Title: Exploring Laser Engraving Machines

Introduction

The laser engraver engraving machine has revolutionized the realm of customization, providing exceptional precision and versatility. These machines are extensively utilized across various industries, from manufacturing to small home businesses. Understanding the significance of laser engravers is essential for anyone considering this remarkable technology.

Laser Engraving Technology and Applications

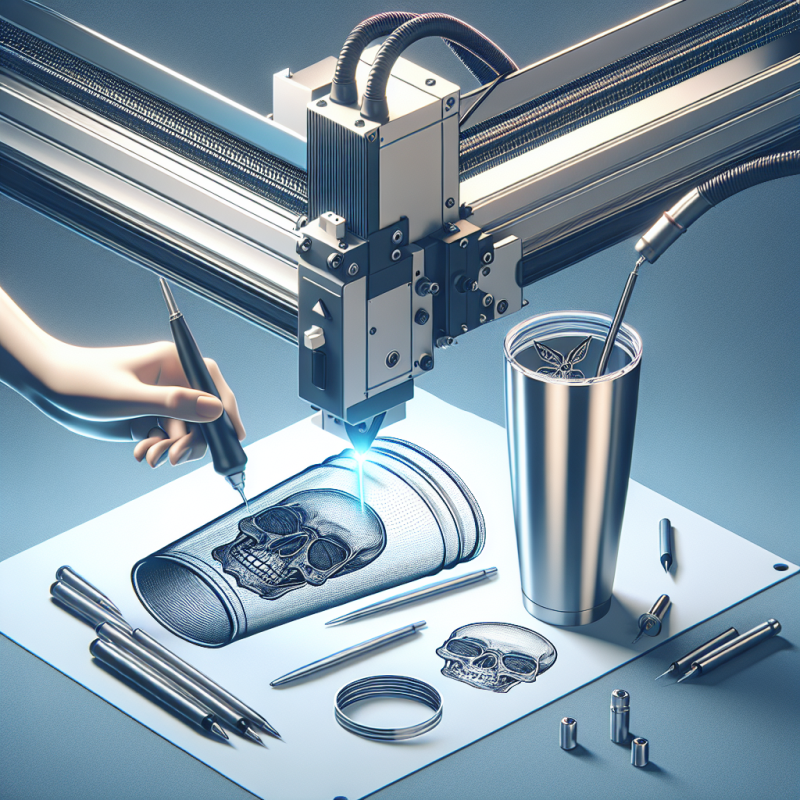

Laser engraving technology employs a concentrated laser beam to etch patterns or images onto different materials. By focusing a high-powered laser onto the surface, the machine systematically removes layers, crafting intricate designs. Primary applications encompass jewelry customization, woodworking, leather design, and precision parts manufacturing.

When exploring a laser engraver engraving machine, it is essential to grasp its extensive capabilities. Imagine personalizing gifts, creating intricate art pieces, or labeling equipment with barcodes—all accomplished using a single, versatile tool. This level of flexibility appeals to both hobbyists and professionals.

Machine Specifications and Features

Diving into the specifications of a laser engraver engraving machine is crucial prior to making a purchase. Key features include the power of the laser (measured in watts), engraving area, and maximum speed. Higher wattage enables faster engraving on thicker materials, thereby influencing productivity and work efficiency.

Equally important is the machine’s software compatibility. Many modern engravers come equipped with user-friendly interfaces, making it easier for beginners to design like seasoned professionals. Additionally, connectivity options such as USB and Bluetooth provide flexibility during operations, maximizing the machine’s potential.

