Laser Engraver for Stone: Precision Engraving Guide

Introduction

In the realm of modern manufacturing and personalized design, laser engraver for stone stands out as a technology that combines precision with versatility. As a professional in the field of laser engraving, I am excited to share insights into how these machines are revolutionizing the way we work with stone. From the intricate artistry of custom designs to their robust applications in various industries, the laser engraver has become an indispensable tool.

Laser Engraving Technology and Applications

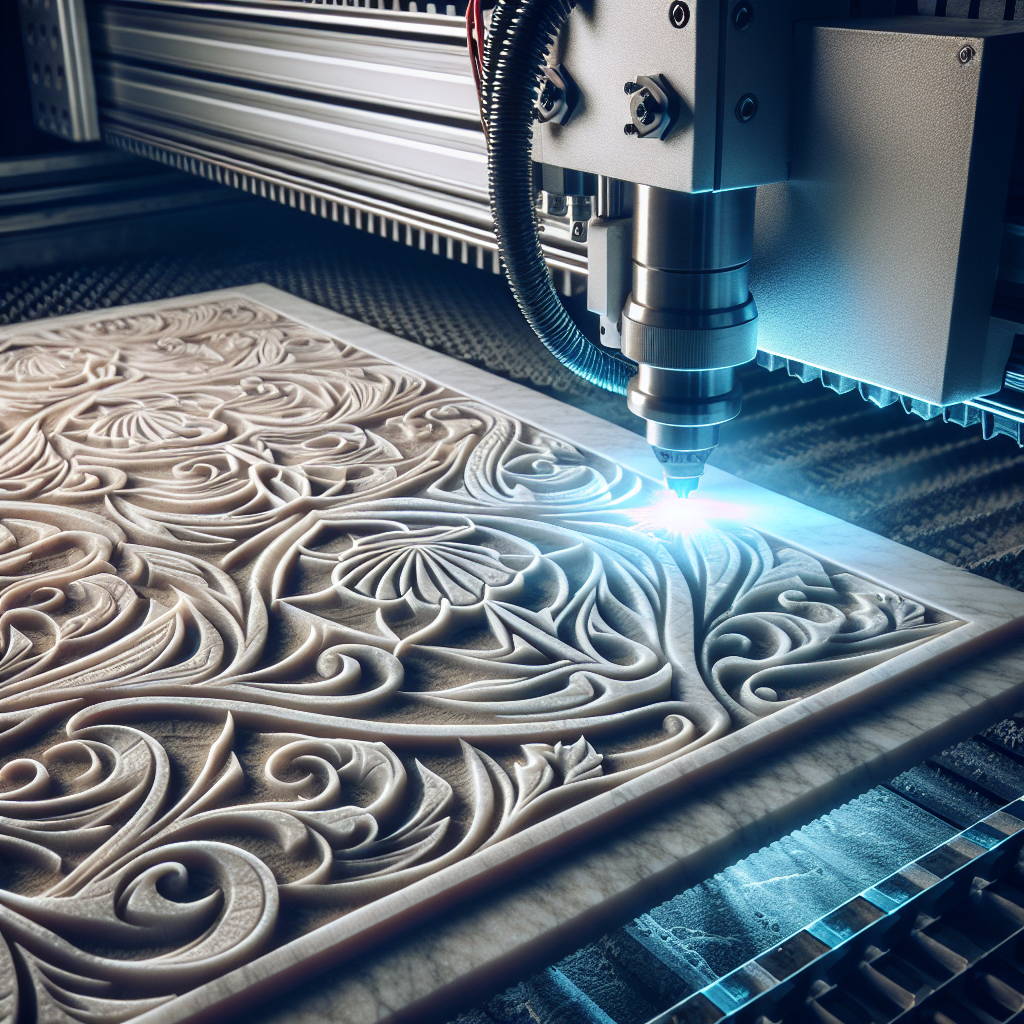

Laser engraving technology uses high-powered lasers to etch or carve designs onto materials. The laser engraver for stone is particularly effective due to stone’s natural durability and resilience. This makes it ideal for a wide range of applications, from creating personalized gifts and commemorative plaques to engraving detailed architectural elements and artistic installations.

