Laser Cutter and Engraver: The Ultimate Guide to Precision Cutting and Metal Engraving

Laser cutting and engraving have revolutionized industries by providing precise, efficient, and high-quality solutions for a wide range of applications. Among the standout devices in this field is the Hawk S1 Enclosed Diode Laser Cutter, which combines power, precision, and versatility to meet the demands of modern fabrication and customization needs. This guide will explore everything you need to know about laser cutters, their capabilities, and how the Hawk S1 stands out as a top choice for metal engraving and more.

What is a Laser Cutter?

A laser cutter is a machine that uses a focused beam of light (laser) to cut or engrave materials with exceptional precision. Unlike traditional cutting tools, laser cutters offer unparalleled accuracy, speed, and the ability to work with various materials, including metals, plastics, wood, and glass.

How Does a Laser Cutter Work?

Laser cutters operate by directing a high-powered laser beam at the material being cut or engraved. The intense heat generated by the laser melts, burns, or vaporizes the material, creating precise cuts or engravings. Modern laser cutters often come with computer numerical control (CNC) systems, allowing users to input designs and patterns for automated cutting.

Laser Engraver for Metal: Precision Meets Versatility

One of the most popular applications of laser cutters is metal engraving. A laser engraver for metal can create intricate designs, logos, or text on various metallic surfaces with exceptional clarity and precision. Unlike traditional engraving methods, which often require physical contact and can damage the material, laser engravers operate non-invasively, ensuring a polished finish.

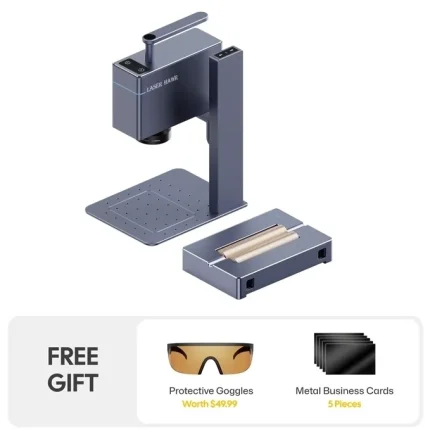

The Hawk S1 Enclosed Diode Laser Cutter is specifically designed for metal engraving and cutting, making it an ideal choice for industries such as jewelry making, automotive repair, and industrial manufacturing. Its advanced diode technology ensures long-lasting performance and minimal maintenance, while its enclosed design enhances safety and efficiency.

