Exploring the World of Refurbished Laser Engravers

Introduction

In today’s rapidly evolving world of technology, laser engraving machines stand out as innovative tools that have transformed various industries. Among these, a refurbished laser engraver offers a cost-effective solution, blending cutting-edge technology with affordability. As you delve into this article, you’ll discover the numerous benefits and applications of these machines, as well as essential tips for using them effectively.

Understanding Laser Engraving Technology

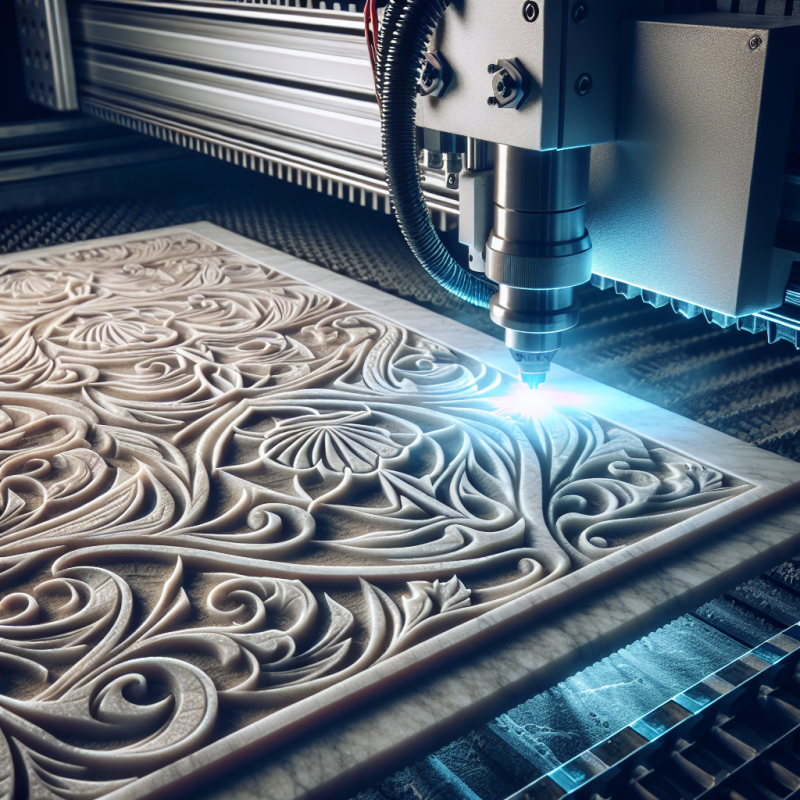

Laser engraving technology uses focused laser beams to etch precise images, patterns, or text onto a wide array of materials. This technology showcases its versatility in industries ranging from jewelry making to industrial manufacturing. A particularly interesting aspect of a refurbished laser engraver is its ability to offer high-quality results akin to new models, often at a reduced cost.

Key Features of a Laser Engraver

When considering a refurbished laser engraver, it’s vital to understand its features:

- Precision and Speed: Laser engravers are known for their high precision, achieving intricate and detailed designs with a quick turnaround.

- Versatility: These machines can engrave on various materials, including metal, wood, acrylic, and leather, making them ideal for multiple applications.

- User-Friendly Interface: Modern laser engravers come with intuitive software that aids users in creating complex designs effortlessly.

- Portability: Compact models are available, making it easy to transport and use the machine in different settings.

Material Compatibility

One of the standout features of a refurbished laser engraver is its compatibility with a variety of materials. Whether you’re a hobbyist working with leather or an industrial designer engraving on metal, these machines cater to all needs. The technology adapts to process diverse substrates effectively, ensuring quality finishes without damaging the raw material.

Safety Considerations

Safety is of utmost importance when using a laser engraving machine. Always wear protective eyewear when operating the engraver, as laser light can damage eyesight. Ensure the work area is well-ventilated to prevent the accumulation of fumes and gases emitted during engraving. Regularly maintain the machine to avoid technical malfunctions that could pose safety risks.

Industry Best Practices

To make the most out of your refurbished laser engraver, adhere to industry best practices:

- Regular Calibration: Keep your machine calibrated to ensure accuracy and efficiency in your designs.

- Material Testing: Conduct small tests on materials before full-scale projects to optimize settings and avoid errors.

- Software Familiarity: Acquaint yourself with the machine’s software to utilize all available features for the best outcomes.

