Metal Laser Cutter: A Deep Dive into Laser Engraving Machines

Introduction

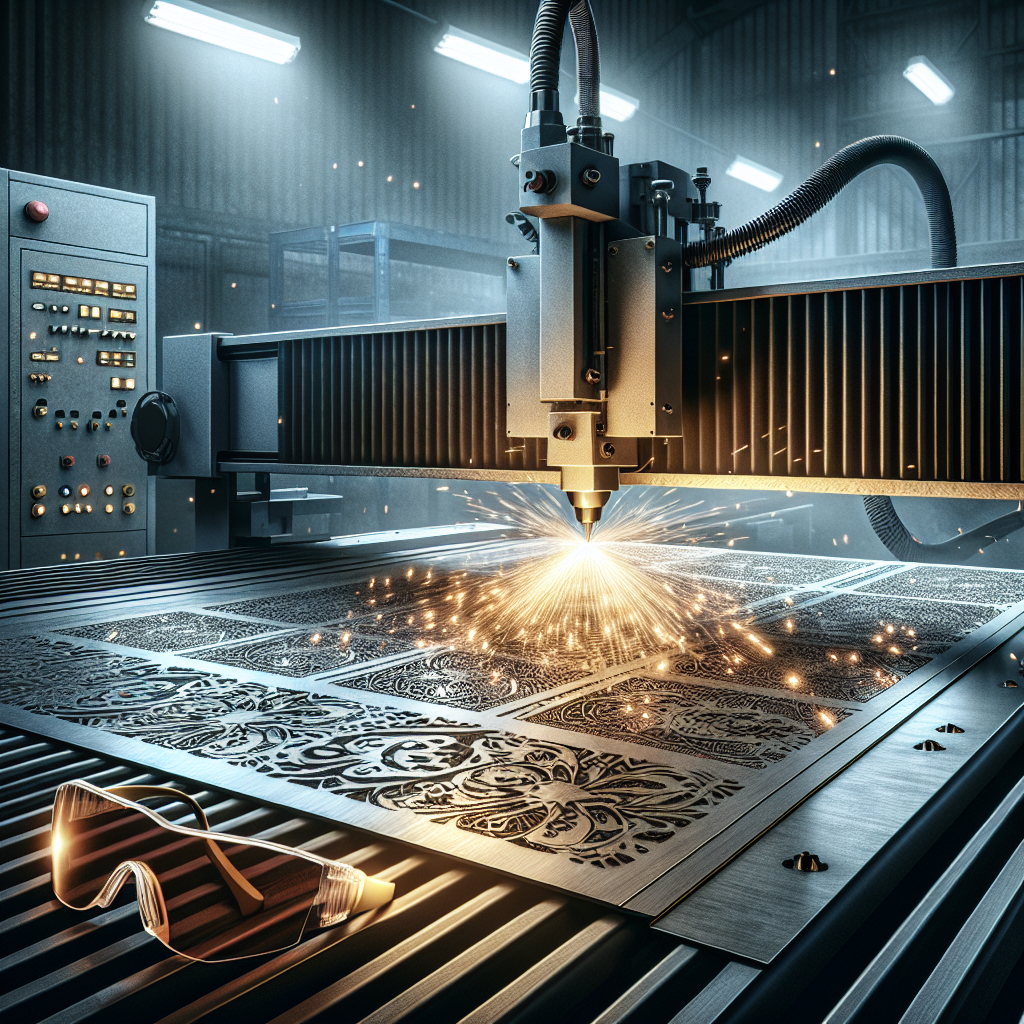

In the world of precision engineering and creative design, the metal laser cutter has emerged as an essential tool. Offering unparalleled accuracy and versatility, laser engraving technology has revolutionized various industries. Whether you’re a seasoned professional or a dedicated hobbyist, understanding the intricacies of laser engraving machines is vital for maximizing their potential. This article explores the diverse aspects of metal laser cutters, highlighting their applications, key specifications, safety considerations, maintenance tips, and more.