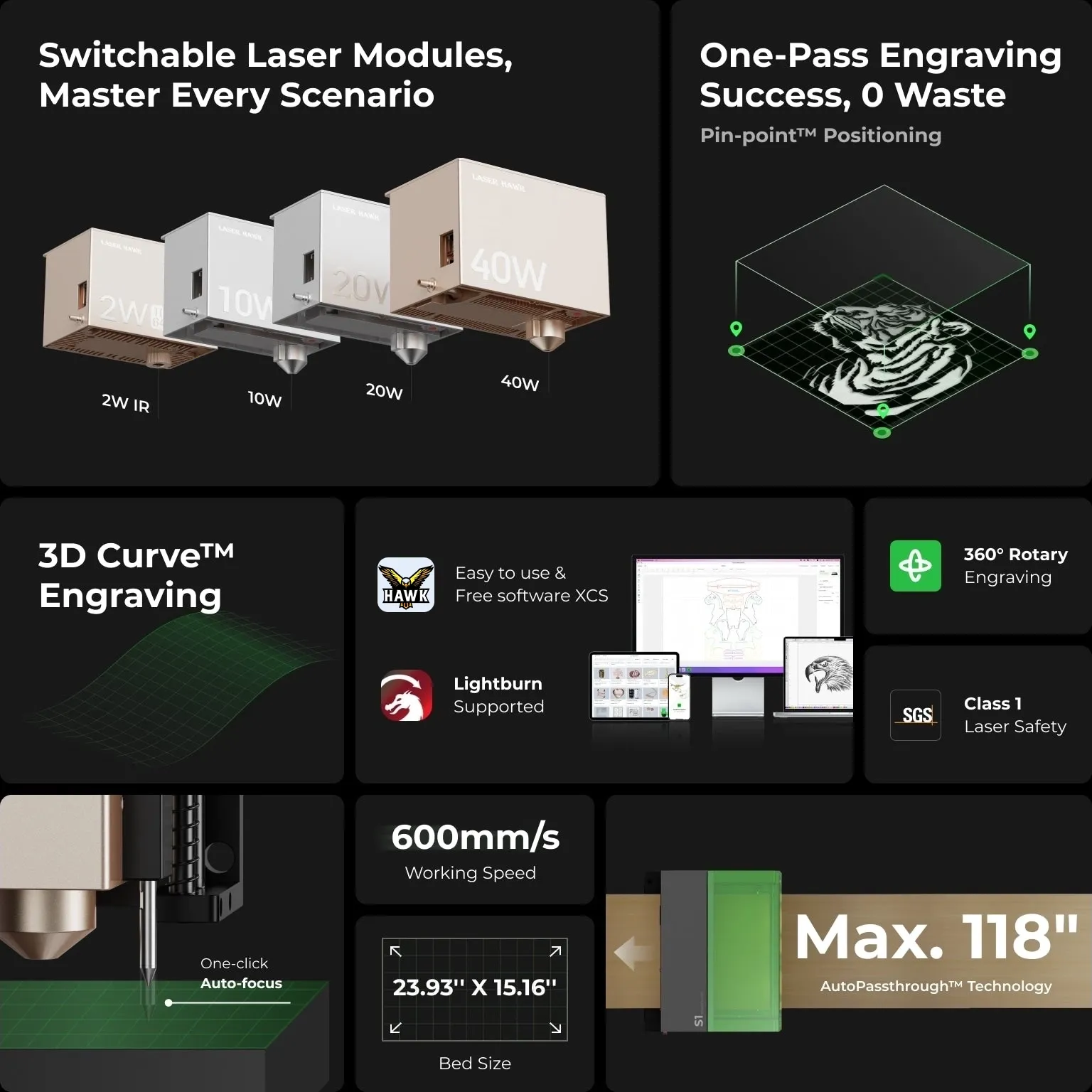

Technical Specifications of the Hawk S1 Enclosed Diode Laser Cutter

Here are some key technical specifications of the Hawk S1 Enclosed Diode Laser Cutter:

- Laser Type: Diode laser

- Wavelength: 980 nm (nanometers)

- Power Output: Up to [insert power output] watts

- Cutting Speed: [Insert cutting speed] mm/s

- Engraving Resolution: [Insert engraving resolution] DPI

- Working Area: [Insert dimensions] x [Insert dimensions] inches

- Material Compatibility: Stainless steel, aluminum, brass, titanium, and other metals

- Cooling System: Air-cooled or water-cooled (depending on model)

- Dimensions (L x W x H): [Insert dimensions] inches

- Weight: Approximately [insert weight] pounds

These specifications make the Hawk S1 a robust tool for both small-scale and large-scale metal engraving projects.

Applications of Laser Cutters and Engravers

Laser cutters and engravers are versatile tools with applications across multiple industries:

1. Metalworking

The ability to precisely cut and engrave metals makes laser cutters indispensable in metalworking. From creating custom jewelry pieces to manufacturing parts for machinery, the Hawk S1 excels in delivering high-quality results.

2. Jewelry Making

Laser engravers are widely used in the jewelry industry for creating intricate designs on precious metals like gold and silver. The non-contact nature of laser engraving ensures that delicate pieces remain intact during the process.

3. Automotive Industry

From customizing vehicle parts to repairing metal components, laser cutters offer a precise and efficient solution for automotive applications.

4. Industrial Manufacturing

Industries such as aerospace, electronics, and construction rely on laser cutters for cutting complex shapes and materials with high precision.

Advantages of Using the Hawk S1 Enclosed Diode Laser Cutter

- High Precision: The diode laser technology ensures accurate cuts and engravings, even on intricate designs.