Material Compatibility

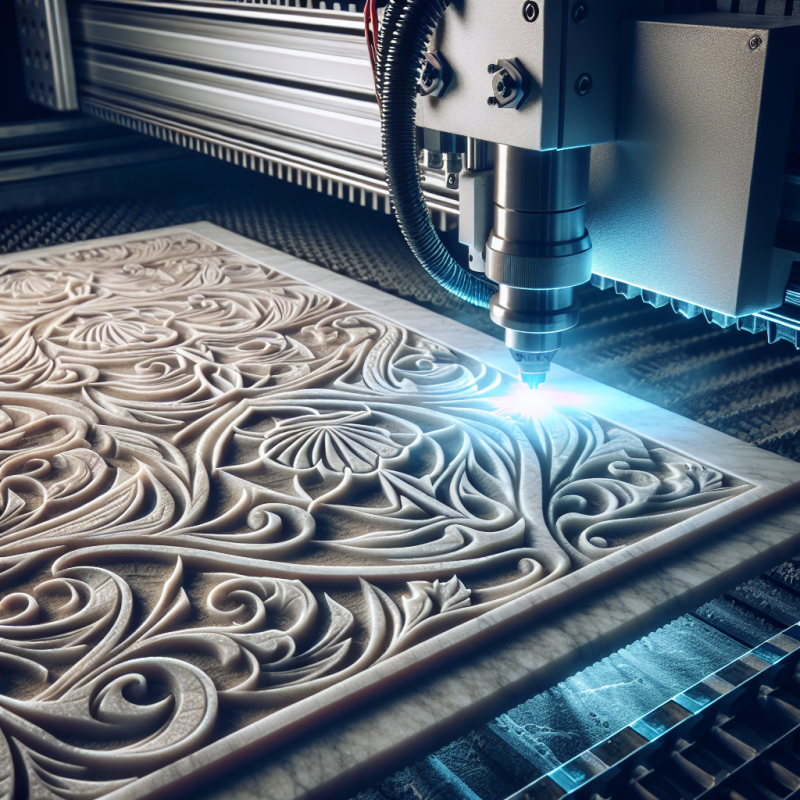

The versatility of a laser engraver engraving machine often hinges on its compatibility with various materials. Commonly engraved materials include wood, acrylic, leather, glass, and specific metals. Before commencing any project, ensuring the chosen material is compatible with the laser engraver is crucial to prevent damage to either the machine or the material.

Understanding material compatibility enhances creativity, enabling users to explore unconventional materials for unique products and outcomes. This ability to work with various substrates increases the machine’s utility across different projects.

Safety Considerations

When operating a laser engraver engraving machine, safety should always be a paramount concern. Ensuring that the workspace is well-ventilated helps avoid inhaling potentially harmful fumes produced during engraving. Moreover, protective eyewear is necessary to shield against laser exposure.

Regular maintenance is crucial to ensure the machine operates safely and efficiently. This includes cleaning lenses, inspecting wiring, and removing fire hazards resulting from debris accumulation around the machine. Following safety protocols helps maintain a secure work environment.

Industry Best Practices

Adhering to industry best practices contributes to prolonging the life and enhancing the performance of your laser engraver engraving machine. Always follow the manufacturer’s guidelines for operation and maintenance. Participating in training sessions or workshops can provide comprehensive operational knowledge and skills tailored to your specific machine model.

Connecting with other users through networking can yield invaluable insights and tips on troubleshooting common issues or optimizing machine capabilities. Communities of users often share experiences that further refine the engraving process.

Cost-Benefit Analysis

The initial investment in a laser engraver engraving machine might seem substantial, but a thorough cost-benefit analysis often reveals its long-term value. The capacity for high-precision engravings done quickly and reliably can significantly amplify potential returns. Furthermore, the machine’s adaptability across various projects and materials minimizes the necessity of purchasing multiple devices.

Investing in such technology ultimately leads to enhanced productivity and greater opportunities for creativity and innovation.

Maintenance Tips

To ensure the durability and efficient performance of your laser engraver engraving machine, proper maintenance is essential. Regularly cleaning optical lenses and inspecting the laser tube for any signs of wear promotes longevity. Additionally, checking the cooling system and filters is vital for avoiding overheating and prolonging the lifespan of the laser system.

Updating the software periodically is also necessary to keep the engraver’s features current; updates can enhance performance and introduce new functionalities to improve your engraving capabilities.

Project Ideas and Tutorials

When utilizing a laser engraver engraving machine, the inspiration for projects is nearly limitless. Here are some intriguing project ideas to consider:

- Create personalized jewelry or home décor items.

- Develop educational tools or 3D puzzles for children.

- Engage in artistic endeavors by crafting sketches and designs on various surfaces.

- Produce custom business merchandise, such as branded keychains or coasters.

A wealth of online tutorials and courses exists to guide users through the art of laser engraving, imparting foundational skills and advanced techniques to refine their craftsmanship. These resources help beginners become proficient quickly.

Conclusion

Overall, the laser engraver engraving machine presents a multitude of possibilities and advantages for creative professionals, hobbyists, and businesses alike. By developing a comprehensive understanding of the machine and following best practices, users can maximize their investment, achieving impressive and personalized outputs.