The Future of Craftsmanship: Exploring the Art of Laser Engraving Machines

Introduction

In today’s rapidly evolving technological landscape, the laser engraver machine has emerged as a vital tool for both hobbyists and professionals. Its precision and versatility have significantly enhanced the capabilities of craftsmen, artists, and industrial designers alike. This article delves deep into the intricacies of laser engraving technology, exploring its myriad applications, machine specifications, and essential considerations for effective and safe usage.

Understanding Laser Engraving Technology

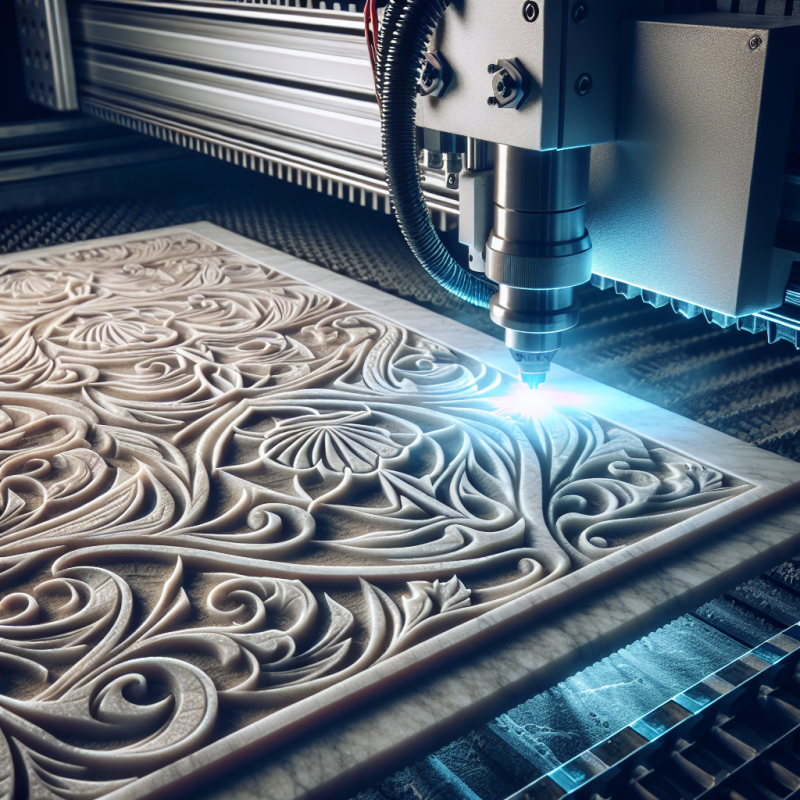

The laser engraver machine operates by focusing a high-powered laser beam to precisely remove material from the surface of an object, creating designs with incredible detail. The technology is lauded for its precision, efficiency, and ability to produce high-quality engravings swiftly. But what makes laser engraving superior to traditional methods?

Laser engraving offers unparalleled accuracy, making it ideal for intricate designs that require consistency. Unlike conventional engraving processes, it is a non-contact method, minimizing wear and tear on the workpiece. This ensures that the integrity of the material is maintained, resulting in long-lasting and durable finishes.

Versatile Applications of Laser Engraving

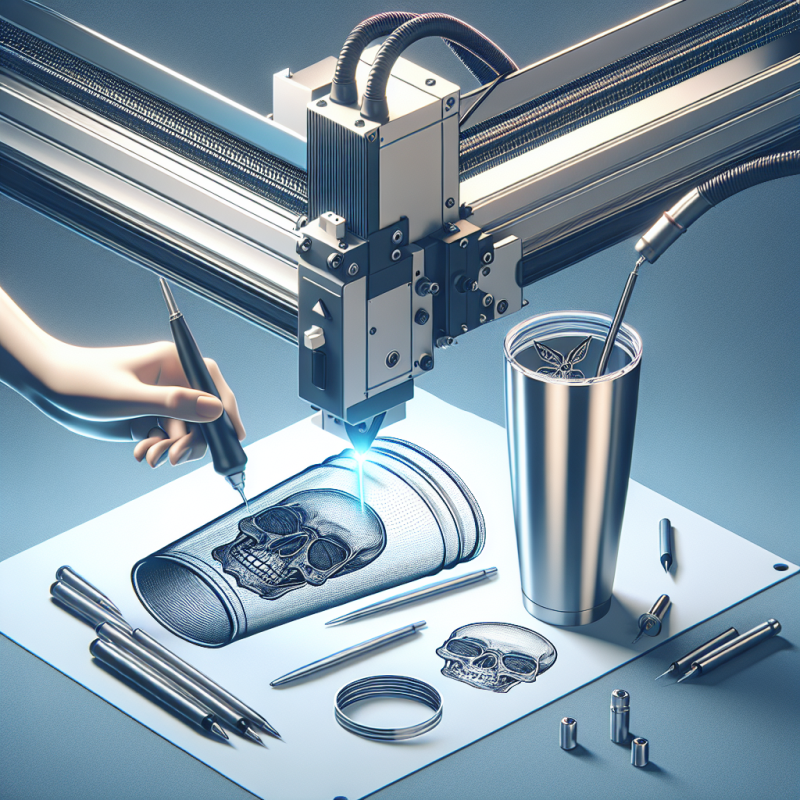

With the ever-growing adoption of laser engraver machines, numerous industries are benefiting from this technology. Whether it’s branding through customized logos, crafting personalized gifts, or designing architectural models, the applications are limitless.

- Jewelry Making: Laser engraving provides precision that captures every detail in fine jewelry, allowing for exquisite customizations.