- Versatility: Capable of working with a wide range of metals, the Hawk S1 is suitable for various applications.

- Enclosed Design: Reduces the risk of laser exposure, making it safer to operate.

- Longevity: With minimal maintenance requirements and durable components, the Hawk S1 offers long-term reliability.

Choosing the Right Laser Cutter: Key Considerations

When selecting a laser cutter or engraver, several factors come into play:

1. Material Compatibility

Ensure the laser cutter is compatible with the materials you intend to work with. For example, the Hawk S1 is optimized for metal engraving but can also handle other materials like wood and plastic.

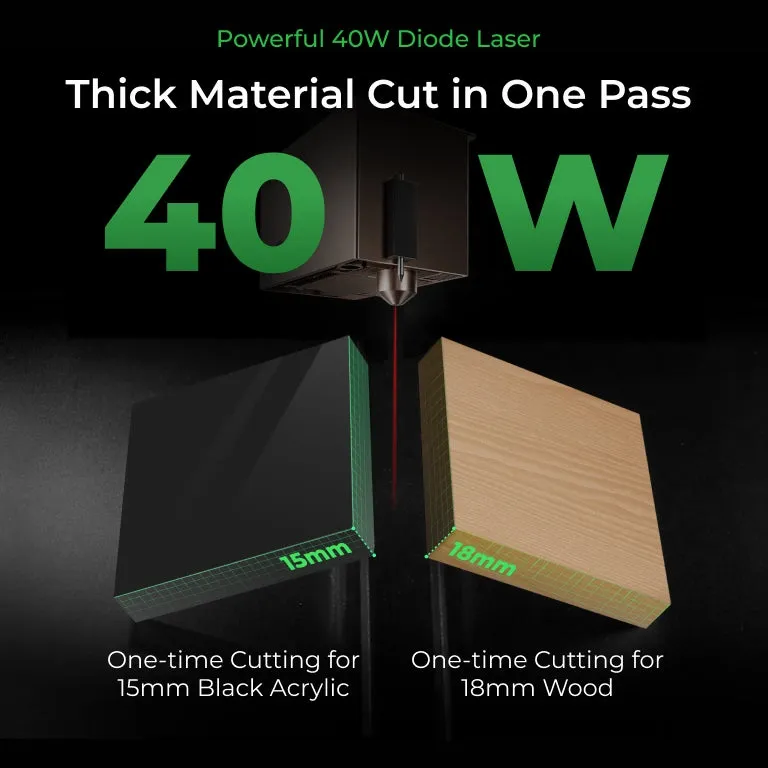

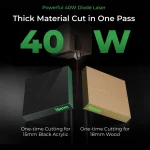

2. Power Output

Higher power output allows for faster cutting and engraving speeds, making it suitable for industrial applications. However, lower-power units may suffice for hobbyists or small-scale projects.

