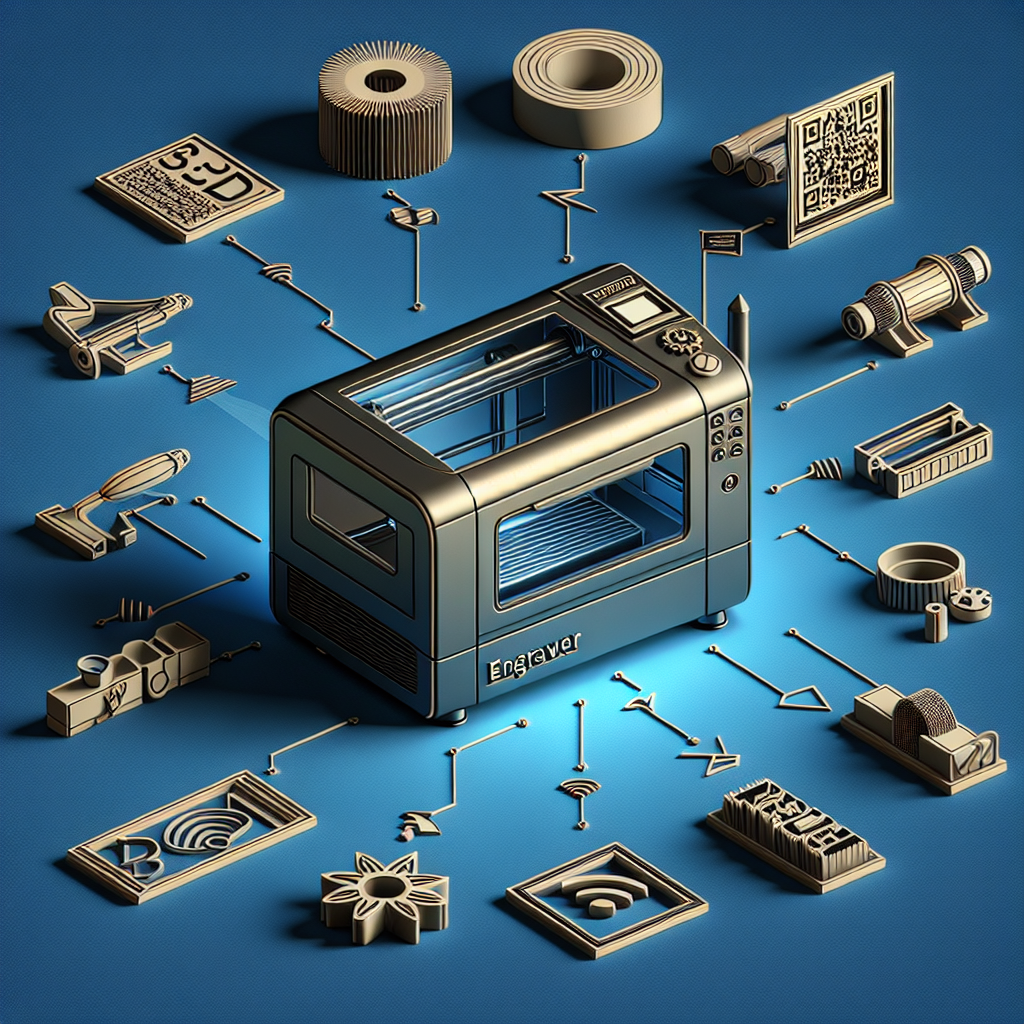

The advent of 3D laser printer engraver technology has significantly transformed the landscape of laser engraving. This innovative technology offers unparalleled precision, versatility, and efficiency, making it an indispensable tool in various industries. Whether you’re a hobbyist, small business owner, or a professional in the manufacturing sector, understanding the intricacies of 3D laser printer engravers can provide immense benefits. This article delves into the technology, its applications, machine specifications, material compatibility, safety considerations, industry best practices, cost-benefit analysis, maintenance tips, and exciting project ideas.

Laser Engraving Technology and Applications

Laser engraving involves using a high-intensity laser beam to create intricate designs, text, or images on various materials. This process is non-contact, meaning there is no physical interaction between the laser and the material, reducing the risk of damage. The 3D laser printer engraver takes this technology a step further by enabling three-dimensional engraving, which opens up a world of possibilities.

