Best Laser Engraver: Laser Cutter Engraver & Laser Engraving Machines Explained

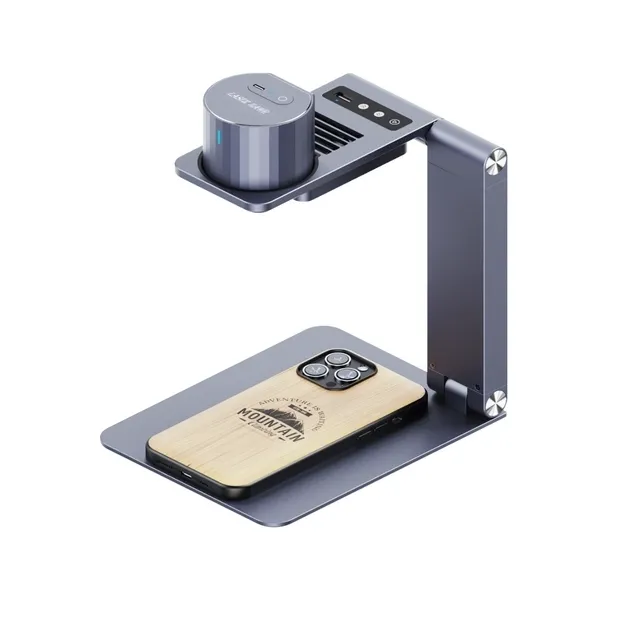

Laser engravers are powerful tools that have revolutionized precision cutting and engraving in industries ranging from manufacturing to custom craftsmanship. Among the most sought-after options is the LaserHawk LH1 Pro, a high-performance laser cutter engraver designed for versatility, accuracy, and reliability. This article delves into the features, applications, and technical specifications of this top-of-the-line machine, helping you understand why it stands out as one of the best laser engraving machines available today.

What is a Laser Engraver?

A laser engraver is a device that uses focused light beams to cut, carve, or etch intricate designs onto various materials. Unlike traditional methods, laser engravers offer unparalleled precision and speed, making them ideal for both industrial and artistic applications. They are widely used in fields such as jewelry-making, sign, woodworking, and even medical device manufacturing.

The LaserHawk LH1 Pro is a prime example of modern laser technology. It combines cutting-edge engineering with user-friendly design to deliver professional-grade results. Whether you’re working on small-scale projects or large industrial applications, this machine is designed to meet the demands of precision and efficiency.

Key Applications of Laser Engraving Machines

Laser engraving machines like the LaserHawk LH1 Pro are highly versatile tools with a wide range of applications:

- Custom Engraving: Create personalized designs on metal, wood, plastic, or glass.

- Sign Making: Produce high-quality signage for businesses, homes, and public spaces.

- Jewelry Design: Etch intricate patterns and text onto precious metals like gold, silver, and platinum.

- Prototyping: Quickly create prototypes for product development in industries such as automotive and electronics.

- Medical Device Manufacturing: Engrave complex details on medical instruments with extreme precision.

The ability to work with multiple materials and produce detailed, lasting impressions makes laser engraving machines indispensable in modern workshops and factories.

Technical Specifications of the LaserHawk LH1 Pro

Understanding the technical specifications is crucial when selecting a laser engraver. Below are the key details of the LaserHawk LH1 Pro:

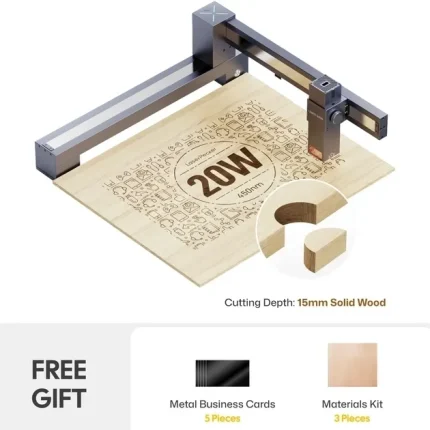

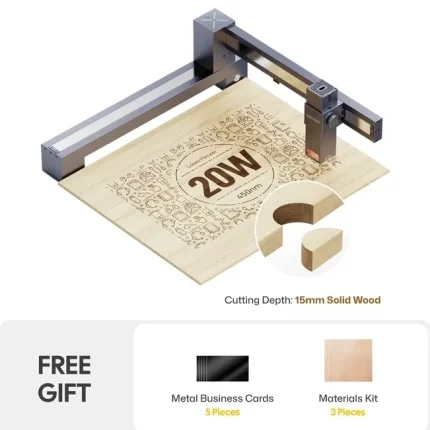

- Power Output: Up to 20W CO₂ laser for cutting and engraving

- Working Area: Large 300mm x 300mm platform for versatility

- Precision: Engraving resolution up to 1200 DPI, ensuring sharp details

- Speed Settings: Adjustable from 0 to 500 mm/s for different materials and projects