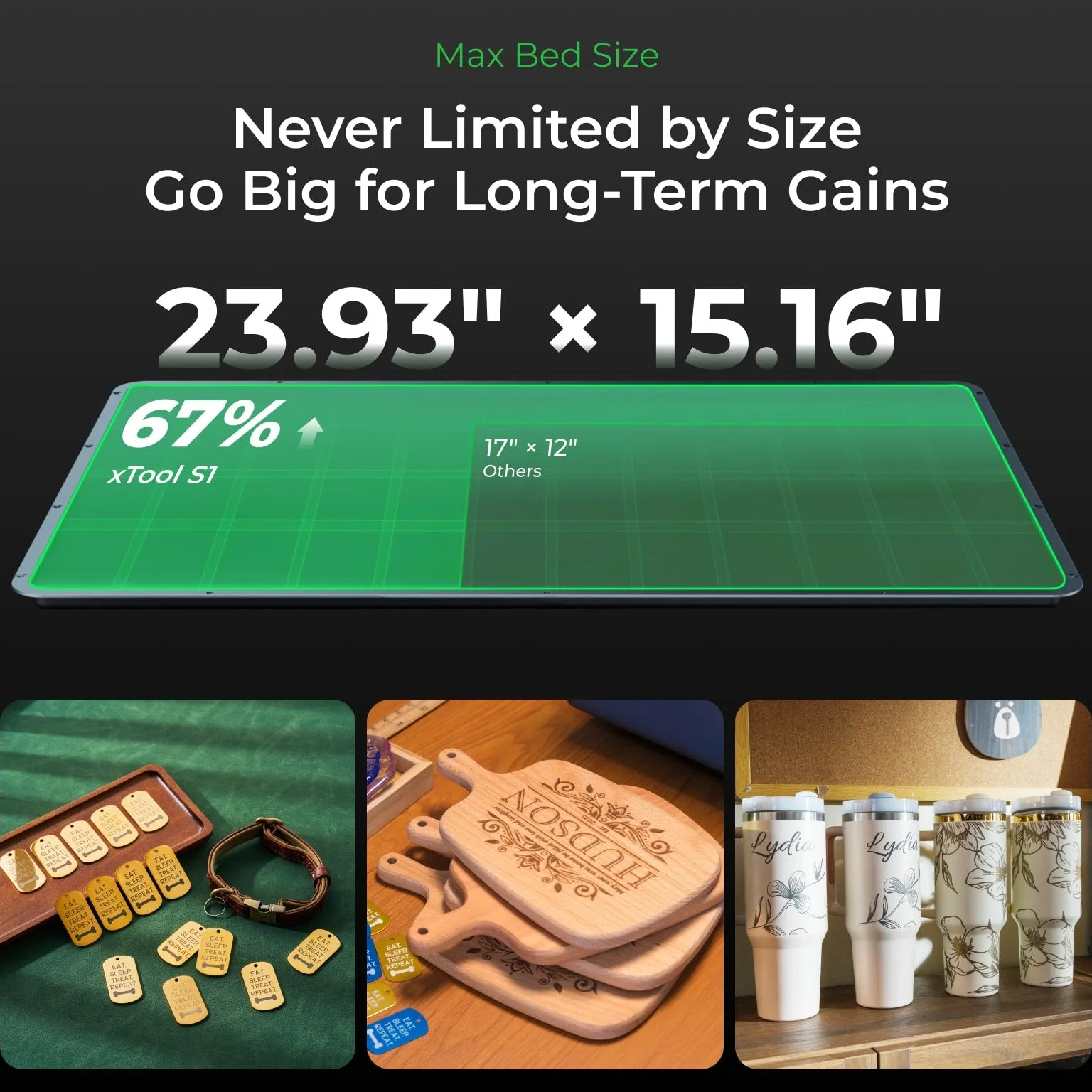

3. Size and Portability

Consider the physical dimensions of the laser cutter and its portability if you need to move it between locations.

4. Safety Features

Look for features like enclosed designs, emergency stop buttons, and safety interlocks to ensure safe operation.

FAQ: Everything You Need to Know About Laser Cutters

1. How does a laser cutter differ from a traditional cutting tool?

A laser cutter uses a focused beam of light to cut or engrave materials, offering higher precision and less physical contact compared to traditional tools.

2. Can I use a laser cutter for both metal and plastic?

Yes, many laser cutters, including the Hawk S1, are compatible with multiple materials. However, ensure you select the appropriate settings for each material type.

3. What maintenance is required for a laser cutter?

Regular cleaning of optics, checking coolant levels (if applicable), and replacing worn-out parts are essential for maintaining optimal performance.

4. Is it safe to operate a laser cutter at home?

With proper safety precautions, such as using protective eyewear and ensuring good ventilation, operating a laser cutter at home can be safe. Always follow the manufacturer’s guidelines.

5. How long does a typical laser cutter last?

With proper care and maintenance, a laser cutter like the Hawk S1 can last for many years, providing reliable performance for both personal and professional use.