With the ability to achieve high precision, laser engravers can produce detailed patterns and text that would be impossible to craft by hand. Industries ranging from jewelry making to construction have embraced this technology to enhance their products and projects.

Machine Specifications and Features

The specific features of a laser engraver for stone are crucial to its performance. Typically, these machines offer a high wattage laser beam that can efficiently engrave hard surfaces like granite, marble, and slate. Depending on the model, users can enjoy benefits like adjustable laser power, precision control, and compatibility with various software systems for design and layout.

Advanced models also provide features such as high-speed engraving capabilities, which minimize project turnaround time, and user-friendly interfaces that make them accessible to both beginners and experienced professionals.

Material Compatibility

One of the main advantages of using a laser engraver for stone is its material versatility. While stones like marble and granite are common choices, these machines also work effectively with semi-precious stones such as jade or obsidian. The ability to handle a variety of hardness levels means that the engraver has broad applications in diverse projects.

However, each type of stone may require specific laser settings to achieve optimal results. The surface finish, thickness, and density of the stone can affect the engraving process. Thus, understanding your material is crucial for ensuring precision and quality in your designs.

Safety Considerations

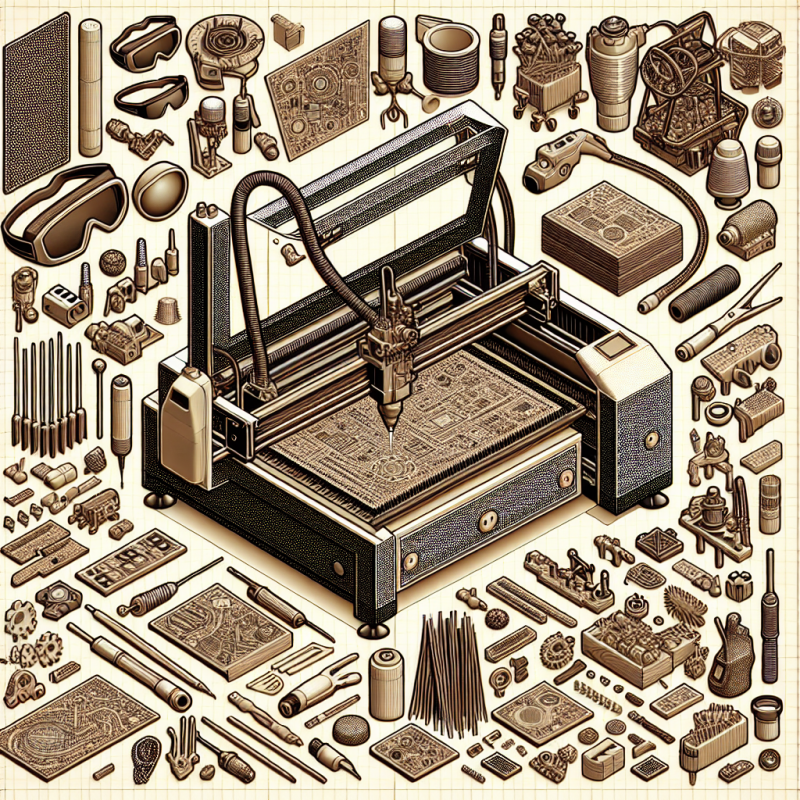

When operating a laser engraver for stone, safety is paramount. Laser beams can pose serious risks to the eyes and skin if exposure occurs without appropriate protection. Ensuring that you are using the correct safety gear, including laser-resistant goggles and gloves, is imperative when working with these machines.

Moreover, good ventilation in the working area is necessary to avoid inhaling any dust or fumes that are produced during the engraving process. Integrated exhaust systems can help in maintaining a safe and clean working environment.

Industry Best Practices

To maximize the capabilities of a laser engraver for stone, it is important to develop best practices. Starting with designing in compatible software programs can streamline your workflow. Practices such as cleaning your machine regularly, calibrating laser settings according to stone type, and performing routine maintenance checks can significantly enhance performance and lifespan.