- Industrial Manufacturing: Companies use laser engravers to etch serial numbers and barcodes onto products for tracking and identification.

- Medical Devices: With stringent standards in place, laser engraving ensures accurate and safe markings on surgical instruments and implants.

- Artwork and Design: Artists can explore new dimensions of creativity, crafting complex patterns and images that would be impossible by hand.

Machine Specifications and Features

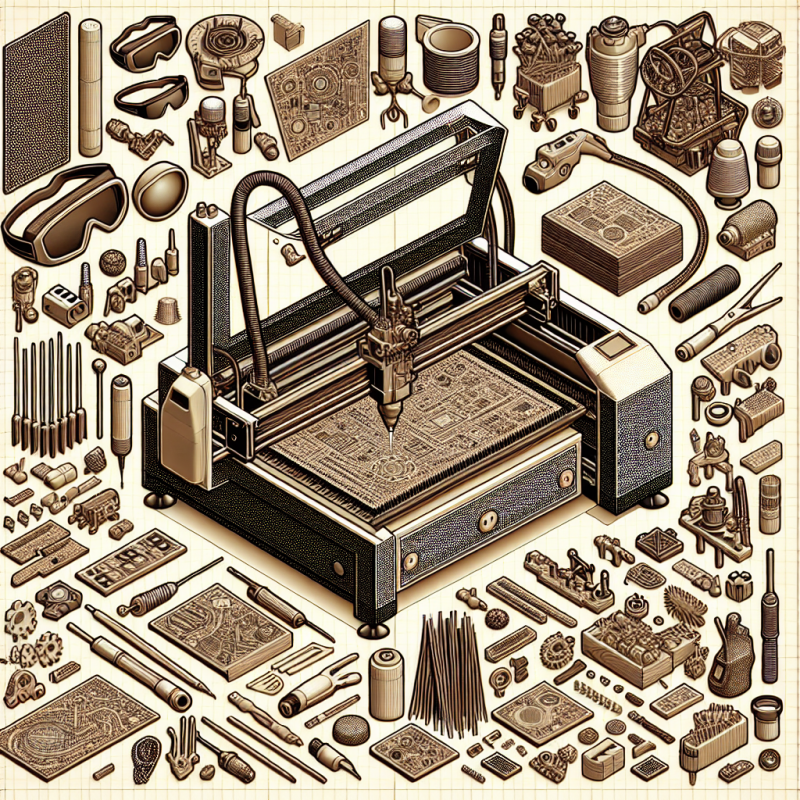

The capabilities of a laser engraver machine depend significantly on its specifications. Key features to look for include power output, maximum engraving area, and compatibility with different materials. Higher power outputs increase the variety and thickness of materials that can be engraved, while a larger engraving area allows for bigger projects.

Modern machines often include software compatibility that supports various design formats, providing users with greater flexibility. Advanced features such as auto-focus and speed control enhance usability, allowing for precise control over the engraving process.

Material Compatibility

A significant advantage of laser engraver machines is their ability to work with a wide range of materials. From wood and acrylic to metal and glass, the list is extensive. However, understanding the specifics of each material is crucial for achieving the desired results.

For instance, wood engravers often prefer softer woods like pine which respond well to laser cutting. Metals may require higher-powered lasers, and special caution is needed with materials like PVC, which can release harmful fumes when engraved.

Safety Considerations

Although laser engraver machines are efficient, they must be operated with strict adherence to safety protocols. It’s essential to wear protective equipment and work in a well-ventilated area to avoid exposure to harmful fumes. Regular maintenance of the laser system is vital to ensure it remains in optimal working condition.

What safety measures should operators keep in mind? Among others, never operate the machine unattended and ensure the correct calibration to avoid uncontrolled laser dispersion. Safety features such as emergency stops and protective covers should also be considered when choosing a machine.

Industry Best Practices

For professionals, following industry best practices ensures optimal performance and longevity of the laser engraver machine. Regular cleaning of the machine to prevent residue buildup is vital, and storing materials in suitable conditions reduces the risk of damage.

Using high-quality materials and keeping software updated are simple yet effective strategies to achieve better engraving results. Additionally, training for operators on new technologies and techniques can lead to more efficient workflows.

Cost-Benefit Analysis

While investing in a laser engraver machine may have a high initial cost, the long-term benefits outweigh the investment. The machine enables faster production times and reduces labor costs, making businesses more competitive.

Moreover, the ability to offer customized products can open new revenue streams. When analyzing costs, it’s important to consider not only the purchase price but also ongoing maintenance and potential upgrades.

Maintenance Tips

Maintenance is critical to keeping a laser engraver machine functioning efficiently. Regularly inspecting the optical components for dirt and cleaning them safely can prevent engraving errors. Periodically checking all movable parts for wear and ensuring proper lubrication can extend the machine’s lifespan.

Periodic software updates should not be neglected as they often include performance improvements and bug fixes. Creating a maintenance schedule and adhering to it is a best practice that can save costly repairs in the future.

Project Ideas and Tutorials

For those looking to maximize the laser engraver machine‘s potential, exploring various projects can be both exciting and financially rewarding. Consider creating custom home decor or personalized gifts. The possibilities are endless, from intricate cut-out greeting cards to engraved coasters and photo albums.

Tutorials can guide users on setting up basic designs and progressively tackling more challenging projects. They broaden one’s understanding of the machine capabilities and encourage experimentation, which is crucial in unveiling the engraver’s full potential.

In conclusion, the laser engraver machine is a versatile tool that has transformed creative industries. By understanding its technologies, applications, and best practices, users can fully harness its power. Whether as a hobby or a professional endeavor, laser engraving opens a gateway to innovation and artistic expression.