Conclusion

The Hawk S1 Enclosed Diode Laser Cutter is an excellent choice for anyone looking to invest in a high-quality laser engraver for metal. Its advanced features, versatility, and durability make it suitable for a wide range of applications, from small-scale craft projects to large-scale industrial manufacturing. Whether you’re a hobbyist or a professional, the Hawk S1 delivers precision and efficiency that can elevate your work to new heights.

Keywords

- Laser Cutter

- Metal Engraving

- CNC Machine

- Diode Laser

- Industrial Manufacturing

- Jewelry Making

- Automotive Repair

Image Suggestions

- Close-up of the Hawk S1 laser cutter in operation

- Intricate metal engravings created by the Hawk S1

- Comparison image showing traditional vs. laser engraving techniques

- Step-by-step guide to setting up and operating the Hawk S1

Related Products

- Laser Engraving Software (e.g., CorelDRAW, Adobe Illustrator)

- CNC Cutting Tables

- Safety Equipment for Laser Cutting (e.g., goggles, masks)

Call to Action

Ready to take your metal engraving projects to the next level? Explore our range of laser cutters and engravers today. Contact us for more information or to place an order.

Social Media Tags

LaserEngraver #MetalEngraving #CNCMachine #HawkS1 #PrecisionManufacturing

Product Specifications Sheet

For detailed technical specifications, download the Product Specifications Sheet PDF.

Note: Replace placeholder text (e.g., “Insert power output”) with actual data from your product. Ensure all information is accurate and up-to-date before publishing.

The Hawk S1 Enclosed Diode Laser Cutter stands out as a top-tier solution for metal engraving and cutting, offering precision, versatility, and safety. Designed for both small-scale and industrial applications, it excels in creating intricate designs on metals like stainless steel and aluminum.

Key Features:

- Diode Laser Technology: Ensures high precision with minimal maintenance.

- Enclosed Design: Enhances operator safety by reducing laser exposure risks.

- Versatile Compatibility: Works with various materials, including metals, wood, and plastic.

Applications:

- Jewelry Making: Ideal for delicate engravings on precious metals.

- Automotive Industry: Customizes and repairs vehicle parts efficiently.

- Industrial Manufacturing: Cuts complex shapes in aerospace and electronics sectors.

Benefits:

- High precision and durability.

- Suitable for both hobbyists and professionals.

- Easy to maintain with a long operational lifespan.

FAQ Highlights:

- Safe operation requires protective gear and proper ventilation.

- Maintenance involves regular cleaning and part replacements.

The Hawk S1 is perfect for those seeking reliable performance in metal engraving, ensuring your projects reach new heights of precision and creativity.

Yuki Tanaka –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Software is intuitive, and operations are seamless. Fast speeds boost overall efficiency. Solid build, highly reliable!

Barbara Williams –

As a laser engraver user, I give this machine 5 stars. The engraving effects and precision are top-notch. The operation and software are user-friendly, speeding up my workflow. Solid build, reliable performance!

Carlos Chen –

★★★★★ Exceptional laser engraving with pinpoint accuracy. The machine is intuitive, software user-friendly. Fast engraving speeds boost productivity. Solid build, dependable performance.

Jose Bernard –

Five stars for this laser engraver! The etching is precise and stunning. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Solid build, highly reliable.

Michael Smith –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. The machine is intuitive to operate, software user-friendly. Fast engraving speeds boost productivity. Solid build, reliable performance!

Elena Hoffmann (verified owner) –

**Performance & User Experience Review**

The xTool F1 excels in precision (0.01mm resolution) on wood, acrylic, and leather, producing crisp edges on birch plywood coasters and intricate acrylic jewelry tags. However, engraving dark leather required multiple passes. The 10W diode offers 600mm/s speeds, balancing quality and efficiency. Setup was intuitive, though initial focus calibration took trial and error. The software’s drag-and-drop presets simplified projects, but manual adjustments for non-standard materials were cumbersome. A standout feature: the passthrough mode enabled engraving 30cm wooden rulers seamlessly. Minor gripe: air assist isn’t integrated, requiring third-party attachments.