Collaborating with suppliers or other professionals about best practices can provide new insights and methods to improve the quality of engraving.

Cost-Benefit Analysis

The initial investment in a laser engraver for stone can be substantial. However, when you consider the long-term benefits such as increased productivity, precision customization, and reduced labor costs, the purchase can be justified. Additionally, the ability to offer unique, high-quality products can lead to increased business opportunities and profitability.

When assessing cost-effectiveness, potential users should consider factors such as machine durability, energy consumption, and the availability of technical support and service.

Maintenance Tips

Maintaining your laser engraver for stone is crucial for prolonging its lifespan and ensuring consistent performance. Regularly cleaning components such as the laser lens and mirrors will prevent dust and debris accumulation, which can affect the efficiency of the laser beam and result in inferior etchings.

Also, inspecting the machine for any signs of wear or damage, especially after extensive use, can prevent costly repairs and downtime. Lubricating moving parts and checking the alignment are components of a comprehensive maintenance routine.

Project Ideas and Tutorials

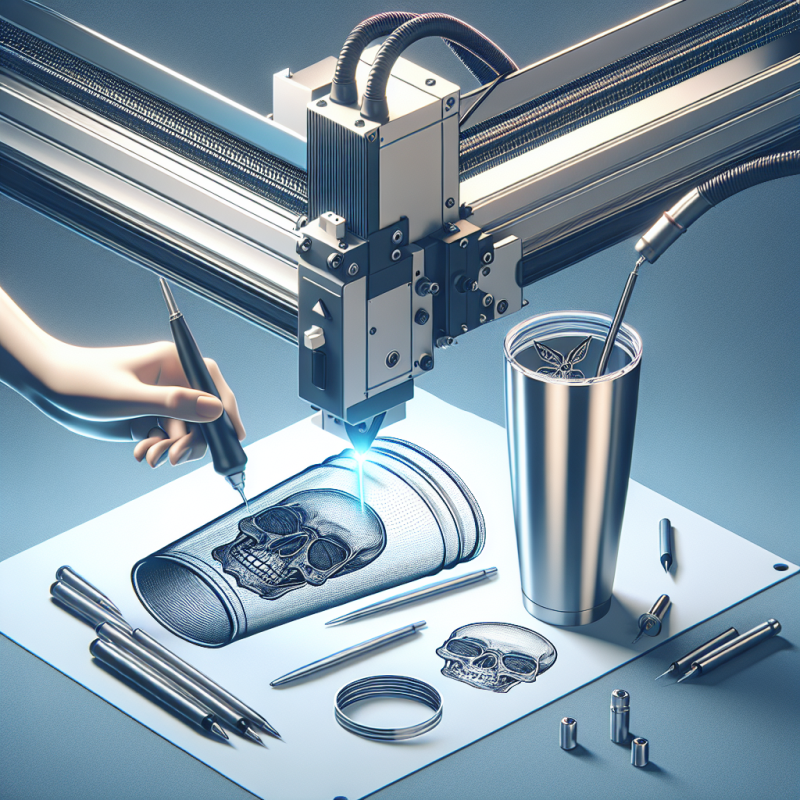

For those looking to explore creative avenues with a laser engraver for stone, there are endless project ideas to consider. From creating custom jewelry pieces to crafting personalized home décor items, the only limit is your imagination. Tutorials abound online, offering step-by-step guides for beginners and advanced users alike to hone their skills and create stunning works of art.

Engaging in such projects not only broadens creative expression but also qualifies as a hands-on method to learn the intricate settings and capabilities of your laser engraving machine.

Conclusion

The impact of a laser engraver for stone on craftsmanship and industrial applications is undeniable. Whether you are a hobbyist looking to explore creativity or a business aiming to enhance production, understanding the full potential of this tool is crucial. By keeping informed on machine features, safety precautions, and maintenance practices, users can achieve high-quality results while taking full advantage of this remarkable technology.