Applications of 3D laser printer engravers are vast and diverse. They are commonly used in:

- Jewelry Design: Creating intricate patterns and personalizations on metal jewelry pieces.

- Industrial Prototyping: Making precise models and prototypes for product development.

- Personalization: Engraving names, dates, and logos on gifts, awards, and memorabilia.

- Art and Craft: Producing detailed works of art on wood, glass, and other materials.

- Aerospace: Marking components for traceability and identification.

- Medical Devices: Etching serial numbers and other critical information on surgical instruments.

Machine Specifications and Features

When choosing a 3D laser printer engraver, it’s crucial to consider its specifications and features to ensure it meets your needs. Key specifications include:

- Laser Power: Measured in watts (W), higher power lasers can cut thicker materials and engrave faster.

- Workspace Dimensions: Determines the maximum size of the object you can work on.

- Resolution: Indicates the finest detail the laser can produce, measured in dots per inch (DPI).

- Software Compatibility: Ensures seamless integration with your design software.

- Material Handling: Includes the types of materials the machine can process and any required accessories or adaptations.

Modern 3D laser printer engravers come with advanced features such as:

- Automatic Focus Adjustment: Ensures consistent engraving depth across different materials.

- Closed-Loop Stepper Motors: Provide high precision and repeatability.

- Air Assist: Blows air onto the workpiece to prevent charring and improve cut quality.

- Rotary Attachments: Allow for engraving cylindrical objects.

- Wi-Fi Connectivity: Enables remote control and monitoring.

Material Compatibility

One of the most appealing aspects of 3D laser printer engravers is their versatility in processing a wide range of materials. Common materials include:

- Metals: Stainless steel, titanium, and aluminum can be marked or etched with a fiber laser.

- Woods: Various woods, from softwoods like pine to hardwoods like oak, can be beautifully engraved.

- Plastics: Acrylic, polycarbonate, and PVC can be cut and engraved with precision.

- Glass: Using special techniques, intricate patterns can be etched onto glass surfaces.

- Leather: Ideal for personalizing bags, belts, and other leather goods.

- Paper and Cardboard: Suitable for creating intricate pop-up cards and other paper crafts.

Safety Considerations

Working with 3D laser printer engravers involves handling high-energy laser beams, which can be hazardous if not managed correctly. Safety considerations include:

- Eye Protection: Always wear laser-safe glasses when operating the machine.

- Ventilation: Ensure adequate ventilation to prevent the accumulation of laser-generated fumes.

- Fire Precautions: Keep a fire extinguisher handy and have a clear escape route.

- Training: All operators should be thoroughly trained in machine operation and safety protocols.

- Emergency Stop: Familiarize yourself with the emergency stop button and its location.

Industry Best Practices

Adopting industry best practices can enhance the efficiency and longevity of your 3D laser printer engraver. Here are some key practices:

- Regular Maintenance: Schedule routine checks and maintenance tasks to prevent downtime.

- Material Preparation: Ensure materials are clean, dry, and properly clamped to avoid movement.

- Software Optimization: Use software features to optimize laser settings for different materials and thicknesses.

- Quality Control: Implement quality control measures to ensure consistent output.

- Documentation: Maintain detailed records of machine settings, material specifications, and project outcomes for future reference.

Cost-Benefit Analysis

Investing in a 3D laser printer engraver can be a significant financial commitment. However, a cost-benefit analysis often reveals substantial long-term benefits. On the cost side, consider:

- Initial Purchase Price: Includes the machine, accessories, and software.

- Operational Costs: Electricity, consumables, and maintenance.

- Training Expenses: Cost of training operators.

On the benefit side, consider:

- Increased Efficiency: Faster processing times and reduced labor costs.

- Versatility: Ability to process a wide range of materials and applications.

- Precision: High-quality output that enhances product value.

- Scalability: Potential to expand operations and increase capacity.

Maintenance Tips

Proper maintenance is crucial for keeping your 3D laser printer engraver in top condition. Here are some essential tips:

- Clean the Lens: Regularly clean the laser lens to remove dust and debris.

- Lubricate Moving Parts: Use appropriate lubricants to keep moving parts operating smoothly.