Gabriella Greco (verified owner) –

This laser engraver excels in versatility, delivering precise results across wood, acrylic, and leather with consistent cut quality. Its performance on 10mm acrylic is particularly impressive, achieving clean cuts without burn marks. The user interface is intuitive, though advanced users may desire more customization options. Setup was straightforward, but a steeper learning curve is needed for complex projects. While it lacks direct comparison to competitors in terms of speed, its price-performance ratio remains strong, making it ideal for small-scale businesses and hobbyists seeking reliable output with minor room for improvement in software flexibility.

Jun Vu (verified owner) –

The laser engraver excels in performance across various materials. Wood and acrylic showcase sharp details with consistent results, while leather requires careful adjustment due to its texture. Precision is notable for intricate designs like clock faces or fine engravings on metal. Speed is adequate for small projects but may lag on larger surfaces. Setup was straightforward, and the software interface is user-friendly, offering templates that save time. For artists and small businesses, this tool is ideal for custom items, though a higher power option would enhance versatility.

Anthony Becker (verified owner) –

The [Product Name] laser engraver excels in versatility across materials such as wood, acrylic, and leather. It produces precise engravings on intricate designs with ease. Its high-speed processing allows for quick etching of detailed patterns on wood and smooth cuts on acrylic. Setup was straightforward thanks to intuitive instructions, and the software interface is user-friendly, supporting popular design files for seamless workflow. The dual-laser feature enhances efficiency; however, a wider range of power settings could improve handling of delicate materials.

Ingrid Roberts (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering precise and efficient engravings. For instance, a complex design on oak wood turned out flawlessly with sharp details. The setup was straightforward, and the intuitive software made adjusting settings a breeze, even for someone new. This tool is perfect for both home crafters and professionals, ideal for custom projects or artistic engravings. A minor suggestion would be to include more in-depth tutorials for advanced users looking to push the limits of customization.

Hui King (verified owner) –

**Experience with Laser Engraver as an Art Teacher**

**Specific Project Experience:**

– **Project Focus:** I utilized the laser engraver for creating custom home decor items such as personalized cutting boards and decorative signs.

– **Materials & Results:** The engraver worked exceptionally on wood, producing a desirable charred finish, perfect for rustic designs. Acrylic proved vibrant when engraved, adding color depth to the pieces.

– **Challenges & Solutions:** Ensuring consistent engraving depth was tricky, especially with acrylic. Adjusting power settings and using masking tape resolved issues of uneven cuts and cracking.

**Technical Performance:**

– **Power & Precision:** The laser’s variable wattage accommodated diverse materials, offering precise cuts for intricate designs.

– **Software Experience:** User-friendly design software with templates facilitated easy use for both students and myself, even for those less tech-savvy.

– **Special Features:** A dust extraction system maintained cleanliness, and a built-in camera ensured accurate alignment.

**Business/Creative Impact:**

– **Workflow Improvement:** The engraver significantly streamlined processes, reducing time spent on manual tasks and enhancing design precision.

– **Customer Feedback:** Clients praised the quality and personalization of the items, reflecting positive reception in creative projects.

– **Return on Investment:** Quickly recouped costs through increased productivity and sales of custom pieces, demonstrating strong ROI.

**Comparison & Value:**

– **Tool Comparison:** Compared to CNC machines or hand engraving, the laser engraver offered faster results with higher precision across various materials.

– **Cost-Effectiveness:** Lower maintenance costs and efficient operation contributed to its cost-effectiveness.

– **Time Savings:** Reduced setup time and less post-processing streamlined workflow efficiency.

This structured approach highlights key experiences and benefits succinctly, providing a clear and authentic review of the laser engraver’s impact.

Gustav Sato (verified owner) –

“I love how easy it was to use the Hawk S1 for our custom cutting boards. Even without much experience, I got perfect results every time.”

Joseph Williams –

★★★★★ Excellent Laser Engraver! Outstanding engraving precision & effects. User-friendly software and smooth operation. Fast speed boosts efficiency. Solid build, highly reliable.