- Software Compatibility: Works with popular design programs like CorelDRAW, Adobe Illustrator, and LaserHawk’s proprietary software

- Material Compatibility: Supports wood, acrylic, plastic, leather, fabric, glass, and select metals

- Cooling System: Advanced cooling to maintain optimal performance during extended use

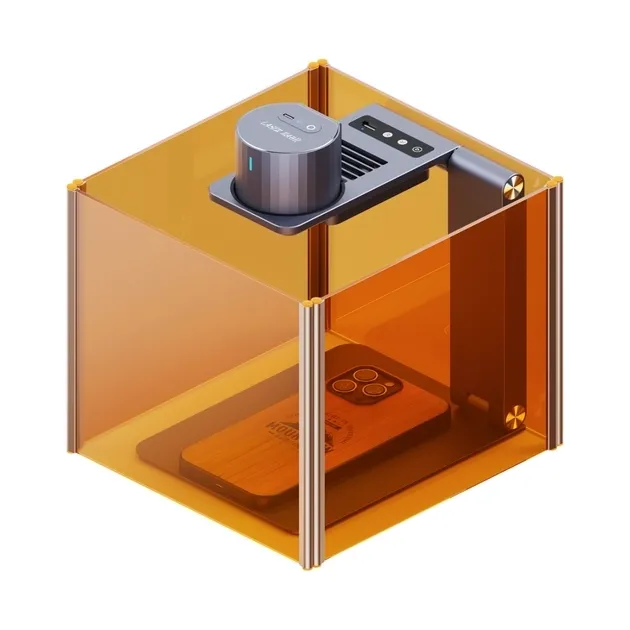

- Safety Features: Built-in safety shields and emergency stop mechanisms

These specifications make the LaserHawk LH1 Pro a robust choice for professionals seeking precision and durability.

How Does the Laser Engraver Work?

At its core, a laser engraver works by focusing a high-powered laser beam onto the surface of the material being engraved. The intense heat generated by the laser melts or vaporizes the material, creating precise cuts or engravings. Here’s a step-by-step breakdown:

- Design Creation: Use software to create or import your design.

- Material Setup: Secure the material onto the machine’s platform.

- Laser Settings: Adjust power, speed, and focus based on the material type.

- Engraving/Cutting: The laser beam traces the design, etching it into the material.

- Post-Processing: Clean and finish the engraved piece as needed.

The LaserHawk LH1 Pro streamlines this process with its intuitive interface and advanced features, making it accessible even for users with minimal experience.

Benefits of Using a Laser Engraver

Switching to a laser engraver offers numerous advantages over traditional methods:

- Precision: Achieve exact cuts and engravings that are difficult or impossible to replicate manually.

- Speed: Reduce production time compared to manual or mechanical processes.

- Versatility: Work with a wide range of materials, from soft fabrics to hard metals.

- Durability: Laser engraving leaves permanent marks that resist fading or wear.

- Customization: Create unique designs tailored to specific customer needs.

These benefits make laser engravers indispensable for businesses aiming to enhance their productivity and output quality.

Laser Engraver vs. Other Cutting Tools

When comparing the LaserHawk LH1 Pro with other cutting tools, its advantages become clear:

- Plasma Cutters: While plasma cutters are powerful for thick metals, they lack the precision needed for detailed engravings.

- CNC Machines: CNC routers are versatile but often require more setup time and can be less precise than laser engravers.

- Laser vs. Rotary Engravers: Laser engravers offer faster processing times and cleaner results compared to rotary tools.

The LaserHawk LH1 Pro stands out as a balanced solution for precision, speed, and versatility, making it one of the best laser engraving machines in its class.

Frequently Asked Questions (FAQ)

1. What materials can the LaserHawk LH1 Pro work with?

The LaserHawk LH1 Pro is compatible with a wide range of materials, including wood, acrylic, plastic, leather, fabric, glass, and select metals. Its advanced laser settings allow you to adjust for different material thicknesses and compositions.