Understanding Laser Engraving Technology

Laser engraving uses laser technology to etch patterns, designs, or text onto surfaces. The laser beam operates like a chisel, vaporizing layers of material to achieve the desired pattern. One primary advantage of a metal laser cutter is its capacity to produce precise and intricate designs without direct contact with the surface.

What sets laser engraving apart? It offers speed, precision, and flexibility, allowing customization that other methods cannot match. Ensuring a clean finish, it finds extensive use in jewelry design, automotive parts manufacturing, and the creation of personalized gifts.

Machine Specifications and Features

When selecting a metal laser cutter, understanding its specifications is crucial for achieving the desired results.

- Power: The laser’s power rating determines its capacity to cut through different material thicknesses. Higher wattage lasers can penetrate thicker materials but often require more cooling and power consumption.

- Speed: Cutting and engraving speeds impact productivity. Machines with adjustable speeds can manage different tasks more effectively.

- Resolution: DPI (dots per inch) influences engraving precision. Higher resolutions provide finer detail but may require longer processing times.

- Workspace Size: The dimensions of the machine’s workspace define the maximum size of the material that can be engraved or cut.

- Software Compatibility: User-friendly software is vital for designing and transferring patterns to the machine. Some metal laser cutters include proprietary software, ensuring seamless integration.

Material Compatibility

The versatility of a metal laser cutter makes it suitable for a wide variety of materials. From metals like stainless steel, aluminum, and brass to non-metals such as wood, plastic, leather, and glass, these machines offer diverse applications.

Can a metal laser cutter work on all metal types? Nearly any metal can be engraved, but factors like material thickness and laser power must be considered for optimal results. The choice of metal also affects the finish and durability of the engraving.

Safety Considerations

When using a high-powered metal laser cutter, safety is paramount. Here are some essential safety tips:

- Laser Safety Goggles: Always wear goggles to protect your eyes from the laser beam.

- Ventilation: Adequate ventilation is necessary to remove harmful fumes produced during laser engraving.

- Fire Safety: Keep a fire extinguisher within reach, as certain materials can catch fire under high heat.

- Secure Work Area: Ensure the work area is free from flammable objects and distractions.

Are there specific procedures for handling laser engravers? Yes, always follow the manufacturer’s guide for setup, use, and maintenance to ensure safety and prolong the machine’s life.

Best Practices

To optimize the use of a metal laser cutter, adopting industry best practices is advisable.

Ensure regular software updates for the engraver and associated design programs to leverage improvements and added functionalities. Regular training and skill development workshops can also help operators stay at the forefront of laser engraving technology.

Cost-Benefit Analysis

Investing in a metal laser cutter requires a careful cost-benefit analysis. Although the initial costs can be substantial, the efficiency and precision these machines offer often result in significant long-term savings and enhanced productivity.

Consider the following:

- If the volume of work is substantial, the decreased labor cost and increased precision can quickly offset the machine’s expense.

- Customization capabilities can open new revenue streams in markets demanding personalized products.

- Efficient use of materials and minimal waste also contribute to cost savings.

Maintenance Tips

Regular maintenance is crucial for any laser engraver to function optimally over time. Here are some maintenance tips:

- Cleaning: Regularly clean the lens and mirrors to avoid residue buildup that can affect laser performance.

- Alignment: Check laser alignment periodically to ensure consistent results.

- Cooling System: Ensure the cooling system is running efficiently to prevent overheating.

- Software Updates: Keep the machine’s software and firmware up-to-date to incorporate the latest enhancements.

Project Ideas and Tutorials

The creative potential of a metal laser cutter is virtually limitless. It can be used to create:

- Custom jewelry designs

- Personalized home decor items

- Intricate architectural models

- Unique business signage

- Branded corporate gifts

Online tutorials and design templates can kickstart your projects, allowing you to explore various techniques and applications of laser engraving.

Conclusion

The journey through the world of metal laser cutters reveals their profound impact across industries. From enhancing creative endeavors to streamlining complex manufacturing processes, these machines are invaluable assets. By understanding their technology, specifications, and best practices, users can fully harness the power of laser engraving. Whether driven by hobby or profession, the potential applications of laser technology promise endless possibilities for artistic expression and industrial innovation.