Cost-Benefit Analysis

Purchasing a refurbished laser engraver involves a cost-benefit analysis that weighs financial savings against performance. While these machines are more affordable than newer models, they still offer top-notch functionality and longevity. Investing in refurbished equipment can lead to significant cost savings, especially for small businesses and hobbyists not requiring the latest model.

Maintenance Tips

Proper upkeep of your laser engraver enhances its durability and performance. Regular cleaning of the lens, mirrors, and work area prevents residue buildup, ensuring clarity and precision in engravings. Periodically inspect all moving parts and replace any worn-out components promptly to maintain optimal operation. Adequate lubrication facilitates smooth motion, reducing wear and tear.

Project Ideas and Tutorials

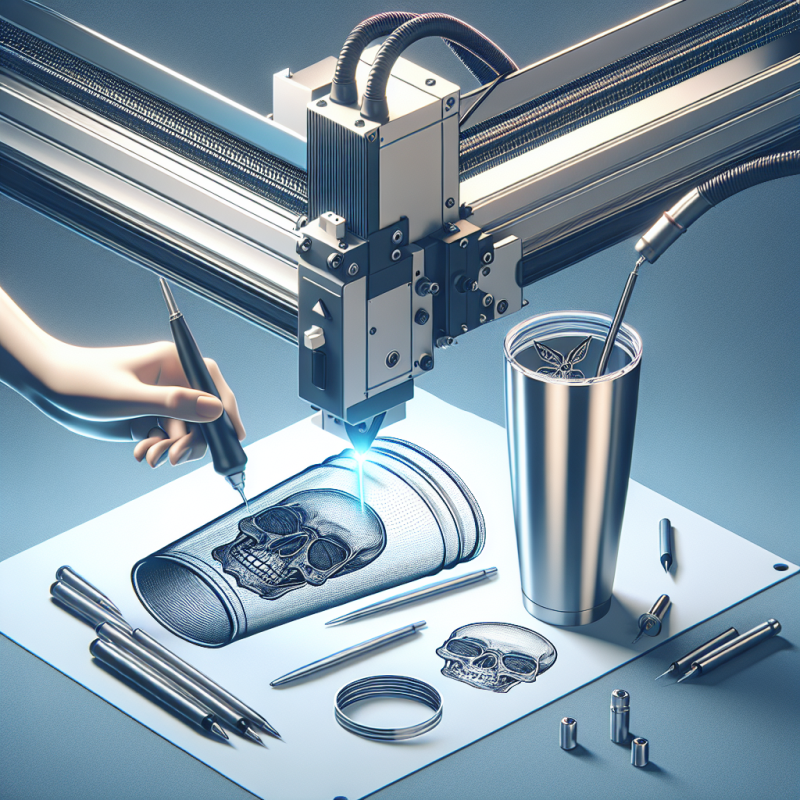

An exciting aspect of owning a refurbished laser engraver is the myriad of possible projects:

- Customized Gifts: Craft personalized gifts such as engraved photo frames, keychains, or bookmarks to add a personal touch.

- Home Décor: Create unique home décor pieces, including decorative wall panels or intricately designed coasters.

- Prototyping: Engineers and designers can use these machines to quickly prototype parts and gadgets for iterative testing.

**Tutorials** and guides are widely available online, offering step-by-step instructions for various projects, enabling users to maximize their laser engraver’s potential.

Frequently Asked Questions

Here are some questions that potential buyers and users often have about laser engraving machines:

What materials can I engrave with a refurbished laser engraver?

Depending on the model, you can engrave a range of materials such as metal, glass, wood, acrylic, leather, and plastic.

How do I choose the right laser engraver for my projects?

Consider factors such as the types of materials you work with, the level of detail required in your engravings, and your budget constraints.

Are refurbished laser engravers reliable?

Yes, if purchased from a reputable source, refurbished laser engravers can be as reliable as new ones, providing great value for money.

How often should I maintain my laser engraver?

Routine maintenance, including cleaning and inspections, should be conducted regularly, with comprehensive servicing done based on usage frequency.

Conclusion

Investing in a refurbished laser engraver can significantly enrich your creative and professional endeavors. With its versatility, efficiency, and cost-effectiveness, it stands as a valuable asset in any workshop. By understanding its features, adhering to safety protocols, and following best practices, you can unlock unlimited possibilities in laser engraving, turning your ideas into tangible works of art.