Title: Advancements in Laser Engraving Technology

Introduction

In today’s rapidly evolving technological landscape, the laser engraver engraving machine stands out as a versatile tool with a myriad of applications. Whether for personal projects, small businesses, or industrial use, these machines have revolutionized how intricate designs and engravings are crafted on various materials.

Understanding Laser Engraving Technology

Laser engraving technology involves using high-energy laser beams to etch patterns, designs, or text onto the surface of a material. This technology is distinguished by its precision and the ability to produce consistent results with minimal material waste. The laser engraver engraving machine can adjust the depth and intensity of engravings, allowing for highly detailed and custom designs suitable for a variety of projects.

Applications of Laser Engraving

The applications for laser engraving are vast and diverse. This technology is widely used in industries such as jewelry design, personalized gifts, signage, and manufacturing for parts identification. As businesses and hobbyists recognize the value of personalization, the demand for advanced laser engravers continues to grow. Furthermore, home improvement projects often utilize the laser engraver engraving machine to add custom touches to interior decor.

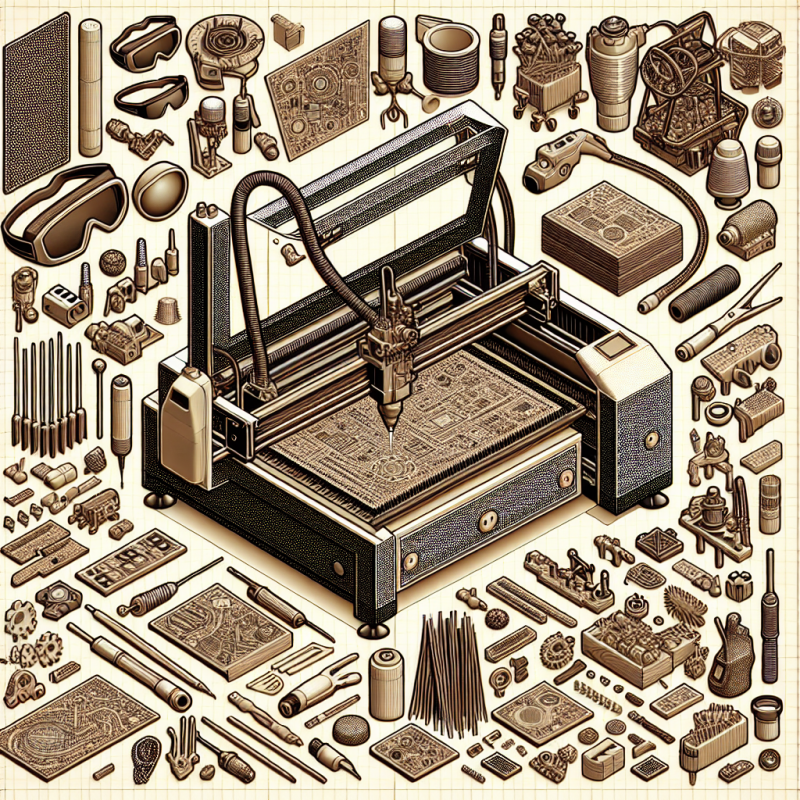

Machine Specifications and Features

Selecting the right laser engraver engraving machine involves understanding its specifications and features. Key considerations include:

- Laser Power: Determines the machine’s ability to engrave on various materials, impacting speed and detail.

- Engraving Area: The size of the workspace is crucial for accommodating different project dimensions.

- Cutting Speed: Higher speeds can enhance efficiency but may affect the level of detail achieved.

- Interface: A user-friendly interface is essential for ease of operation, especially for beginners.

Understanding these features can help potential users maximize the capabilities of their laser engraver engraving machine and ensure they meet specific project requirements.

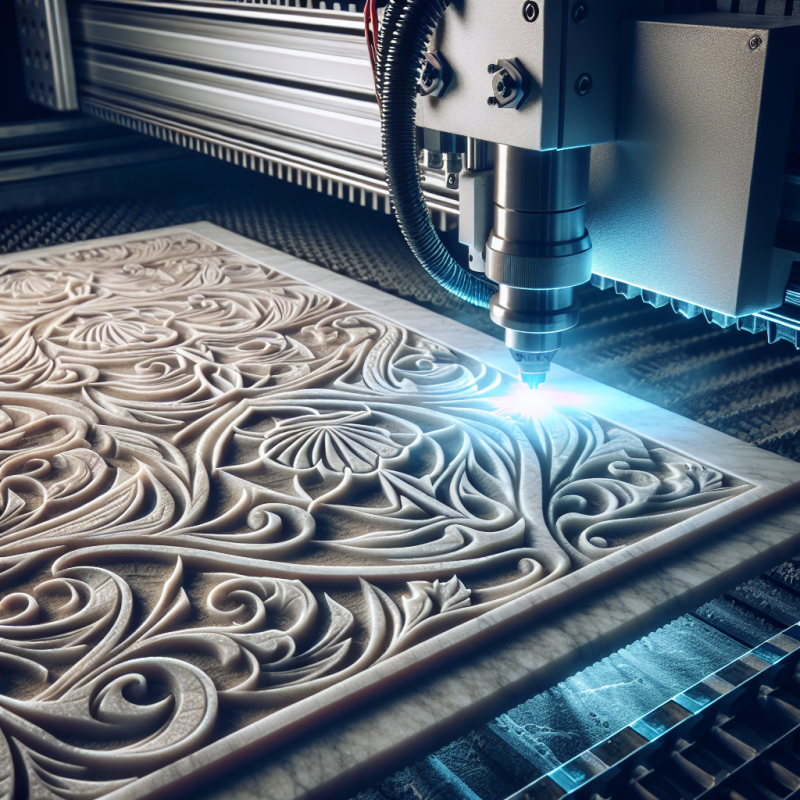

Material Compatibility

One remarkable aspect of the laser engraver engraving machine is its adaptability to a wide range of materials. From wood and acrylic to metals and leather, the machine can effectively engrave onto various substrates. However, it is essential to recognize the limitations with certain materials that may not respond well to laser engraving, thus affecting the outcome of projects.

Safety Considerations

Operating laser engraving machines requires strict adherence to safety protocols. Proper ventilation is crucial to avoid harmful fumes, the use of protective eyewear is mandatory, and regular maintenance helps ensure a safe engraving environment. Safety is paramount when working with high-energy lasers, and users should always prioritize their well-being along with that of their surroundings.

Industry Best Practices

Achieving the best results with a laser engraver engraving machine requires adherence to industry best practices. These include:

- Regularly calibrating the machine to maintain accuracy and consistency.

- Conducting tests on sample materials before proceeding to larger projects to ensure quality.

- Properly configuring software settings for different types of materials to optimize performance.

By following these guidelines, users can ensure consistent quality and efficiency in their engraving projects, leading to better overall results.

Cost-Benefit Analysis

Investing in a laser engraver engraving machine involves weighing both initial costs and potential long-term benefits. While the upfront price can be significant, the capabilities for customization, precision, and versatility can lead to increased revenue opportunities and improved customer satisfaction. It’s essential to consider these factors when contemplating a purchase, as the investment can pay off in various ways over time.

Maintenance Tips

To ensure the longevity of your laser engraver engraving machine, regular maintenance is vital. Essential maintenance tasks include:

- Cleaning the laser lens regularly to maintain clarity and precision in your engravings.

- Checking mechanical components for wear and tear to avoid unexpected downtimes.

- Updating software to ensure you benefit from the latest features and performance improvements.

Routine maintenance not only enhances performance but also protects your investment over time.

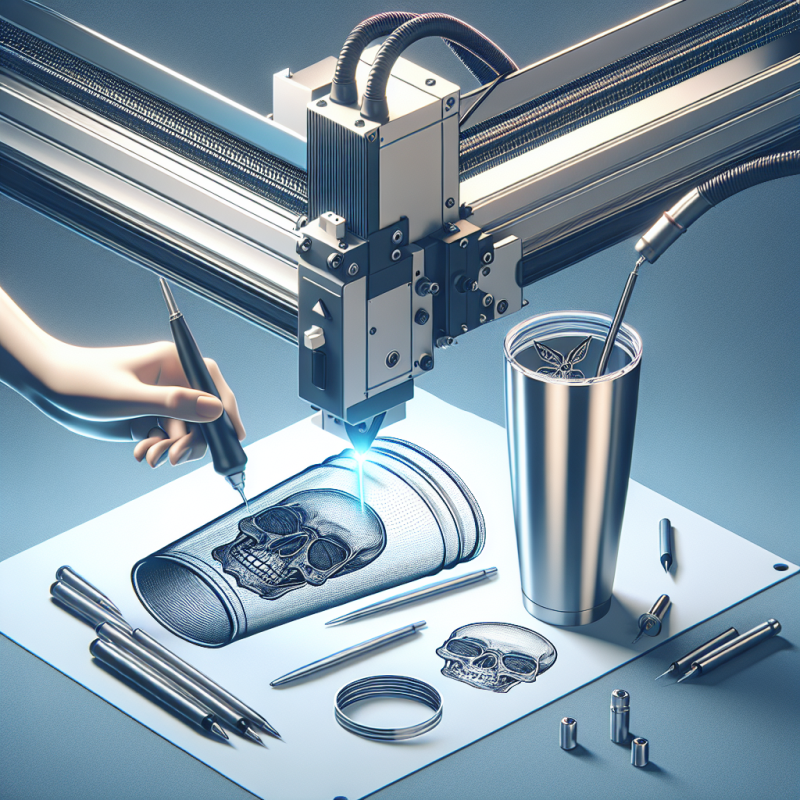

Project Ideas and Tutorials

The creative potential of a laser engraver engraving machine is immense, opening the door to numerous project possibilities. Here are some exciting ideas to explore:

- Customized drinkware featuring engraved quotes or logos, perfect for personal use or as gifts.

- Decorative wall art using layered acrylic or wood, allowing for unique interior decor options.

- Personalized keychains or coasters tailored for special events or as promotional items.

Numerous online tutorials can assist both novices and professionals in honing their skills and expanding their creative repertoire, enabling them to fully utilize their laser engraver engraving machine.

Frequently Asked Questions

As interest in laser engraver engraving machines grows, prospective users often have common questions:

- What materials can be engraved? Most non-reflective materials, including wood, plastics, and certain metals, can be effectively engraved.

- How long does it take to engrave a design? The duration depends on the complexity of the design and the speed settings of the machine.

- Is laser engraving safe? Yes, laser engraving is safe when proper safety measures, such as protective eyewear and adequate ventilation, are implemented.

Having an informed understanding of the machine can help users confidently tackle new projects and achieve desired results.

Conclusion

The capabilities of a laser engraver engraving machine are unparalleled, transforming creative concepts into tangible works of art. By understanding its technology, effectively using its features, and adhering to industry best practices, users can unlock the full potential of their investment. This ensures successful and safe engraving projects for years to come, solidifying the role of laser engraving technology in the creative industry.