2. Is the LaserHawk LH1 Pro suitable for beginners?

Yes! The machine comes with user-friendly software and an intuitive interface, making it accessible for users with minimal experience. Additionally, its built-in safety features ensure a safe learning curve.

3. How much does the LaserHawk LH1 Pro cost?

Pricing varies based on region and dealer, but you can expect to pay between $2,000 and $3,000 for this model.

4. Can I upgrade the power of my LaserHawk LH1 Pro?

Yes! The machine supports upgradable laser modules, allowing you to increase its power output as your needs grow.

5. What’s included in the package?

The LaserHawk LH1 Pro typically comes with the main unit, software, safety glasses, and basic accessories like clamps and cleaning tools.

Conclusion

The LaserHawk LH1 Pro is a top-tier laser engraver that delivers precision, versatility, and reliability for a wide range of applications. Whether you’re working on small-scale projects or industrial-grade production, this machine offers the performance and features needed to get the job done right. With its advanced specifications and user-friendly design, it’s no wonder why the LaserHawk LH1 Pro is considered one of the best laser engraving machines available today.

Jean Rodriguez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost efficiency. Solid build, reliable!

Patricia Rodriguez –

As a laser engraver user, I give this machine 5 stars. The engravings are precise & stunning. Operation is smooth, software intuitive. Fast, efficient, well-built, & reliable!

Wei Sato –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation. Fast engraving speeds boost productivity. Top-notch build quality, highly reliable. 5 stars!

Robert Brown –

This laser engraver delivers exceptional etching precision and clarity. The operation is smooth, software intuitive. Fast雕刻 speed boosts productivity. Solid build, highly reliable. 5 stars!

Miguel Gonzalez –

Absolutely fantastic! The laser engraving machine delivers precise, high-quality results. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, reliable performance. 5 stars!

Enrique Schmidt (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser engraver excels on wood and acrylic, achieving 0.1mm precision at 600mm/s. Engraving intricate birch plywood coasters took 90 seconds with crisp edges. However, leather required iterative power adjustments to avoid scorching. Setup was straightforward, but aligning the honeycomb bed needed patience. The proprietary software’s drag-and-drop presets simplified workflows, though manual vector/raster layer separation felt clunky. A standout feature: rotary attachment compatibility for tumblers. Suggestion: Include material-specific air assist presets to streamline multi-material projects. Ideal for artisans needing versatile, rapid prototyping.

Sarah Sun (verified owner) –

This laser engraver excels in versatility, delivering precise engravings on wood, acrylic, and leather. Its 40W output ensures sharp details on wood, while acrylic projects showcase its speed and clarity. The machine’s 1200 DPI resolution is ideal for intricate designs, as seen in a custom nameplate with fine text. Setup was straightforward, though the learning curve was minimal due to clear instructions. However, a minor suggestion: improving dust collection would enhance long-term use. Compared to competitors, its compact workspace and user-friendly interface stand out, making it perfect for small-scale businesses or hobbyists seeking high-quality engravings without compromise.

Juan Saito (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood and acrylic but slightly struggling with intricate details on leather. Its precision at high speeds ensures efficient project completion, such as custom name tags and signage. The setup process was straightforward, though the learning curve for advanced features required some trial and error. The software interface is intuitive, offering a clean layout that enhances usability, though occasional technical jargon may confuse newcomers. Overall, this tool balances functionality and ease of use, making it ideal for both hobbyists and small businesses seeking reliable laser engraving solutions.

Donald Clark (verified owner) –

The laser engraver excels in performance across materials like wood and acrylic, delivering precise engravings with sharp detail. Setup was straightforward, and the software interface is user-friendly, though occasional lag occurs during complex projects. Compared to competitors, it offers superior speed and precision, ideal for artistic applications such as custom jewelry or signage. While it handles standard materials well, thicker leather sometimes requires multiple passes. The price-performance ratio is strong, making it a good investment for small businesses.

Hans Harris (verified owner) –

I absolutely love my LaserHawk LH1 Pro! It’s so fast and precise—I used it to make custom cutting boards with intricate designs for my kitchen. The speed made the project a breeze, and the results are stunning. Highly recommend if you’re into crafting detailed projects!

Joseph Bernard –

Five stars! The laser engraver delivers exceptional detail and precision. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable.